Method for preparing double acid etching textures on polycrystalline silicon surface

An acid etching, polysilicon technology, applied in the field of semiconductor optoelectronic materials, can solve the problems of large corrosion amount, different corrosion pit morphology, and solar cell chromatic aberration, etc., to achieve the effect of suitable size, uniform morphology, and ensuring photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

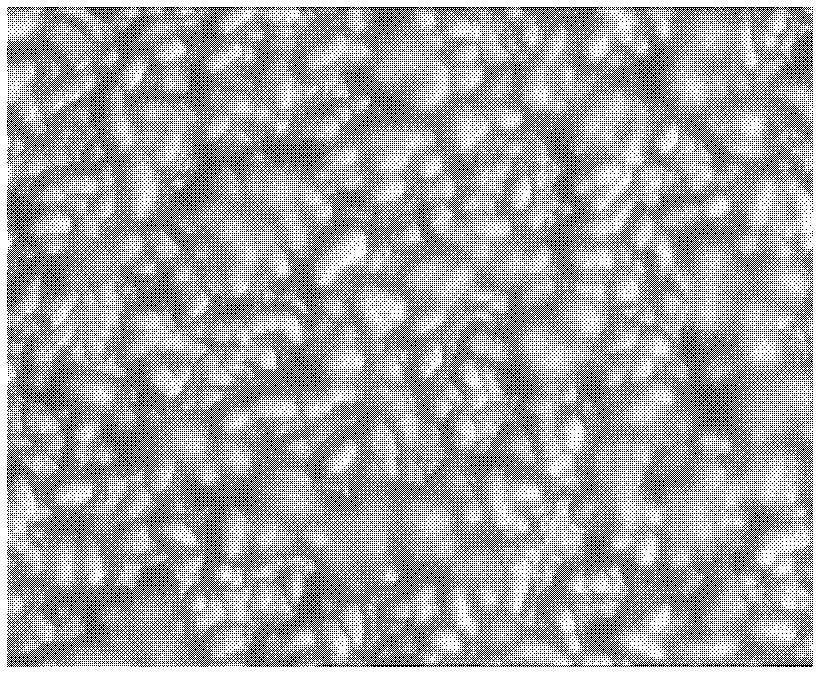

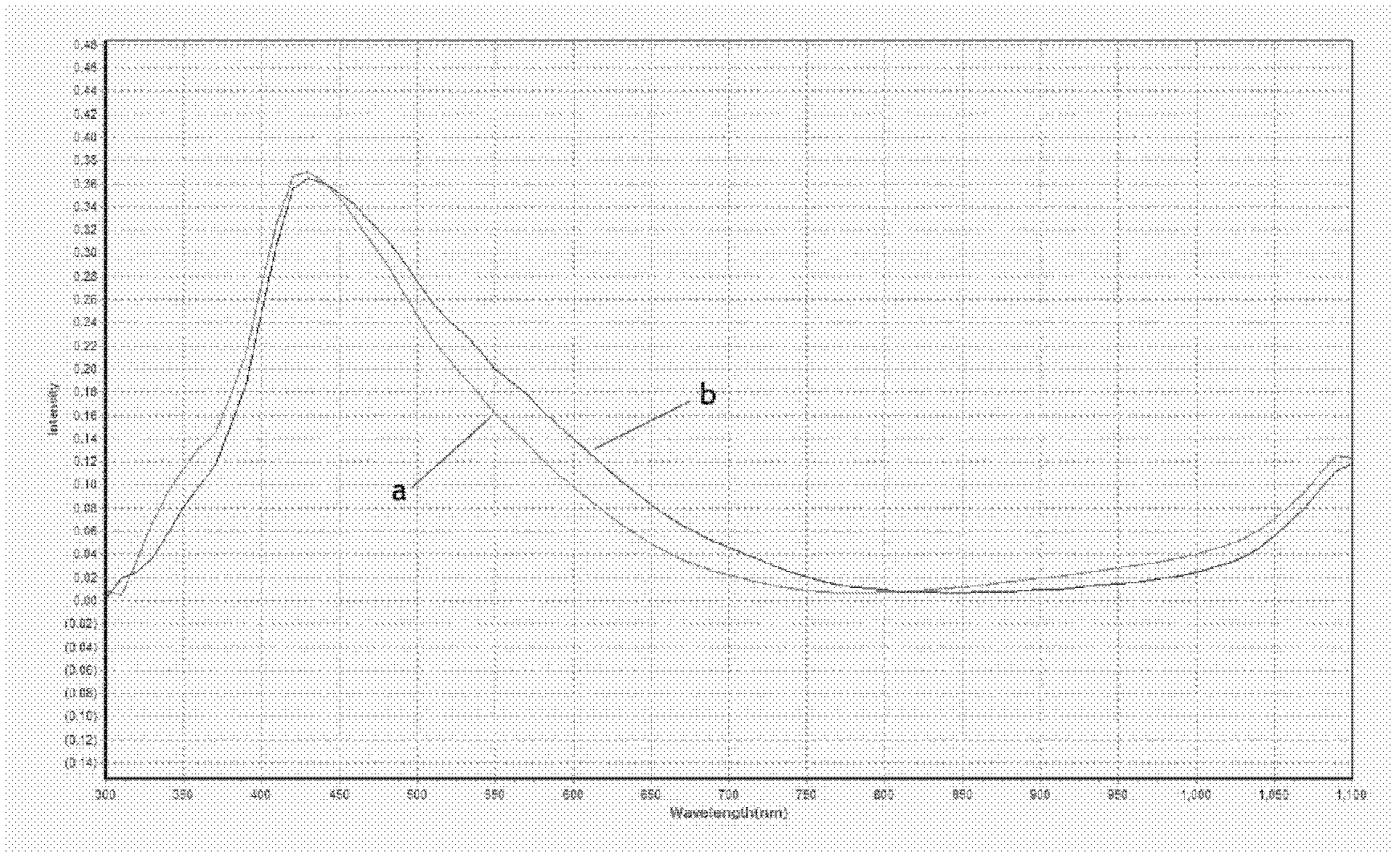

[0013] Example 1: Preparation of HF / HNO 3 The acid solution of the system, adjust the concentration of HF to 3mol / L, HNO 3 The concentration was 9mol / L, the temperature was controlled at 3°C, and the cycle was performed for 2 hours; silicon wafers with different densities of the damaged layer were placed in the solution for 40s, then cleaned with deionized water, placed in 2% NaOH solution for 10s, and then Clean with deionized water; then place in the mixed solution of HF and HCl for 30s, rinse with deionized water and dry; then control the temperature of the acid etching solution at 8°C, put the previously etched silicon wafer into the acid etching The second acid etching texture was carried out in the etching solution, the reaction time was 60s, and then placed in 2% NaOH solution for 10s, and then cleaned with deionized water; then placed in the mixed solution of HF and HCl for 30s, and deionized Rinse with water and blow dry. figure 2 is the corrosion pit on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com