Radius highly synchronous and precise broaching processing method for double bearing bushes and automation device

An automatic device and radius height technology, which is applied in broaching devices, positioning devices, metal processing, etc., can solve the problems of small processing range, low processing accuracy, and difficulty in ensuring the accuracy of two bearing bushes, so as to reduce labor intensity, Improve work efficiency and enhance safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

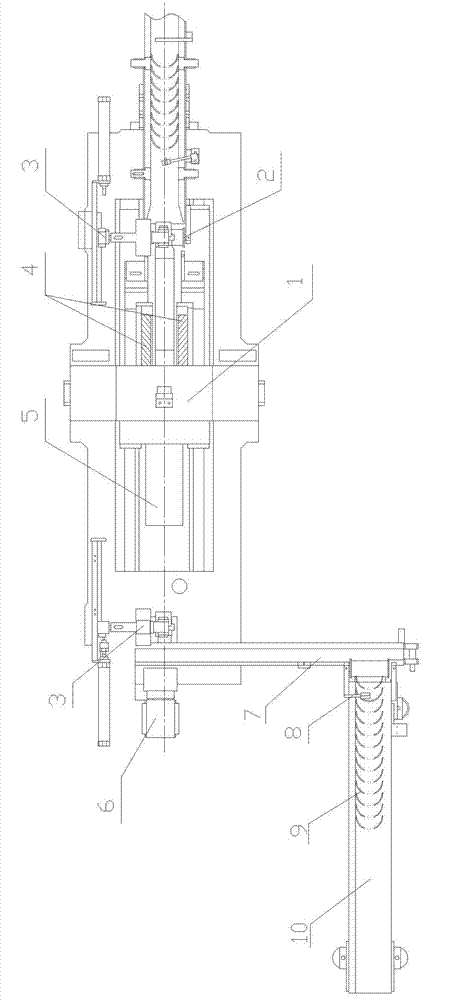

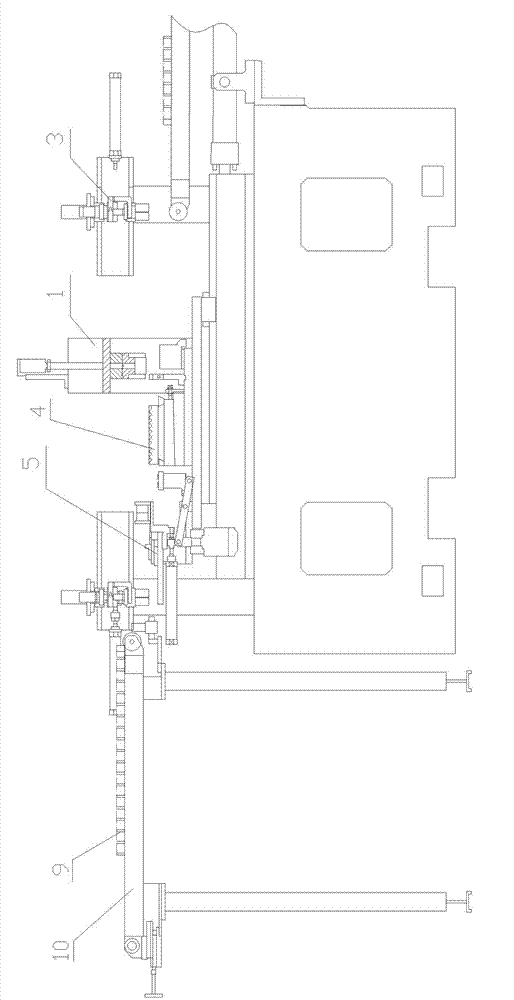

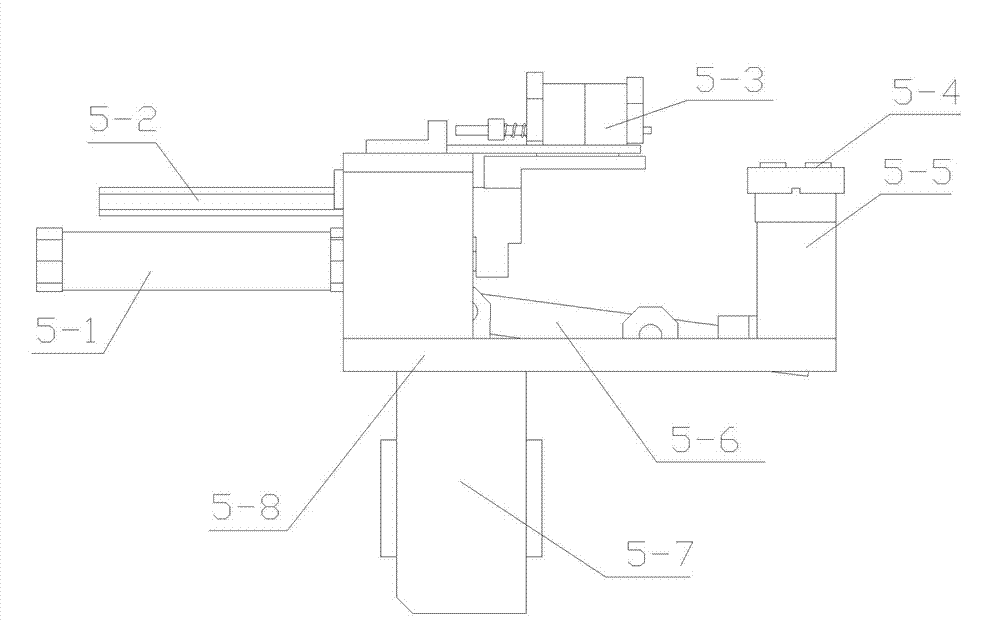

[0021] The invention provides a processing method of double-piece bearing bush radius high synchronous precision broaching and an automatic device based on the method. The processing method includes the automatic feeding and feeding of the bearing bush, the clamping positioning and the broaching process. The key improvement lies in the addition of a double-piece bearing bush floating preset positioning process before the clamping and positioning process. The specific processing steps are:

[0022] ①With the help of the multi-channel damping device set on the conveyor belt, the bearing bushes in transmission are transported to the loading station in two groups according to the rhythm of the broaching process, and then the double-piece bearing bushes are sent to the support by means of the manipulator and the feeding drive mechanism. On the support plate 5-4 with spring expansion on the end face of the four-piece mouth of the double-piece bearing bush; when the radius and height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com