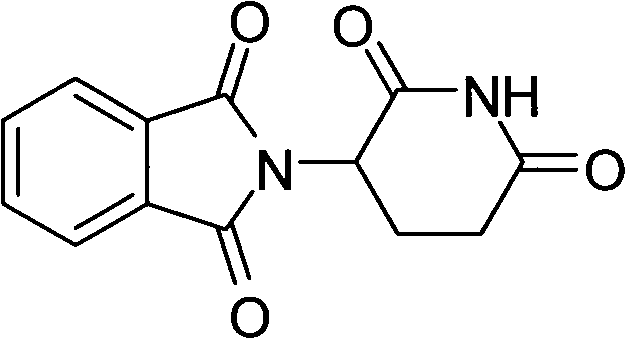

Synthetic method of medicine for treating leprosy

A technology for treating drugs and leprosy, which is applied in the field of medicine, and can solve problems such as long process routes, heavy environmental pollution, and low yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

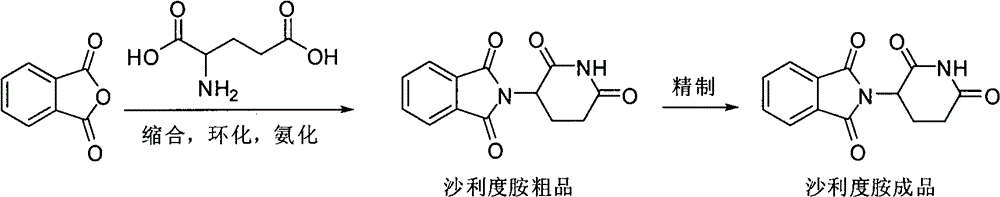

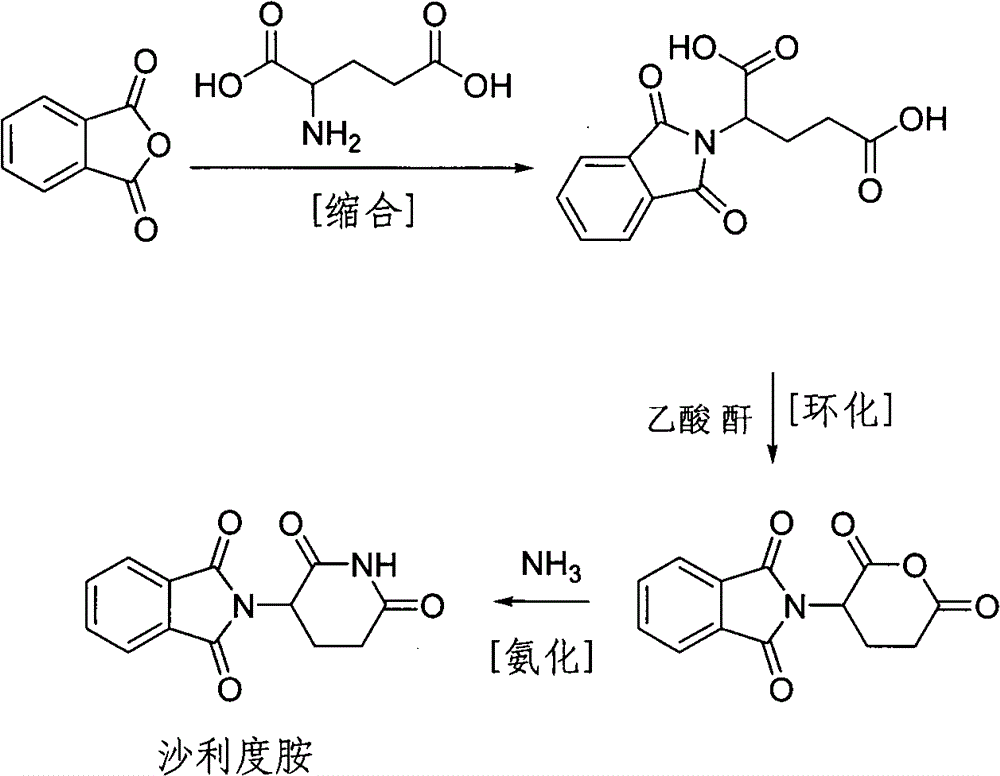

Method used

Image

Examples

Embodiment 1

[0018] Pump 100kg of N, N-dimethylformamide into the reactor, add 50kg of glutamic acid and 50kg of phthalic anhydride under stirring, then heat, react at 95-100°C for 3 hours, and then distill out N , N-dimethylformamide, cooling and adding 100kg of acetic anhydride, heating to 105-110°C for 1 hour reaction, decompressing to remove excess anhydride, heating the reaction to 230°C, slowly feeding ammonia gas under stirring, and reacting After that, discharge the material while it is hot, put it into a reaction pot with 300kg of water in advance, cool to room temperature, and filter to obtain the crude thalidomide, put the crude thalidomide into a tank with 300L dimethyl sulfoxide In the refining pot, add activated carbon, reflux for 1 hour, filter into the crystallization pot, cool to room temperature, filter, and dry to obtain 70.2 kg of thalidomide finished product, with a yield of 80.6%, a melting point of 274-279°C, and a purity of 99.8%. 1 HNMR (DMSO-d 6 ): 11.12(s, 1H), ...

Embodiment 2

[0022] Draw 100kg of N-methylpyrrolidone into the reactor, add 50kg of glutamic acid and 50kg of phthalic anhydride under stirring, then heat, react at 125-130°C for 1 hour, and then distill out N-methylpyrrolidone under reduced pressure , add 100kg of acetic anhydride after cooling, heat to 80-85°C to react for 3 hours, evaporate the excess anhydride under reduced pressure, heat the reaction to 180°C, slowly feed ammonia gas under stirring, and monitor the reaction by thin-layer chromatography. Discharge the material while it is hot, put it into a reaction pot with 300kg of water in advance, cool to room temperature, filter to obtain the crude thalidomide, put the crude thalidomide into the refining pot with 300L dimethyl sulfoxide , add activated carbon, reflux for 1 hour, filter into a crystallization pot, cool to room temperature, filter, and dry to obtain 72.5 kg of thalidomide finished product, with a yield of 83.2%, a melting point of 274-275°C, and a purity of 99.8%.

Embodiment 3

[0024] Pump 100kg of N, N-dimethylformamide into the reactor, add 50kg of glutamic acid and 50kg of phthalic anhydride under stirring, then heat, react at 80-85°C for 5 hours, and then distill out N , N-dimethylformamide, cooling and adding 100kg of acetic anhydride, heating to 115-120 ° C for 1 hour, decompression to remove excess anhydride, heating the reaction to 230 ° C, and slowly feeding ammonia gas under stirring, the reaction After completion, discharge the material while it is hot, put it into a reaction pot with 300kg of water in advance, cool to room temperature, filter to obtain the crude thalidomide, put the crude thalidomide into a refining pot with 300L of isopropanol Inside, add activated carbon, reflux for 1 hour, filter into a crystallization pot, cool to room temperature, filter, and dry to obtain 75.1 kg of thalidomide finished product, with a yield of 86.2%, a melting point of 273-275°C, and a purity of 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com