Gas collecting tube assembly, combination method thereof and air conditioning system

A gas collecting pipe and component technology, applied in the field of refrigeration, can solve the problems of difficult air tightness control, poor surface quality, large mutual thermal influence, etc., and achieve the effects of improving air tightness reliability, reducing material costs, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technology of the present invention will be described below in conjunction with specific embodiments.

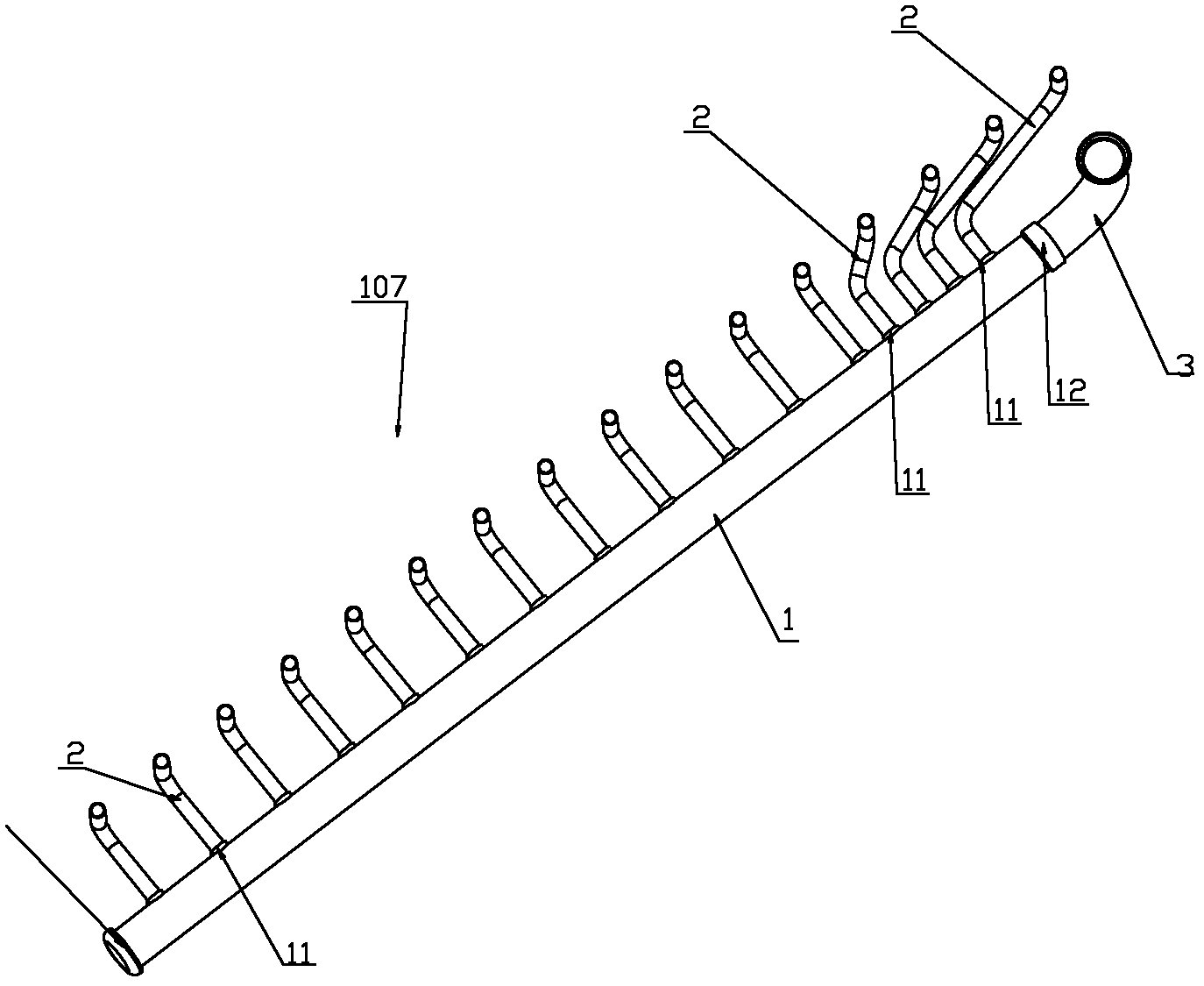

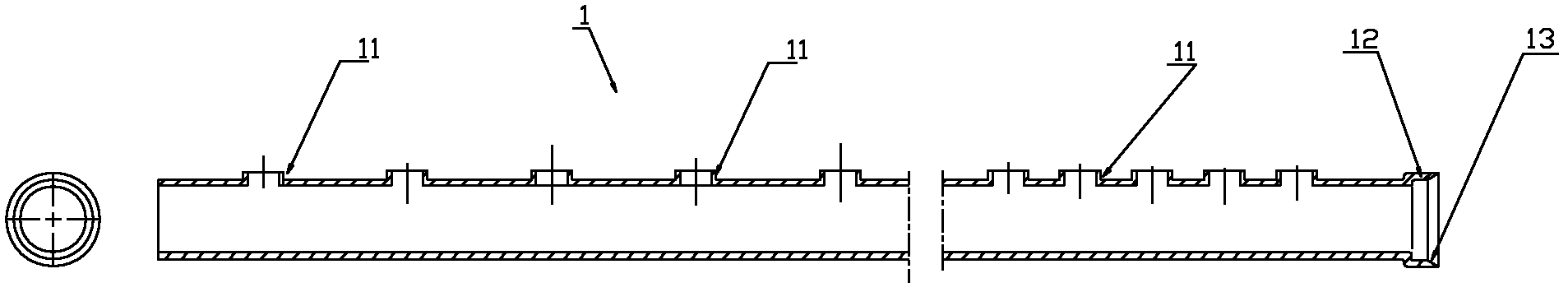

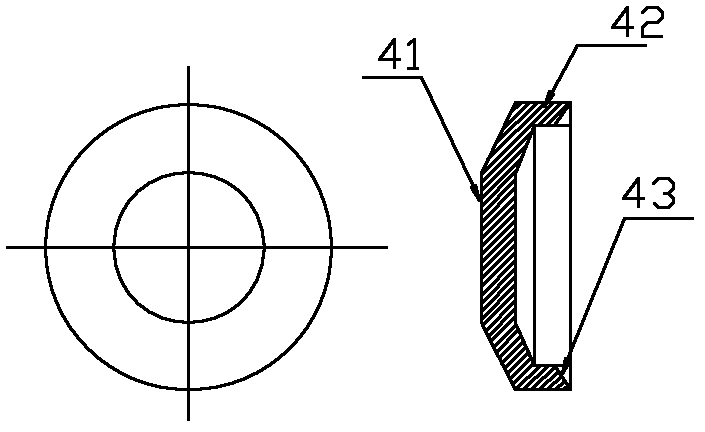

[0044] figure 1 It is a structural schematic diagram of the gas collecting pipe assembly provided by the present invention, figure 2 Schematic diagram of the structure of the main air collector, image 3 Schematic diagram of the structure of the envelope.

[0045] Such as figure 1 , figure 2 with image 3 shown. The air collecting pipe assembly 107 is composed of the main air collecting pipe 1 as the main structure, and several steps 11 are processed on the pipe wall of the main air collecting pipe 1. Or elbows at both ends.

[0046] According to the connection requirements of the air-conditioning system, design and process the branch pipes 2 with different spatial structures. For example, in this embodiment, the branch pipes 2 are bent pipes with different bending angles (of course, they can also be straight pipes). One end of the branch pipe 2 goes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com