Preparation method of halogen-free flame-retardant epoxy-resin-modified phenolic FRP material

A technology of epoxy resin and glass fiber reinforced plastics, which is applied in the field of preparation of phenolic glass fiber reinforced plastic materials, can solve the problems of unsatisfactory flame retardancy of phenolic resin materials, and achieve the effect of good strength, excellent flame retardancy and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

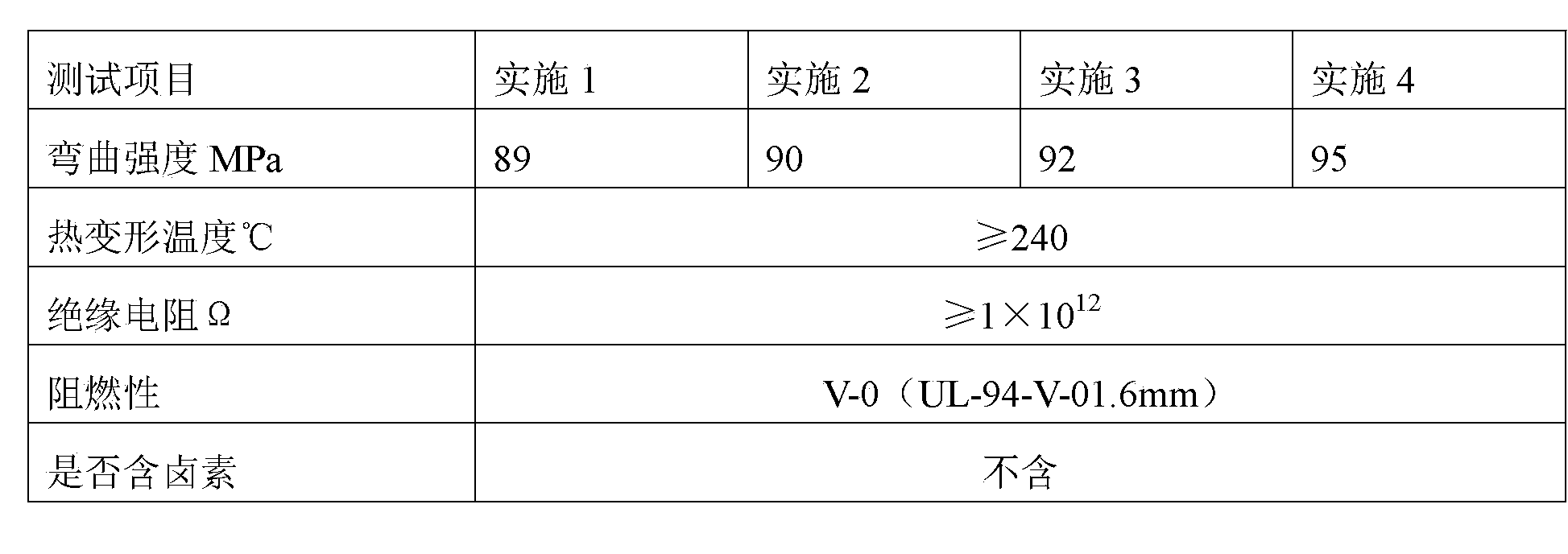

Examples

Embodiment 1

[0016] 72 parts of calcium carbonate taken by weight, 14 parts of silicon dioxide produced by gas phase method, 1.1 parts of N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane and a length of 3mm Put 42 parts of glass fiber into a container with a stirring device and mix well, then put in 76 parts of phenolic resin produced by acid method (hydrochloric acid catalyzed method) and phenolic epoxy resin, that is, phenolic resin and 8 parts of epichlorohydrin condensate, 6 parts of hexamethylenetetramine, 1 part of calcium oxide, 10 parts of polyester epoxy resin, 2.5 parts of zinc stearate and 8 parts of melamine urate, continue to mix Evenly, then transferred to the mill for hot mixing and kneading for 5-6 minutes, finally pulled, cooled and crushed to obtain a halogen-free flame-retardant epoxy resin modified phenolic glass fiber reinforced plastic material.

Embodiment 2

[0018] 76 parts of calcium carbonate taken by weight, 12 parts of silicon dioxide produced by gas phase method, 0.9 part of N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane and a length of 3mm Put 45 parts of glass fiber into a container with a stirring device and mix well, then put in 80 parts of phenolic resin produced by acid method (hydrochloric acid catalyzed method) and phenolic epoxy resin, that is, phenolic resin and Condensate 6 parts of epichlorohydrin, 4 parts of hexamethylenetetramine, 1.8 parts of calcium oxide, 14 parts of polyester epoxy resin, 2.7 parts of zinc stearate and 10 parts of melamine polyphosphate, continue to mix Evenly, then transferred to the mill for hot mixing and kneading for 5-6 minutes, finally pulled, cooled and crushed to obtain a halogen-free flame-retardant epoxy resin modified phenolic glass fiber reinforced plastic material.

Embodiment 3

[0020] 73 parts of calcium carbonate taken by weight, 18 parts of silicon dioxide produced by gas phase method, 1.3 parts of N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane and a length of 3mm Put 43 parts of glass fiber into a container with a stirring device and mix well, then put in 77 parts of phenolic resin produced by acid method (hydrochloric acid catalyzed method) and phenolic epoxy resin, that is, phenolic resin and Condensate 6.5 parts of epichlorohydrin, 5 parts of hexamethylenetetramine, 2 parts of calcium oxide, 11 parts of polyester epoxy resin, 3 parts of zinc stearate and 9 parts of melamine urate, continue to mix Evenly, then transferred to the mill for hot mixing and kneading for 5-6 minutes, finally pulled, cooled and crushed to obtain a halogen-free flame-retardant epoxy resin modified phenolic glass fiber reinforced plastic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com