Low-temperature stable mixed-conductor oxygen permeable membrane in perovskite type barium-containing iron series

A technology of mixed conductor and perovskite type, which is applied in the field of mixed conductor oxygen permeable membrane, can solve the problems of membrane permeation flux decline and failure to reach a stable state, and achieve good stability and high oxygen permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

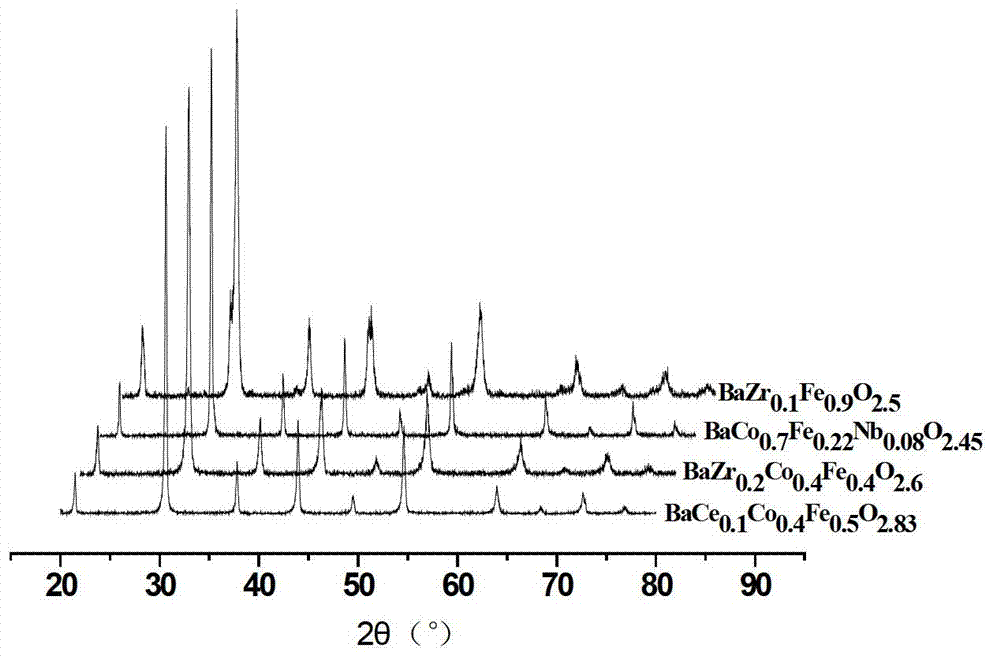

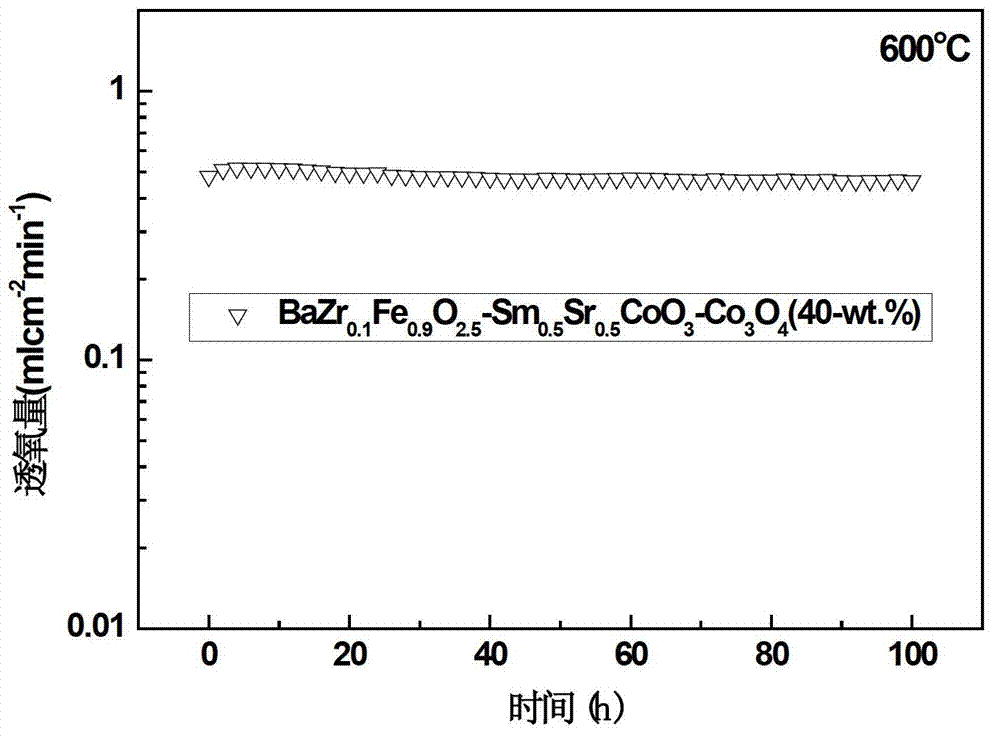

Embodiment 1

[0022] Preparation of Ba by solid-phase synthesis 0.2 Sr 0.8 Fe 0.5 Cu 0.45 Ti 0.05 o 2.3 Powder. The obtained powder was subjected to X-ray diffraction analysis, and the result was a pure perovskite phase. Press the powder into a membrane under a pressure of 200-300MPa and evaluate the oxygen permeability under the condition of 700°C. The thickness of the membrane is 0.5mm, and it is sealed with silver. The air flow rate is 150ml / min, and the helium flow rate is 50ml / min. And apply La evenly on both sides of the diaphragm 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 Catalyst slurry, the oxygen permeability can be maintained at 1.5mlcm within 500 hours -2 min -1 Left and right no attenuation was seen.

Embodiment 2

[0024] Preparation of Ba by solid-phase synthesis 0.95 Gd 0.05 Fe 0.7 Cr 0.25 Mo 0.05 o 2.9Powder. The obtained powder was subjected to X-ray diffraction analysis, and the result was a pure perovskite phase. Press the powder into a membrane under a pressure of 200-300MPa to evaluate the oxygen permeability at 675°C. The thickness of the membrane is 0.5mm, and evenly coat both sides of the membrane with Pr 2 o 3 Catalyst slurry, sealed with silver, air flow rate: 150ml / min, helium flow rate: 50ml / min. Oxygen permeability has not declined within 200 hours and is stable at 0.8mlcm -2 min -1 about.

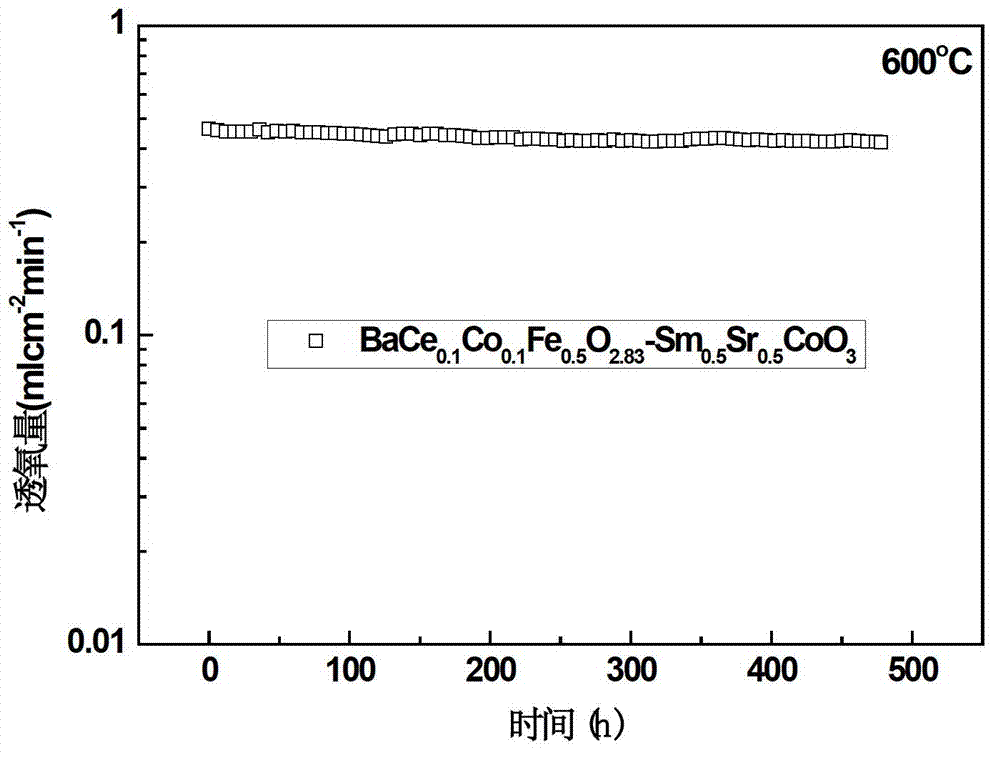

Embodiment 3

[0026] Preparation of La by solid-phase synthesis 0.3 Sr 0.3 Ba 0.4 Fe 0.9 mn 0.1 o 2.35 Powder. The obtained powder was subjected to X-ray diffraction analysis, and the result was a pure perovskite phase. Press the powder into a membrane under a pressure of 200-300MPa to evaluate the oxygen permeability at 650°C. The thickness of the membrane is 0.5mm, and the two sides of the membrane are evenly coated with La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 -Co 3 o 4 (40-wt.%) catalyst paste was sealed with silver. The air flow rate is 150ml / min, and the helium flow rate is 50ml / min. Tested under the condition of 650°C, the oxygen transmission rate has not decayed within 300 hours and is stable at 0.5mlcm -2 min -1 about.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com