High stability methanol gasoline and preparation method thereof

A methanol gasoline and high-stability technology is applied in the field of high-stability methanol gasoline and its preparation, and achieves the effects of low price, high stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

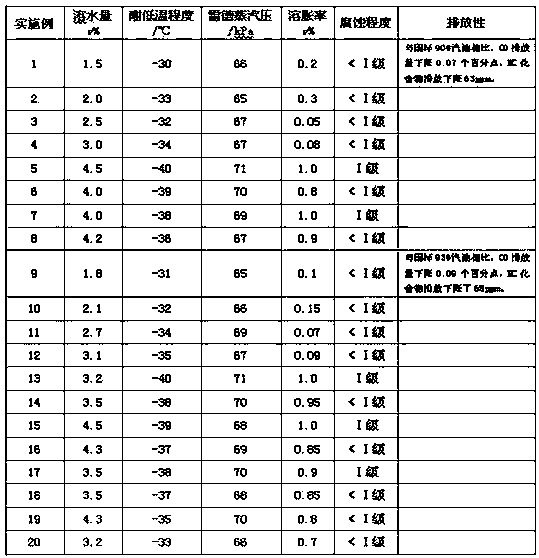

Examples

Embodiment 1

[0064] A kind of high-stability methanol gasoline, which is prepared by mixing the following raw materials in volume percentage:

[0065] National standard 90# motor gasoline 40%

[0066] Industrial Methanol 41.5%

[0067] Phase stabilizer 15%

[0068] Vapor pressure regulator 3%

[0069] Anti-corrosion anti-swelling agent 0.5%.

[0070] The 15% phase stabilizer consists of: 5% methyl tert-butyl ether, 5% ethylene glycol butyl ether, 3% n-butanol, 2% MOA-3, and the vapor pressure regulator is dimethyl carbonate , the anti-corrosion and anti-swelling agent is benzotriazole. The above are volume percentages, and the same will not be described below.

[0071] The preparation method of this embodiment is as follows: at normal temperature and pressure, first add industrial methanol in proportion to the blending tank filled with national standard 90# motor gasoline, and then add phase stabilizer, vapor pressure regulator and Anti-corrosion and anti-swelling agent, after the ad...

Embodiment 2

[0074] The raw material composition volume ratio of this embodiment is the same as that of Example 1, and the difference is that: the 15% phase stabilizer consists of: 5% methyl tert-butyl ether, 5% ethylene glycol butyl ether, 3% normal Octanol, 2%MOA-3B, the vapor pressure regulator is diisopropyl ether, and the anti-corrosion and anti-swelling agent is n-butylamine.

[0075] The preparation method of this embodiment is the same as that of Example 1.

[0076] The methanol gasoline of this embodiment has high stability, its water solubility is 2.0%, its low temperature resistance is -33°C, its saturated vapor pressure is 65kPa, its swelling rate is 0.3%, and its corrosion degree of copper sheet is less than grade I, which effectively solves the problem of existing alcohol oil fuel. outstanding issues. The methanol gasoline of this embodiment has strong power, low fuel consumption, high efficiency and cleanliness, and low preparation cost, can be directly used by motor vehicl...

Embodiment 3

[0078] A kind of high-stability methanol gasoline, which is prepared by mixing the following raw materials in volume percentage:

[0079] National standard 90# motor gasoline 62.7%

[0080] Industrial Methanol 25%

[0081] Phase stabilizer 10%

[0082] Vapor pressure regulator 2%

[0083] Anti-corrosion anti-swelling agent 0.3%.

[0084] The 10% phase stabilizer consists of: 2% methyl tert-butyl ether, 2% ethylene glycol butyl ether, 5% n-butanol, 1% MOA-3; the vapor pressure regulator is dimethyl carbonate , the anti-corrosion and anti-swelling agent is benzotriazole.

[0085] The preparation method of this embodiment is as follows: at normal temperature and pressure, first add industrial methanol in proportion to the blending tank filled with national standard 90# motor gasoline, and then add phase stabilizer, vapor pressure regulator and Anti-corrosion and anti-swelling agent, after the addition is completed, use the pump to circulate, stir for 15 minutes, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com