Combined oil removing device

A degreaser and combined technology, which is applied in the direction of grease/oily substance/floating matter removal device, liquid separation, separation method, etc., can solve the problem of single degreasing process of degreaser, insufficient oil removal, difficult removal, etc. problem, to achieve the effect of oil-water separation, simple structure, and reduced degree of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

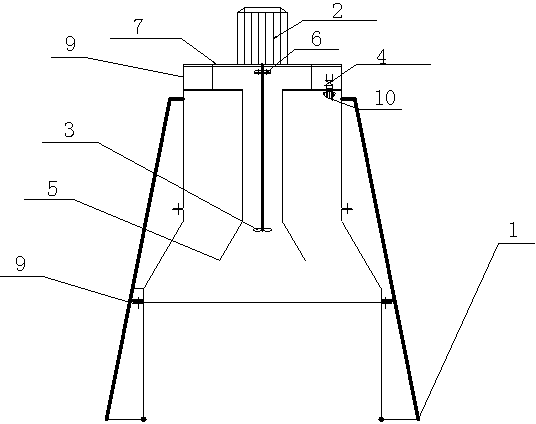

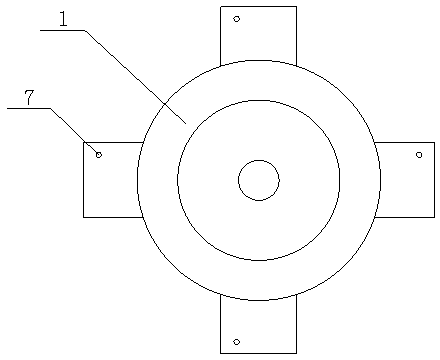

[0014] The invention discloses a combined degreaser, which comprises a frame body 1, a reducer 2 arranged on the top of the frame body, a floating oil collector 3 vertically arranged in the frame body 1 and coaxial with the reducer 2, fixed The oil suction pump 4 on one side of the oil slick collector 3 on the top of the frame body 1; a circle of separation cylinder 5 is arranged around the oil slick collector 3 in the said frame body 1; Below the machine 2; the upper part of the frame body 1 is provided with a group of water injection valves 7, and the lower part of the frame body 1 is provided with a filter plate 8 with evenly dense apertures; the water inlet of the water injection valve 7 is provided with a screen 9, and the separation cylinder 5 A water outlet cap 10 is provided on the top.

[0015] The frame body 1 is a tapered cylinder that gradually becomes lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com