Composite geotextile material capillary barrier draining structure and unsaturated loess embankment structure

A drainage structure and composite geotechnical technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems that cannot be completely effectively solved, there is no mature unsaturated seepage drainage technology method, etc., to increase soil layer isolation, improve durability, prevent The effect of rising capillary water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

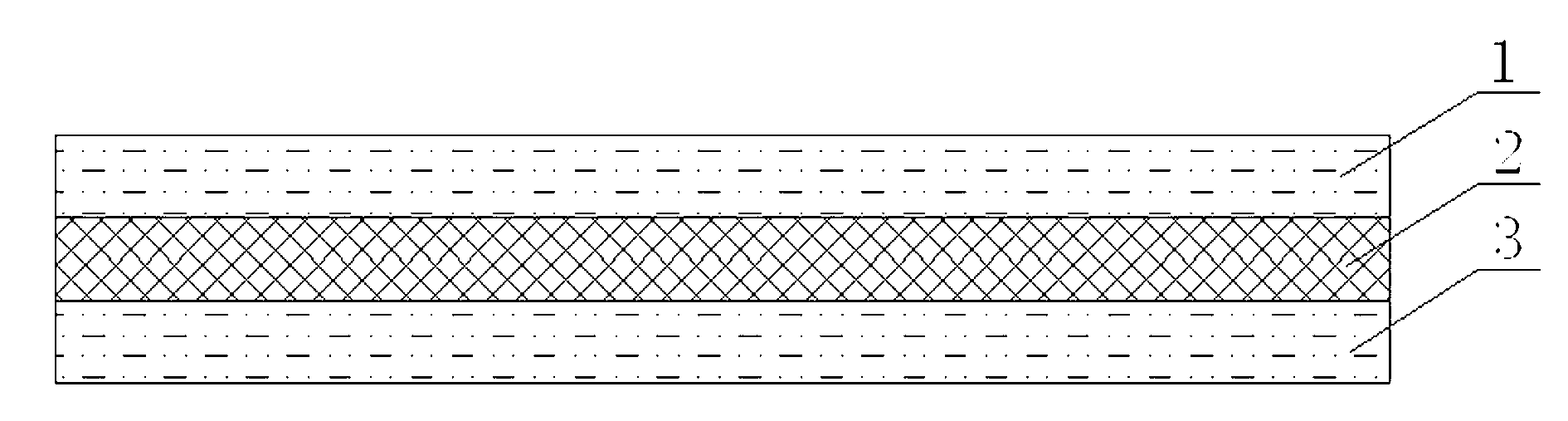

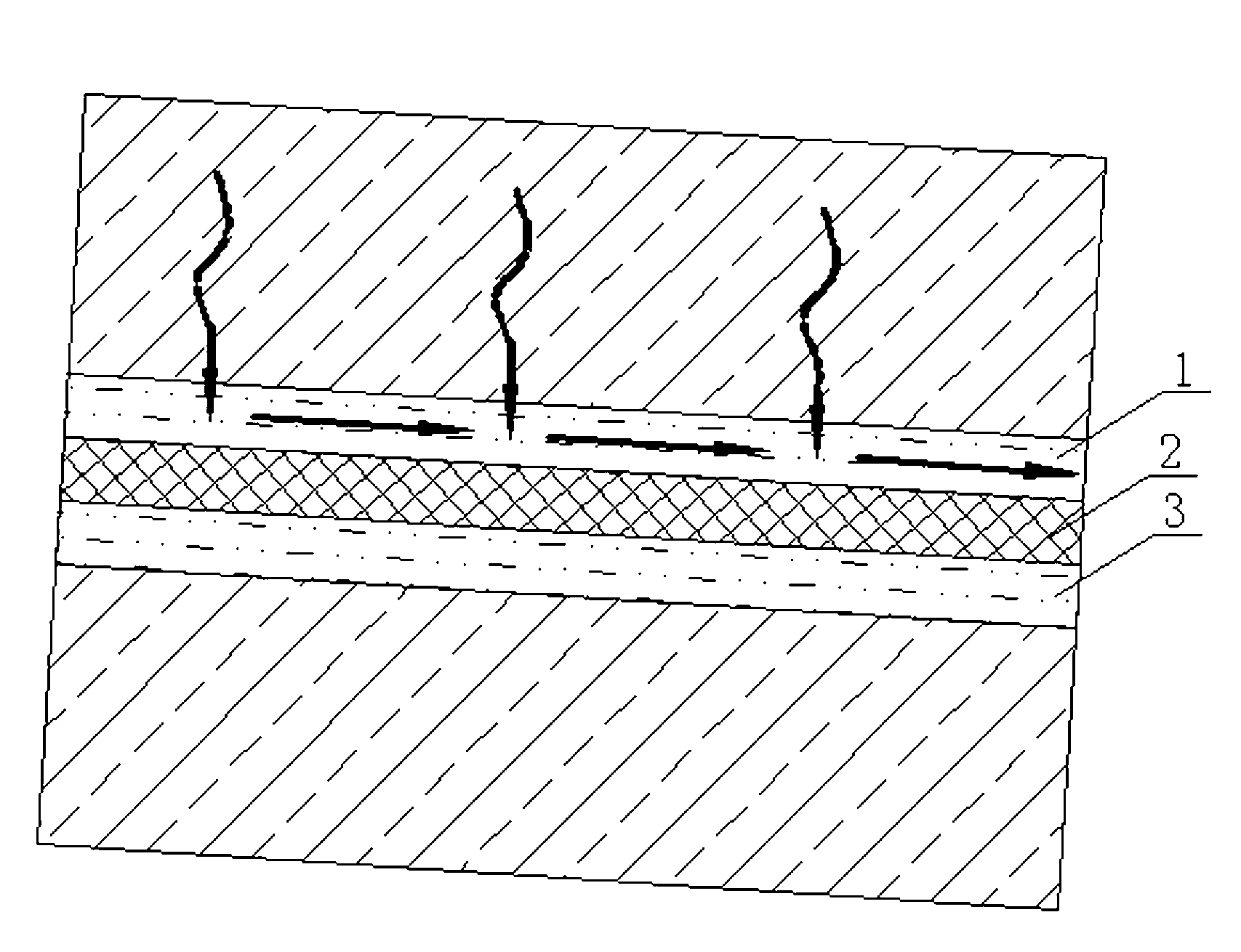

[0017] Such as figure 1 Shown: the composite geotechnical material capillary barrier drainage structure provided by the present invention is made up of three layers; From top to bottom, it is the transmission layer 1, the capillary barrier layer 2 and the isolation layer 3; the transmission layer 1 and the isolation layer 3 are non- The geotextile is woven, and the capillary barrier layer 2 is a geonet.

[0018] The non-woven geotextile of the transmission layer 1 is a filament needle-punched geotextile with a grammage of 200-300 g / m 2 ; The non-woven geotextile of the isolation layer 3 is a filament needle-punched geotextile, and its grammage is 400-500 g / m 2 .

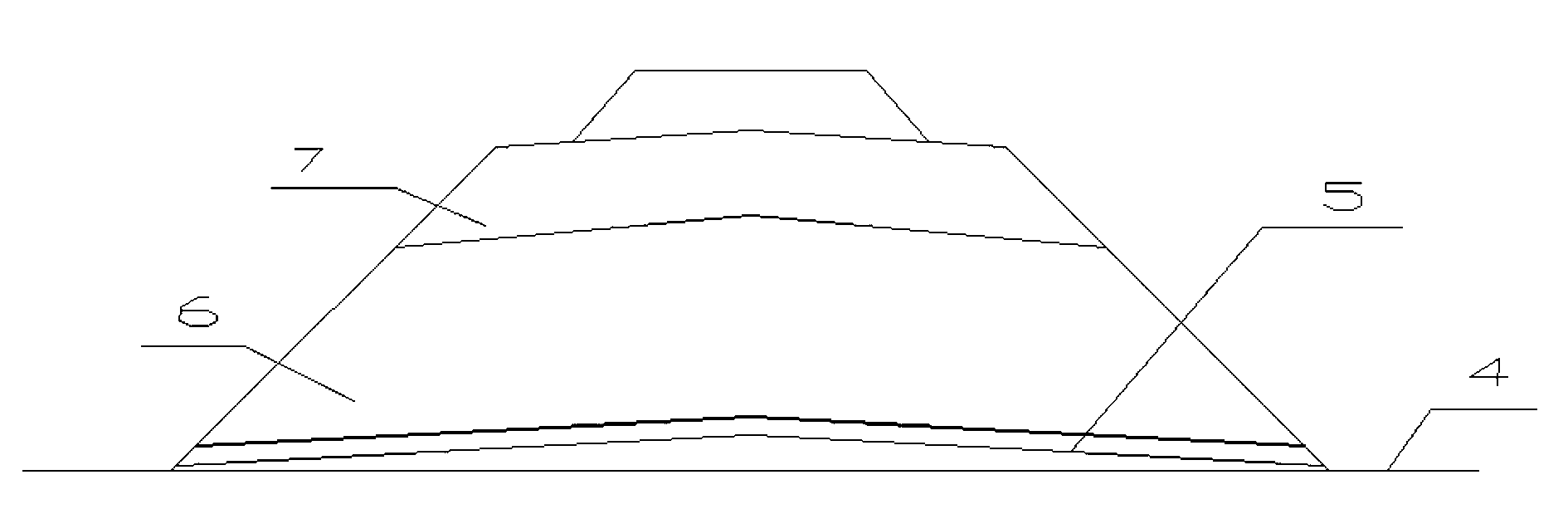

[0019] Such as figure 2 Shown: the unsaturated compacted loess embankment structure provided by the present invention comprises a foundation 4, a roadbed 6 and a bed 7, and a composite geotechnical material capillary barrier drainage structure 5 is arranged between the foundation 4 and the roadbed 6; the foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com