Method for massively preparing high-quality graphene

A large-scale preparation and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of poor mechanical properties and electrical conductivity, complex technical process, inability to completely remove oxygen-containing functional groups, etc., to achieve small thickness and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

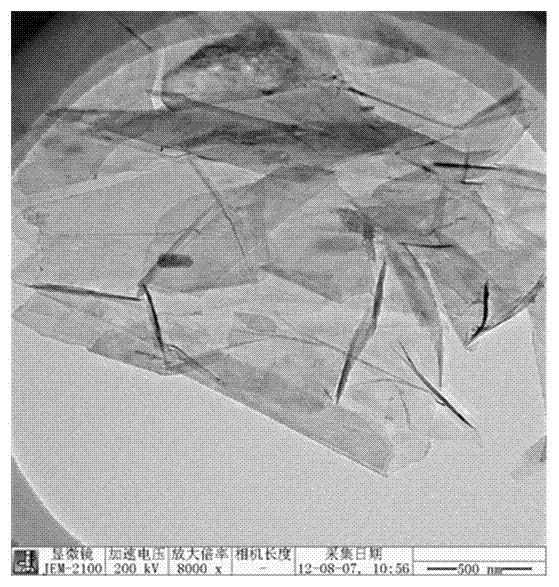

[0023] Prepare 200ml of 10wt% azodicarbonamide hot water solution, disperse 5g of expanded graphite in the above solution, stir and immerse for 150 minutes and ultrasonicate for 5 minutes to remove unreacted expanded graphite, wash and dry to obtain graphene, the average thickness of the sheet 0.98nm, oxygen content 2.13% (mass fraction).

Embodiment 2

[0025] Prepare 200ml of 15wt% azobisisobutyronitrile ethanol solution, disperse 8g of expanded graphite in the above solution, stir and immerse for 180 minutes, ultrasonic for 30 minutes, remove unreacted expanded graphite, wash and dry to obtain graphene, sheet The average thickness is 0.75nm, and the oxygen content is 2.81% (mass fraction).

Embodiment 3

[0027] Prepare 200ml of azobisisoheptanonitrile methanol solution of 12wt%, disperse 6g of expanded graphite in the above solution, stir and immerse for 600 minutes and ultrasonic for 60 minutes, remove unreacted expanded graphite, wash and dry to obtain graphene, and the sheets are averaged The thickness is 0.82 nm, and the oxygen content is 2.63% (mass fraction).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com