Hydraulic drive system with a plurality of hydraulic pumps and an energy recovery

A drive system, hydraulic pump technology, applied to fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

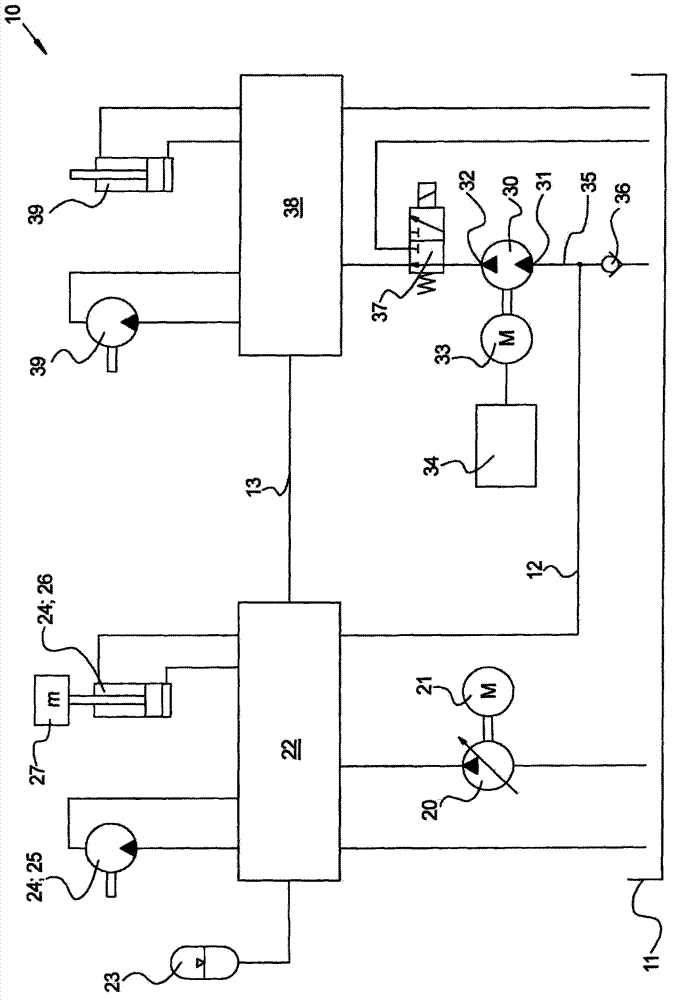

[0020] according to figure 1 The hydraulic drive system 10 includes an oil tank 11 filled with hydraulic fluid, especially hydraulic oil, under ambient pressure. The first hydraulic pump 20 draws hydraulic fluid from the tank 11 for supply to preferably a plurality of first consumers 24 . The first hydraulic pump 20 has an adjustable displacement so that only the fluid flow required by the first consumer 24 can be delivered to avoid energy losses. The first hydraulic pump 20 is preferably designed as a slant-axis or swash-plate machine and is driven by a diesel engine 21 .

[0021] The first consumer 24 is preferably a consumer that performs mechanical work. In particular, consumers are conceivable that carry out various working movements of the mobile work machine (not shown). For example, the hydraulic motor 25 is used for the undercarriage, for the movement of the superstructure which is rotatably movable relative to the chassis or for driving the winch. Hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com