Wind power generation system based on open winding structure and fault tolerance control method thereof

A wind power generation system and fault-tolerant control technology, applied in wind power generation, AC network to reduce harmonics/ripples, harmonic reduction devices, etc., can solve the problems of high cost, difficult control, and difficulty in maintaining normal operation of the control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

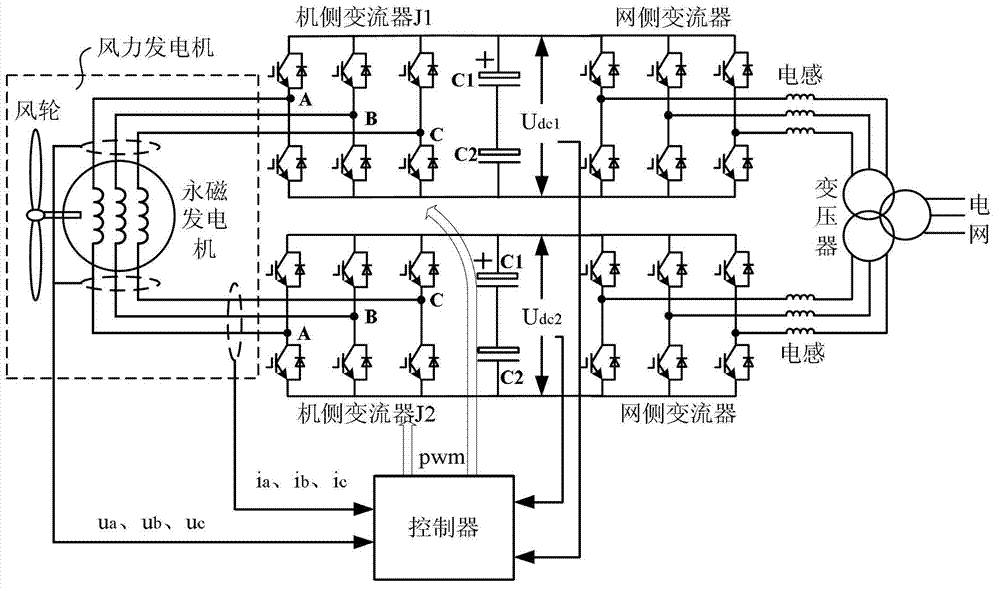

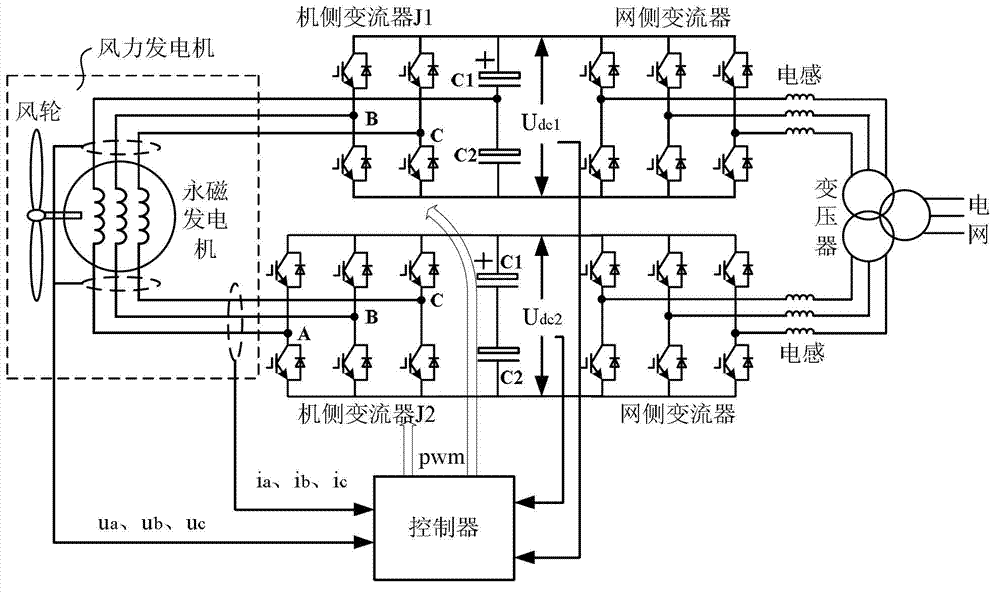

[0054] In order to describe the present invention more specifically, the wind power generation system and its fault-tolerant control method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] Such as figure 2 As shown, a wind power generation system based on an open-winding structure includes: a wind power generator, two machine-side converters, two grid-side converters and a controller;

[0056] The wind power generator includes a wind wheel and a permanent magnet generator. The permanent magnet generator has three-phase windings. The wind wheel drives the rotor of the permanent magnet generator to rotate, thereby converting wind energy into electrical energy.

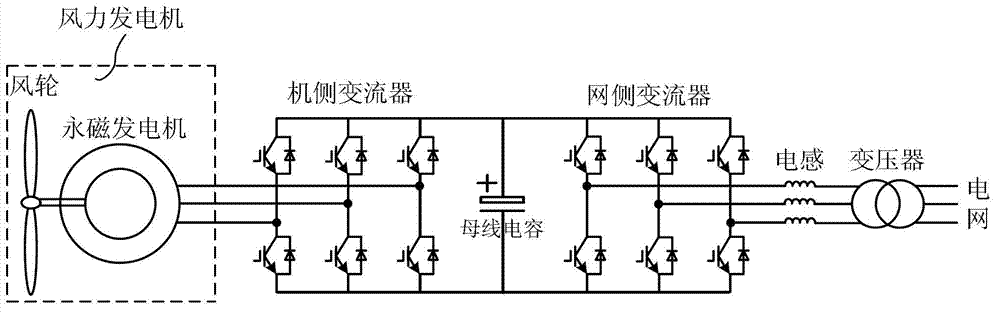

[0057] Both the machine-side converter and the grid-side converter are three-phase six-leg structures, and each bridge arm is composed of an IGBT; the machine-side converter converts the electric energy generated by the wind turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com