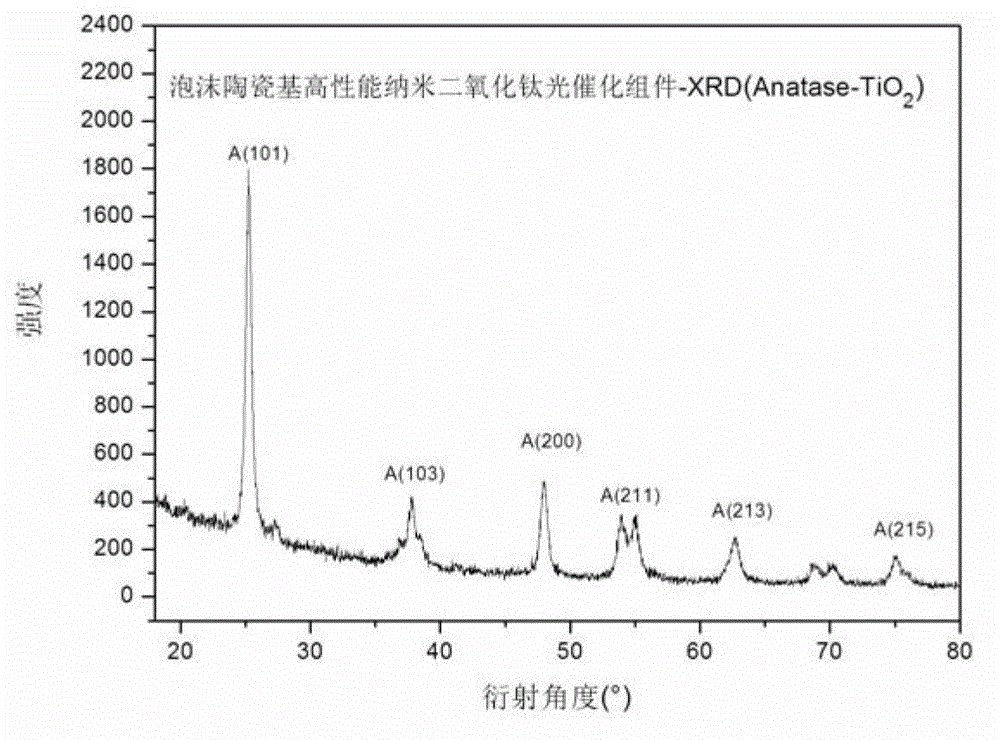

Foamed ceramic based photocatalytic component and preparation method thereof

A technology of foam ceramics and photocatalysis, applied in chemical instruments and methods, separation methods, catalyst carriers, etc., to achieve good permeability, contact promotion, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

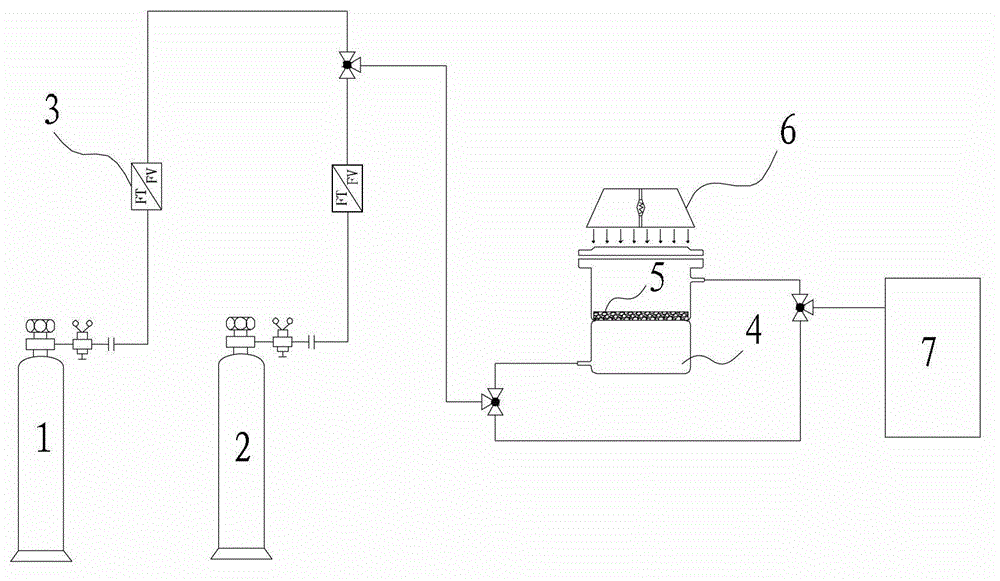

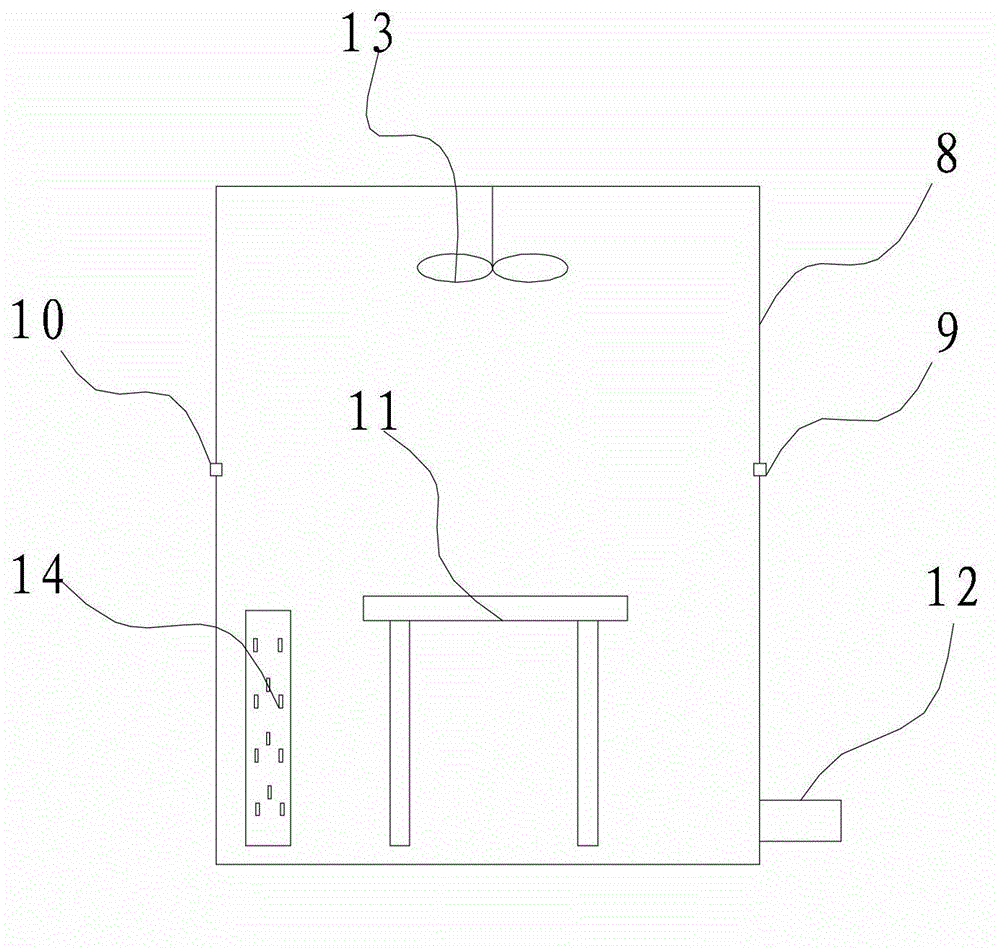

Method used

Image

Examples

Embodiment 1

[0037] 1). The SiC foam ceramics (with a porosity of 75%) were ultrasonically cleaned with acetone for 20 minutes, then deionized water for 20 minutes, and finally dried at 60° C. for use.

[0038] 2). Mix and stir 35ml tetrabutyl titanate, 40ml absolute ethanol, and 40ml glacial acetic acid for 30 minutes, then add a mixed solution of 5.4ml deionized water and 40ml absolute ethanol, and stir for 1 hour to obtain a stable, uniform and transparent TiO 2 Sol.

[0039] 3). Add commercial degussa P25 and polyethylene glycol 400, the amount of P25 added is TiO in the sol 2 content of 45%, the addition of polyethylene glycol 400 is TiO 2 8% of the content.

[0040] 4). Immerse the ceramic foam in 1) completely in the sol, take it out after ultrasonication for 10 minutes, and dry it at 80°C. This step is repeated 3 times.

[0041] 5). Put the ceramic foam in 4) in a muffle furnace, burn it at 450°C for 2 hours, and take it out after the muffle furnace cools down to below 60°C.

...

Embodiment 2

[0045] 1). Al 2 o 3 The foamed ceramics (with a porosity of 75%) were ultrasonically cleaned with acetone for 20 minutes, then deionized water for 20 minutes, and finally dried at 60° C. for use.

[0046] 2). Mix and stir 35ml tetrabutyl titanate, 40ml absolute ethanol, and 40ml glacial acetic acid for 30 minutes, then add a mixed solution of 5.4ml deionized water and 40ml absolute ethanol, and stir for 1 hour to obtain a stable, uniform and transparent TiO 2 Sol.

[0047] 3). Add commercial Degussa P25 and polyethylene glycol 400, the amount of P25 added is TiO in the sol 2 content of 20%, the addition of polyethylene glycol 400 is TiO 2 5% of the content.

[0048] 4). Immerse the ceramic foam in 1) completely in the sol, take it out after ultrasonication for 10 minutes, and dry it at 80°C. This step is repeated once.

[0049] 5). Put the ceramic foam in 4) in a muffle furnace, burn it at 300°C for 2 hours, and take it out after the muffle furnace cools down to below 60°...

Embodiment 3

[0052] 1). Al 2 o 3 The foamed ceramics (with a porosity of 75%) were ultrasonically cleaned with acetone for 20 minutes, then deionized water for 20 minutes, and finally dried at 60° C. for use.

[0053] 2). Mix and stir 20ml tetrabutyl titanate, 30ml absolute ethanol, and 20ml glacial acetic acid for 30 minutes, then add a mixed solution of 10ml deionized water and 40ml absolute ethanol, and stir for 1 hour to obtain a stable, uniform and transparent TiO 2 Sol.

[0054] 3). Add commercial Degussa P25 and polyethylene glycol 400, the amount of P25 added is TiO in the sol 2 content of 40%, the addition of polyethylene glycol 400 is TiO 2 15% of the content.

[0055] 4). Immerse the ceramic foam in 1) completely in the sol, take it out after ultrasonication for 10 minutes, and dry it at 80°C. This step is repeated 5 times.

[0056] 5). Put the ceramic foam in 4) in a muffle furnace, burn it at 400°C for 2 hours, and take it out after the muffle furnace cools down to below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com