A temperature-monitoring flame-retardant charging cable

A technology for charging cables and monitoring temperature, which is applied in the direction of power cables, insulated cables, cables with twisted pairs/quads twisted, etc., which can solve problems such as failure to be discovered in time, fire, etc., and improve wear resistance Tear, excellent oil resistance, balance of elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

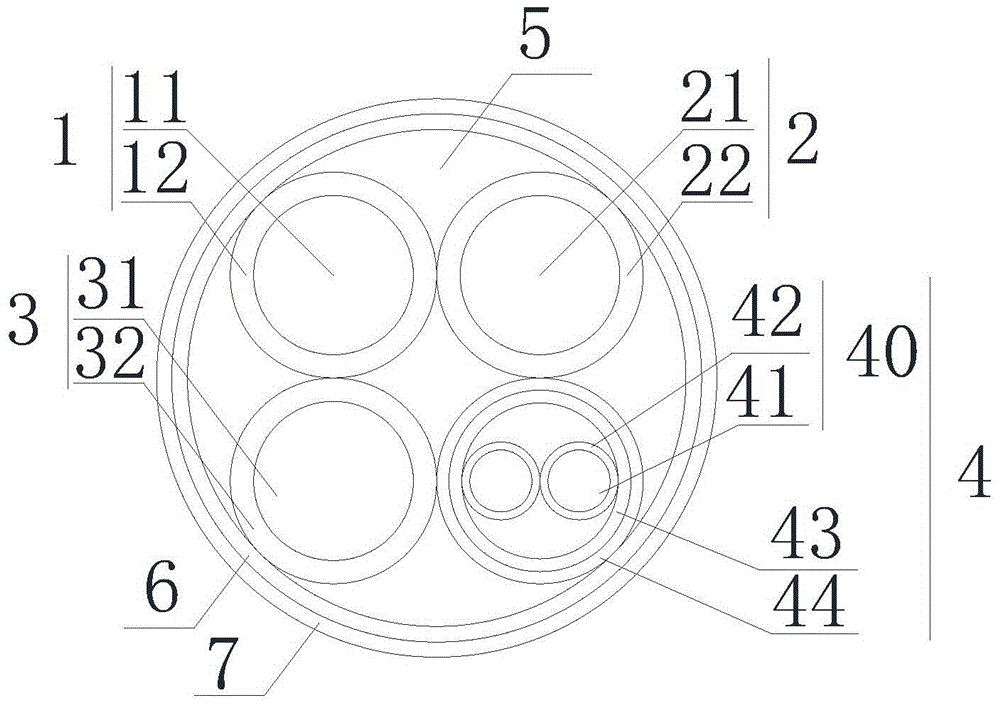

[0027]The first insulating layer 12, the second insulating layer 22, the third insulating layer 32, the fourth insulating layer 42 and the outer sheath 7 in the present invention are all made of low-smoke, halogen-free, flame-retardant, radiation-crosslinked TPE materials, which The raw materials include by weight: 43 parts of styrene-ethylene-propylene-styrene block copolymer SEPS, 45 parts of acrylonitrile-butadiene-styrene copolymer ABS, 10 parts of nanocellulose whiskers, polycarbonate 19 parts of PC, 0.9 parts of titanate coupling agent TMC-201, 34 parts of diatomite, 20 parts of hard clay, 15 parts of high wear-resistant carbon black, 1 part of neodymium oxide, 2 parts of lanthanum oxide, 3 parts of aluminum nitride 6 parts, triphenyl phosphate TPP 6 parts, epoxy cocklebur butyl oleate 6 parts, magnesium hydroxide 5 parts, melamine cyanurate 2 parts, melamine phosphate 2.6 parts, anti-aging agent 2264 1.8 parts, anti-aging agent BLE1 .6 parts, wherein the weight ratio of...

Embodiment 2

[0029] The first insulating layer 12, the second insulating layer 22, the third insulating layer 32, the fourth insulating layer 42 and the outer sheath 7 in the present invention are all made of low-smoke, halogen-free, flame-retardant, radiation-crosslinked TPE materials, which Raw materials include by weight: 45 parts of styrene-ethylene-propylene-styrene block copolymer SEPS, 43 parts of acrylonitrile-butadiene-styrene copolymer ABS, 12 parts of nanocellulose whiskers, polycarbonate 17 parts of PC, 1.2 parts of titanate coupling agent TMC-201, 32 parts of diatomite, 22 parts of hard clay, 13 parts of high wear-resistant carbon black, 1.6 parts of neodymium oxide, 1.3 parts of lanthanum oxide, 3.8 parts of aluminum nitride 4 parts, triphenyl phosphate TPP 4 parts, epoxy cocklebur butyl oleate 8 parts, magnesium hydroxide 3 parts, melamine cyanurate 2.4 parts, melamine phosphate 1.8 parts, anti-aging agent 2264 2.3 parts, anti-aging agent BLE 1.3 servings.

Embodiment 3

[0031] The first insulating layer 12, the second insulating layer 22, the third insulating layer 32, the fourth insulating layer 42 and the outer sheath 7 in the present invention are all made of low-smoke, halogen-free, flame-retardant, radiation-crosslinked TPE materials, which The raw materials include by weight: 44.6 parts of styrene-ethylene-propylene-styrene block copolymer SEPS, 43.7 parts of acrylonitrile-butadiene-styrene copolymer ABS, 11.2 parts of nano-cellulose whiskers, polycarbonate 17.4 parts of PC, 1.1 parts of titanate coupling agent TMC-201, 32.6 parts of diatomite, 21.4 parts of hard clay, 13.5 parts of high wear-resistant carbon black, 1.5 parts of neodymium oxide, 1.4 parts of lanthanum oxide, and 3.7 parts of aluminum nitride 4.5 parts of triphenyl phosphate TPP, 7.8 parts of epoxy butyl oleate, 3.2 parts of magnesium hydroxide, 2.2 parts of melamine cyanurate, 2 parts of melamine phosphate, 2.2 parts of anti-aging agent 2264, anti-aging agent BLE 1.4 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com