Method for radially rolling and forming ring piece with three steps and complicated section

A ring and step technology, which is applied in the field of ring rolling and forming, can solve the problems of low production efficiency, large machining allowance, and high labor intensity, and achieve the effects of reducing equipment requirements, smooth processing process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

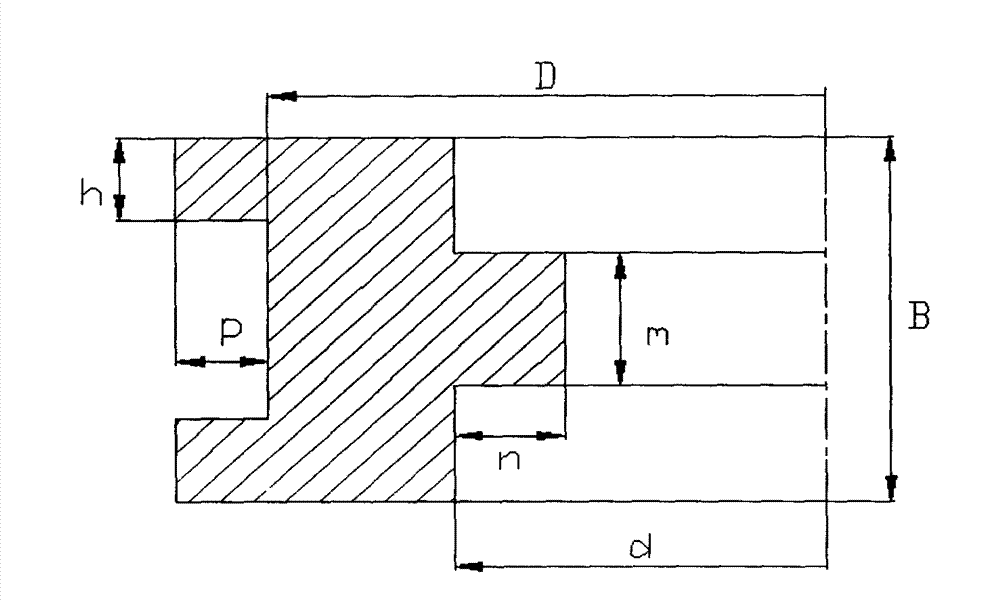

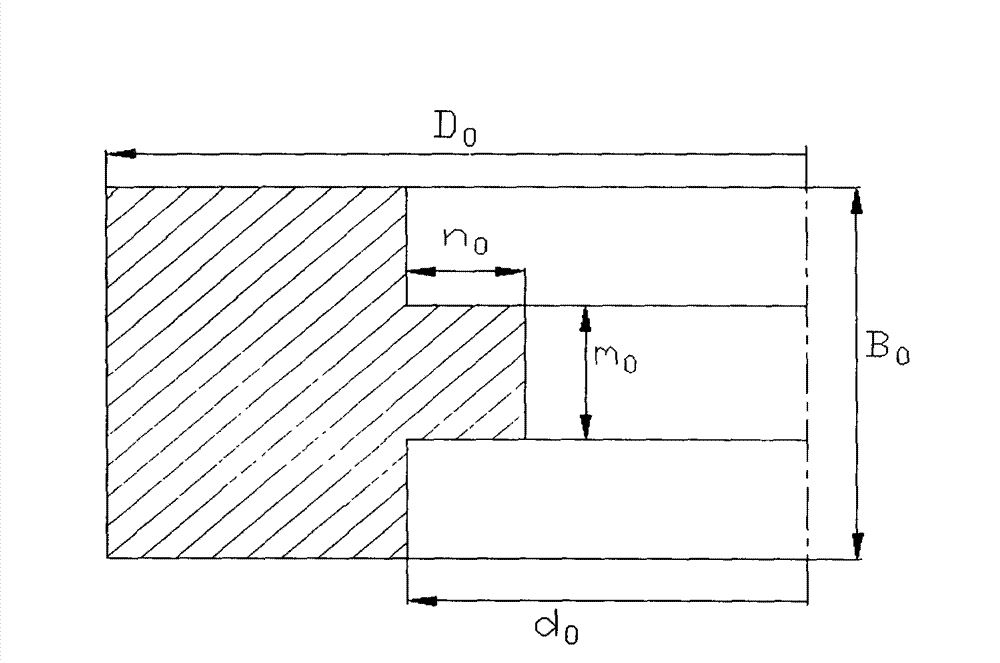

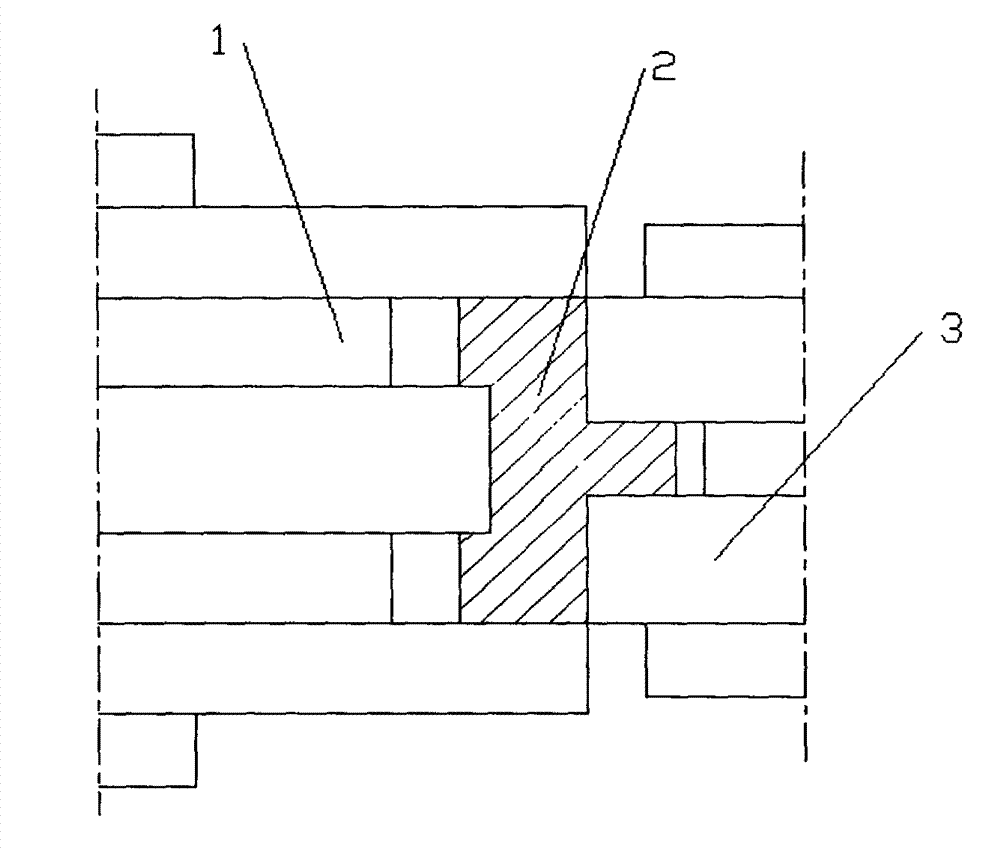

[0032] A radial rolling forming method for rings with three steps of complex cross-section. The material of the rings is Q345E steel. The size of the ring forgings required to be rolled is: The diameter d of the inner hole of the ring forging is The axial height B of the ring forging is 400mm, the axial dimension m of the inner control step of the ring forging is 200mm, the radial dimension n of the inner hole step of the ring forging is 150mm, the axial dimension h of the outer step of the ring forging is 50mm, and the ring forging The radial dimension p of the outer step of the forging is 80mm. The steps are as follows:

[0033] (1) Saw the cylindrical Q345E bar into material sections, the length of the material section is L=3B=1200mm, B is the axial dimension of the ring forging, and the diameter of the material section is determined according to the condition that the volume of the ring forging is equal to the volume of the material section. 1050mm.

[0034] (2) Slowl...

Embodiment 2

[0040] A radial rolling forming method for rings with three steps of complex cross-section. The material of the rings is Q345E steel. The size of the ring forgings required to be rolled is: The diameter d of the inner hole of the ring forging is The axial height B of the ring forging is 300mm, the axial dimension m of the inner hole step of the ring forging is 100mm, the radial dimension n of the inner hole step of the ring forging is 60mm, and the axial dimension h of the outer step of the ring forging is 50mm. The radial dimension p of the outer step of the forging is 60mm. The steps are as follows:

[0041] (1) Cut the cylindrical Q345E bar into material section, the length of the material section is L=4B=1200mm, B is the axial dimension of the ring forging, and the diameter of the material section is determined according to the condition that the volume of the ring forging is equal to the volume of the material section. 650mm.

[0042] (2) Slowly heat the material sec...

Embodiment 3

[0047] A radial rolling forming method for rings with three steps of complex cross-section. The material of the rings is Q345E steel. The size of the ring forgings required to be rolled is: The diameter d of the inner hole of the ring forging is The axial height B of the ring forging is 100mm, the axial dimension m of the inner hole step of the ring forging is 50mm, the radial dimension n of the inner hole step of the ring forging is 30mm, and the axial dimension h of the outer step of the ring forging is 25mm. The radial dimension p of the outer step of the forging is 20mm. The steps are as follows:

[0048] (1) Saw the cylindrical Q345E bar into material sections, the length of the material section is L=3.5B=350mm, B is the axial dimension of the ring forging, and the diameter of the material section is determined according to the condition that the volume of the ring forging is equal to the volume of the material section is 380mm.

[0049] (2) Slowly heat the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com