Polycrystalline-silicon reducing and producing process and device

A production process, polysilicon technology, applied in the direction of silicon, etc., can solve the problems that the energy consumption of the reduction furnace is difficult to achieve the expected effect, and the heat energy of the polysilicon reduction furnace is not fully utilized, etc., and achieve high conversion rate, low energy consumption and high deposition speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

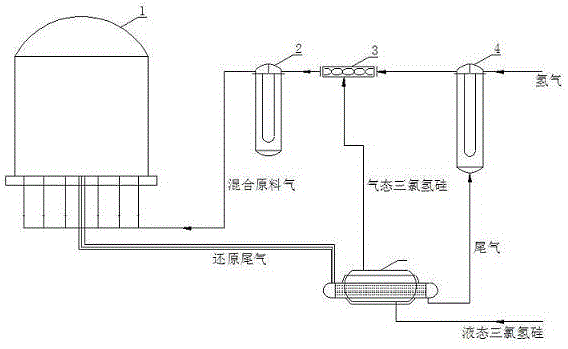

[0027] Such as figure 1 As shown, the polysilicon reduction production device described in the embodiment of the present invention includes a trichlorosilane vaporizer 5, a hydrogen preheater 4, a static mixer 3, a constant temperature heat exchanger 2 and a reduction furnace 1, and the trichlorosilane The gaseous trichlorosilane outlet of the vaporizer 5 and the hot hydrogen outlet of the hydrogen preheater 4 are respectively connected to the static mixer 3, and the pipeline between the mixed gas outlet of the static mixer 3 and the reduction furnace 1 is provided with the Constant temperature heat exchanger 2.

[0028] Further, the tail gas outlet of the reduction furnace 1 is communicated with the tube-side inlet of the trichlorosilane vaporizer 5, and the reduction tail gas is used as a heat source of the trichlorosilane vaporizer 5, and the tube-side outlet of the trichlorosilane vaporizer 5 is Connected to the hydrogen preheater 4, the reduction tail gas is used as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com