Preparation method of cross-linked amphoteric bagasse xylan

A technology of xylan and bagasse, applied in the field of preparation of cross-linked amphoteric bagasse xylan, achieving high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

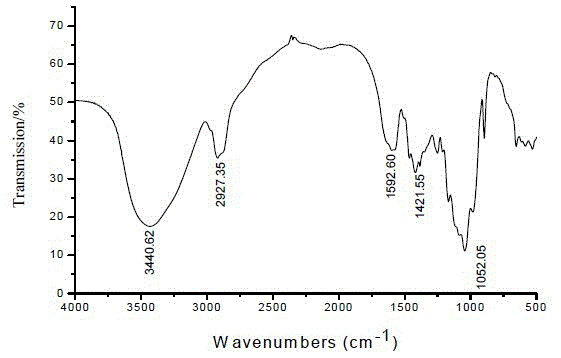

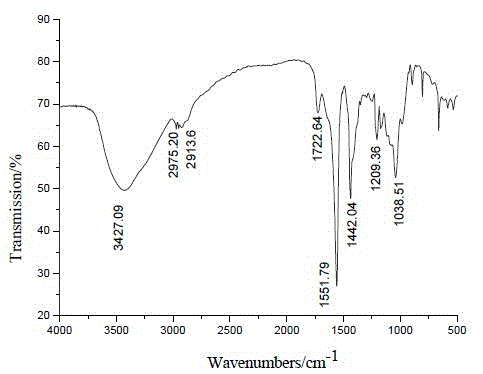

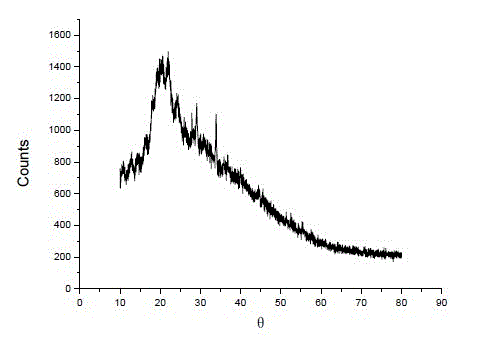

Image

Examples

Embodiment 1

[0046] (1) Dry bagasse xylan in a vacuum oven at 60°C to constant weight to obtain powdery dry basis bagasse xylan.

[0047] (2) Weigh 12 g of powdery dry-based bagasse xylan and 25 g of deionized water obtained in step (1) into the reactor, stir and mix at room temperature to obtain a xylan suspension with a mass fraction of 32.43%.

[0048] (3) Weigh 0.9g of sodium hydroxide and dissolve it in 6.0mL of deionized water, add it to the xylan suspension obtained in step (2); adjust the pH of the system to 9 with a concentration of 3.0mol / L hydrochloric acid, stir and activate for 1.5 hours .

[0049] (4) Dissolve 1.2g of esterifying agent succinic anhydride in 20mL of ethanol with a volume fraction of 95% to obtain succinic anhydride ethanol solution;

[0050] (5) Weigh 0.1g catalyst 12-tungstophosphoric acid into the system obtained in step (3), control the reaction temperature at 40±2°C, and add the succinic anhydride ethanol solution obtained in step (4) into step (3) in thr...

Embodiment 2

[0060] (1) Dry bagasse xylan in a vacuum oven at 60°C to constant weight to obtain powdery dry basis bagasse xylan.

[0061] (2) Weigh 15 g of powdery dry-based bagasse xylan and 28 g of deionized water obtained in step (1) into the reactor, stir and mix at room temperature to obtain a xylan suspension with a mass fraction of 34.88%.

[0062] (3) Dissolve 1.2g of sodium hydroxide in 15mL of deionized water and add it to the xylan suspension obtained in step (2); adjust the pH of the system to 10 with 3.0mol / L hydrochloric acid, and stir for 1.5 hours to activate.

[0063] (4) Dissolve 2.0 g of esterifying agent succinic anhydride in 40 mL of ethanol with a volume fraction of 95% to obtain succinic anhydride ethanol solution.

[0064] (5) Weigh 0.3g catalyst 12-tungstophosphoric acid into the system obtained in step (3), control the reaction temperature at 60±2°C, add the succinic anhydride ethanol solution obtained in step (4) into step (3) in three batches at intervals of 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com