Resin gel waste core sand reproduction line

A production line and resin technology, applied in casting molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. environment and other problems, to achieve the effect of uniform particles, good quality and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

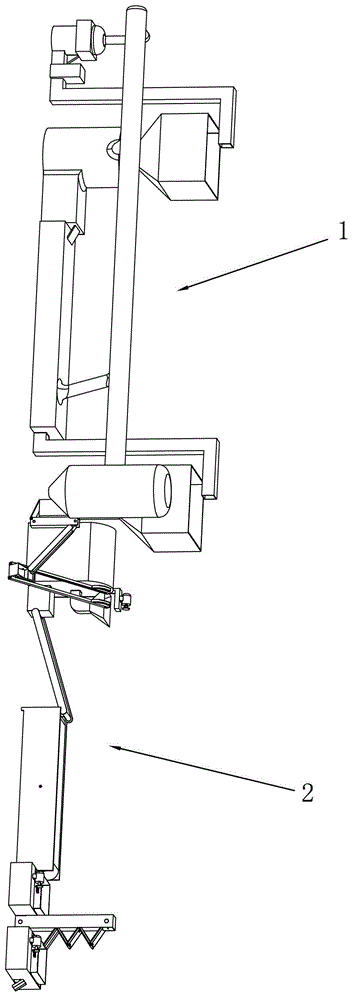

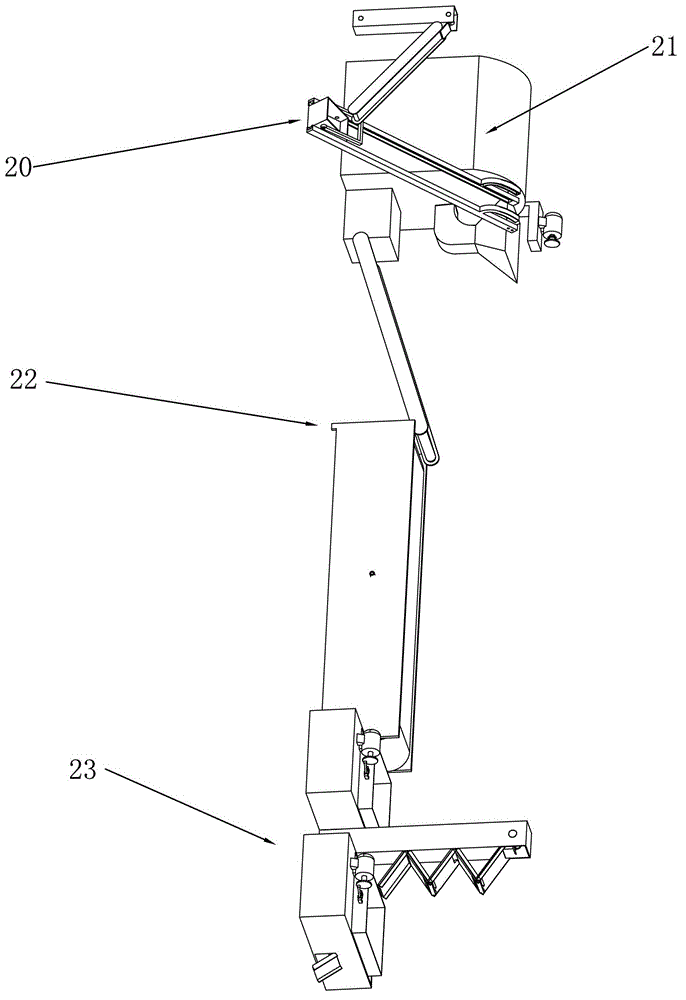

[0028] Such as Figure 1-Figure 7 As shown, a resin cored sand waste sand regeneration production line disclosed in the present invention includes coated sand regeneration equipment 1 and resin cored sand processing equipment 2 .

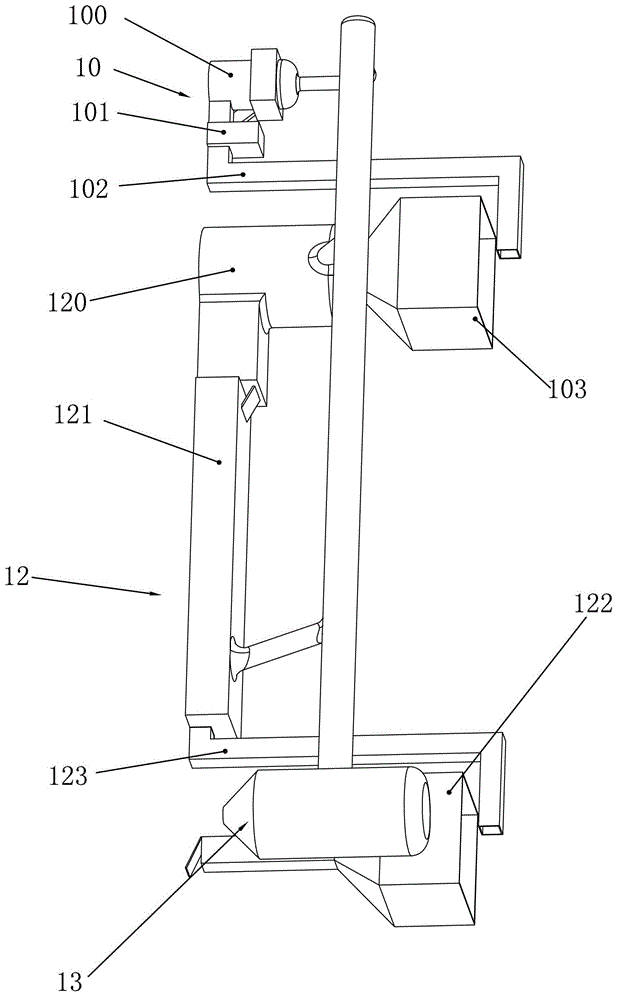

[0029]In this embodiment, the coated sand regeneration equipment 1 includes a pretreatment system 10, a thermal regeneration device 12, a dust removal system 13 and an electric control system; the electric control system is connected with the pretreatment system 10, the thermal regeneration device 12, Dust removal system 13 is connected. The pretreatment system 10 includes a crushing and screening machine 100 and a magnetic separator 101 which are connected in sequence; Bin 122; a regenerated sand elevator 123 (bucket elevator) is set between the regenerated coated sand storage bin 122 and the cooling bed 121 to realize material transfer; a waste sand elevator is arranged between the magnetic separator 101 and the feeder 102 (for the bucket elevat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com