Antifoam compositions

A composition and organic technology, applied in the directions of detergent compositions, antifoaming agents, foam regulating compositions, etc., can solve problems such as being difficult to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] Example 1 (invented):

[0153] Mix and homogenize 21 parts of organopolysiloxane B1, 16 parts of organopolysiloxane B2, 3 parts of filler C1, 1 part of filler D1, 1 part of organopolysiloxane resin F1, and 1 part of organopolysiloxane Siloxane G1 and heated at 150° C. for 4 hours in the presence of 1500 ppm KOH. Then add 52 parts of organopolysiloxane A1 and 6 parts of polyether siloxane E1 and mix well.

[0154] The viscosity and defoamer index of the composition are shown in Table 1.

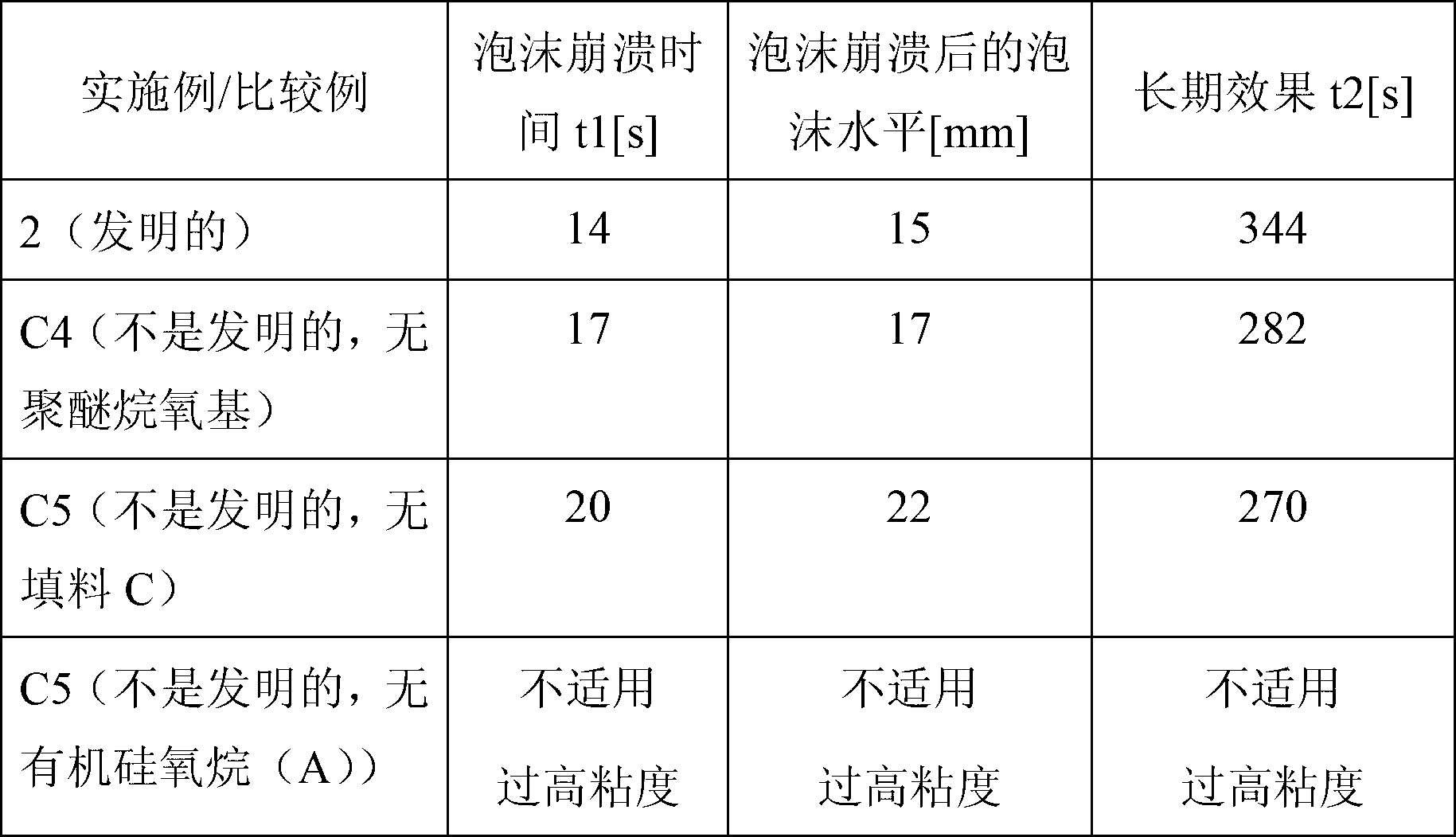

Embodiment 2

[0167] Mix and homogenize 27 parts of organopolysiloxane B2, 2 parts of filler D1, 1 part of organopolysiloxane resin F1, and 1 part of mineral oil H1, and heat at 150°C for 4 Hour. Then add 60 parts of organopolysiloxane A1, 6 parts of filler C2 and 8 parts of polyether silane E1 and mix well.

Embodiment 3

[0180] 100 parts of antifoam formulation from Example 1 at 60°C with 30 parts of sorbitan monostearate (available from Croda GmbH under the name "Span 60" D-Nettetal) and 20 parts of polyoxyethylene (20) Sorbitan monostearate ("Tween 60" from Uniqema D-Emmerich) was mixed and diluted with 500 parts of water. To this mixture was added 2 parts polyacrylic acid (available as "Carbopol 934" from BF Goodrich D-Neuss), followed by mixing and adding a further 345 parts of water and 3 parts of isothiazolinone-based preservative (available from Thor- Chemie, D-Speyer's "Acticide MV"). Subsequently, the emulsion was homogenized at 100 bar using a high-pressure homogenizer, and adjusted to a pH of 6-7 with 10% NaOH.

[0181] The resulting antifoam emulsion is excellent for use in aqueous antifoam surfactant solutions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com