Novel intelligent sensor for measuring dust concentration by using laser backscattering method

A smart sensor and dust concentration technology, applied in the field of sensors, can solve problems such as complex production process, failure to meet precision requirements, poor maintainability, etc., achieve simple and reliable optical path structure design, improve stability and accuracy, and prevent optical path pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

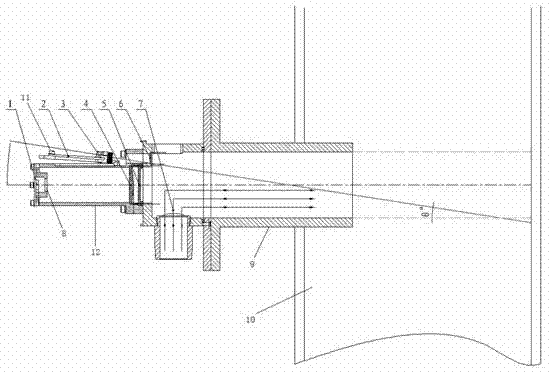

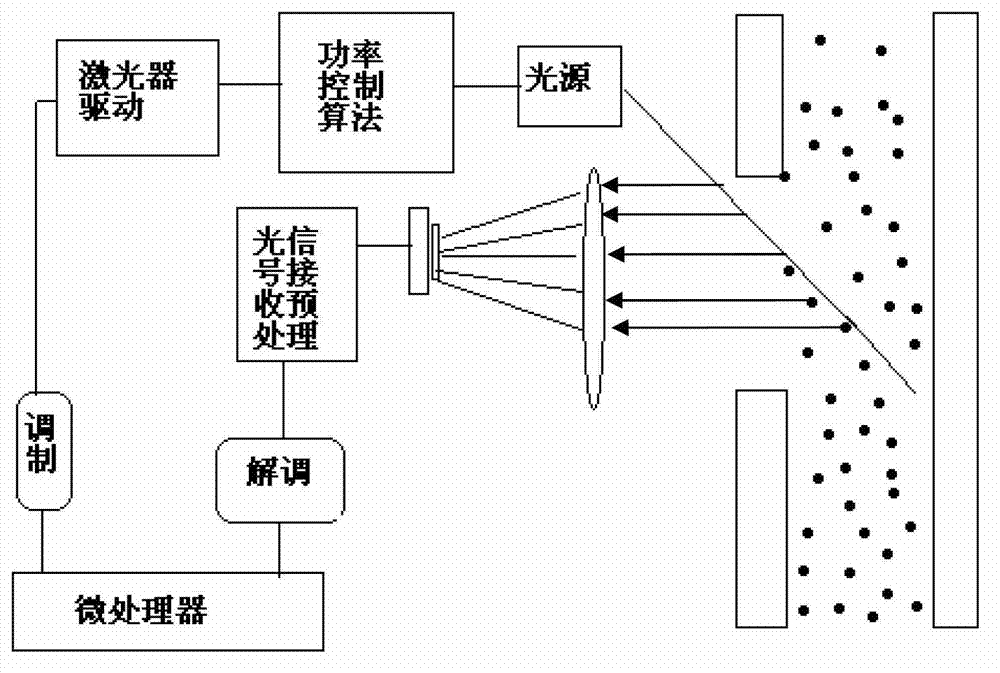

[0015] Such as figure 1 As shown, a novel laser backscattering method for measuring dust concentration intelligent sensor includes a microprocessor 11, a casing 12 with one end open and the other end stepped into a stepped shape, and a flange 9, the flange 9 and the casing 12 One end of the opening is connected and the flange 9 extends into the flue 10. A gas inlet 7 is opened on the side wall of the casing 12, and a connected semiconductor laser is fixed on the outer upper part of the stepped end of the casing 12. Drive circuit board 2 and laser 3, the microprocessor 11 is fixed on the semiconductor laser drive circuit board 2, the microprocessor 11 adjusts the laser 3 to emit laser light, and a window is opened at the second step of the shell 12 A plane mirror 6 is arranged behind the window, and the laser 3 emits laser light at a certain angle through the window and passes through the plane mirror 6 into the flue 10, and the dust in the flue 10 scatters the laser light back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com