Flame-retardant fireproof coiled material and preparation method thereof

A technology of coiled materials and flame-retardant coatings, which is applied in the direction of fire protection, fire-resistant coatings, building components, etc., can solve the problems of large amount of additive flame retardants, reduced flame-retardant durability, and general flame-retardant performance, so as to meet the requirements of industrialization The effect of production requirements, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

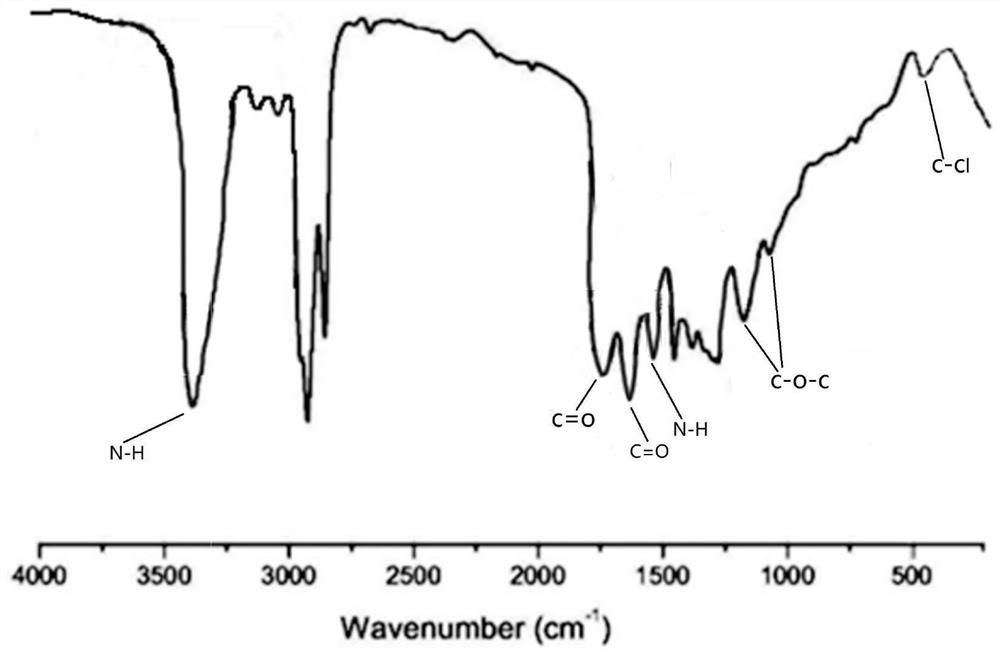

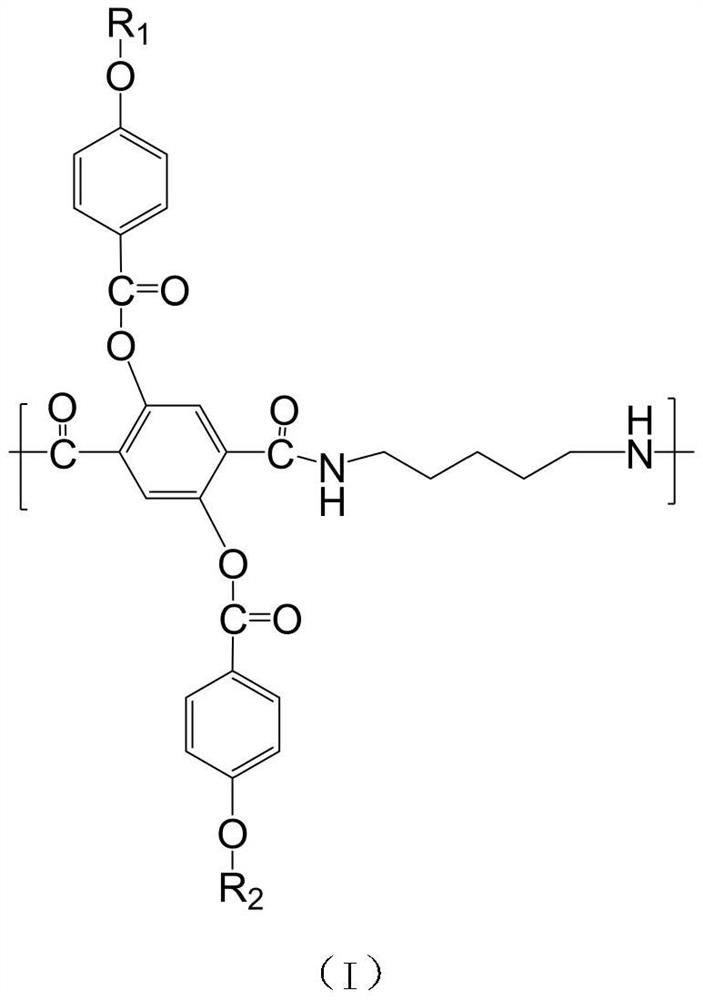

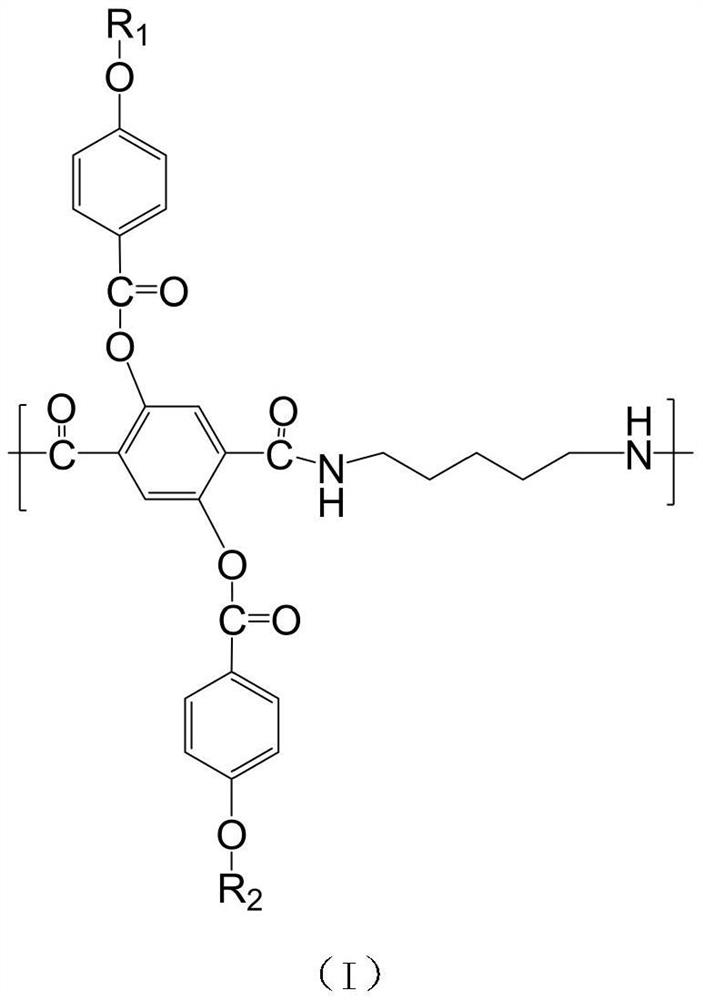

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of carboxyl-containing chlorinated paraffin 42: Dissolve 20 g of chlorinated paraffin 42 in 210 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 28 g of potassium carbonate, and react at 55° C. for 30 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol, and the product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 42.

[0036] (2) Preparation of chlorinated paraffin 42 containing acid chloride: add 70mol carboxyl-containing chlorinated paraffin 42 to the reaction kettle, add dropwise 85mol phosphorus trichloride, stir and heat up to 70°C, react for 4h, cool to room temperature, and stand to separate Layer to obtain chlorinated paraffin 42 containing acid chloride.

[0037] (3) Preparation of chlorinated paraffin 42 modified dibasic acid: add 50mol2,5-dihydroxyterephthalic acid and an appropriate amount of acid-bin...

Embodiment 2

[0041] (1) Preparation of carboxyl-containing chlorinated paraffin 52: Dissolve 20 g of chlorinated paraffin 52 in 220 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 29 g of potassium carbonate, and react at 80° C. for 10 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol. The product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 52.

[0042] (2) Preparation of chlorinated paraffin 52 containing acid chloride: add 70 mol of chlorinated paraffin 52 containing carboxyl to the reaction kettle, dropwise add 85 mol of phosphorus trichloride, stir and heat up to 50°C, react for 6 hours, cool to room temperature, let stand to separate layer to obtain the chlorinated paraffin 52 containing the acid chloride.

[0043] (3) Preparation of chlorinated paraffin 52 modified dibasic acid: add 50mol2,5-dihydroxyterephthalic acid and an appropriate a...

Embodiment 3

[0047] (1) Preparation of carboxyl-containing chlorinated paraffin 70: Dissolve 20 g of chlorinated paraffin 70 in 200 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 30 g of potassium carbonate, and react at 65° C. for 24 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol, and the product was vacuum-dried at 100°C for 5 hours to obtain carboxyl-containing chlorinated paraffin 70.

[0048] (2) Preparation of chlorinated paraffin 70 containing acid chloride: add 70mol carboxyl-containing chlorinated paraffin 70 to the reaction kettle, add dropwise 85mol phosphorus trichloride, stir and heat up to 60°C, react for 5h, cool to room temperature, and stand to separate layer to obtain chlorinated paraffin 70 containing acid chloride.

[0049] (3) Preparation of chlorinated paraffin 70 modified dibasic acid: add 50mol2,5-dihydroxyterephthalic acid and an appropriate amount of acid-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com