Heat treatment method of novel alloy steel hollow car axle material

A heat treatment method and technology for hollow axles, which are applied in heat treatment equipment, quenching agents, manufacturing tools, etc., can solve the problem of not providing the heat treatment technology for manufacturing axles, and achieve the effect of excellent low temperature impact toughness and wide allowable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention provides a heat treatment method for a novel alloy steel hollow axle material. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] A series of novel alloy steel hollow axle materials are processed by the method of the present invention, and the specific methods are shown in Table 1.

[0017] Table 1 heat treatment parameter table

[0018]

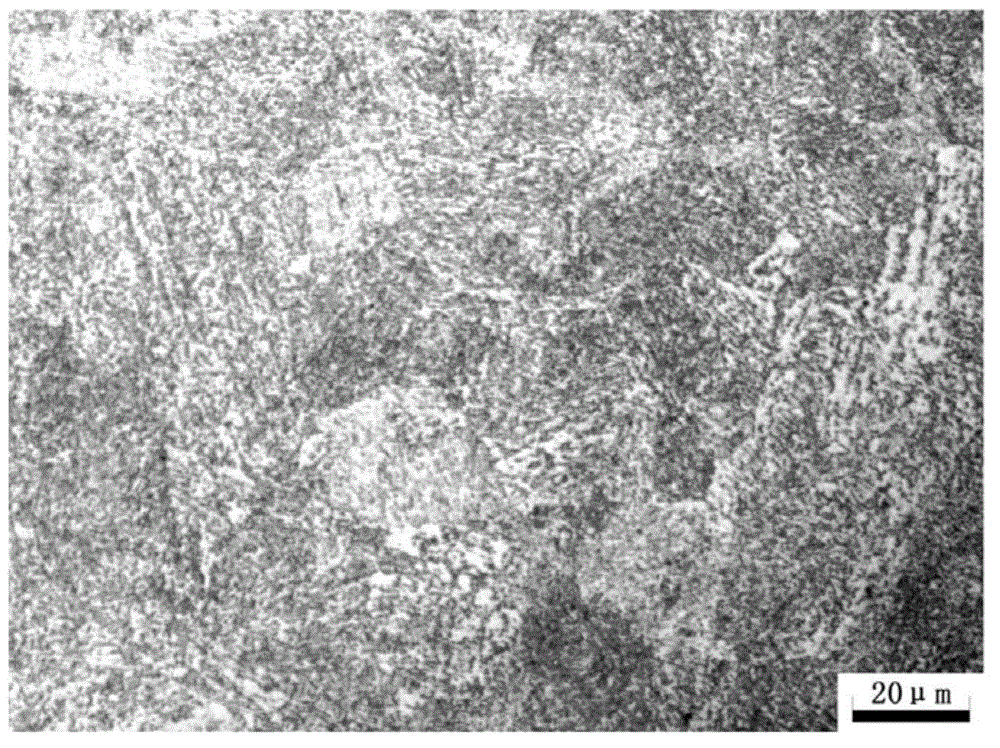

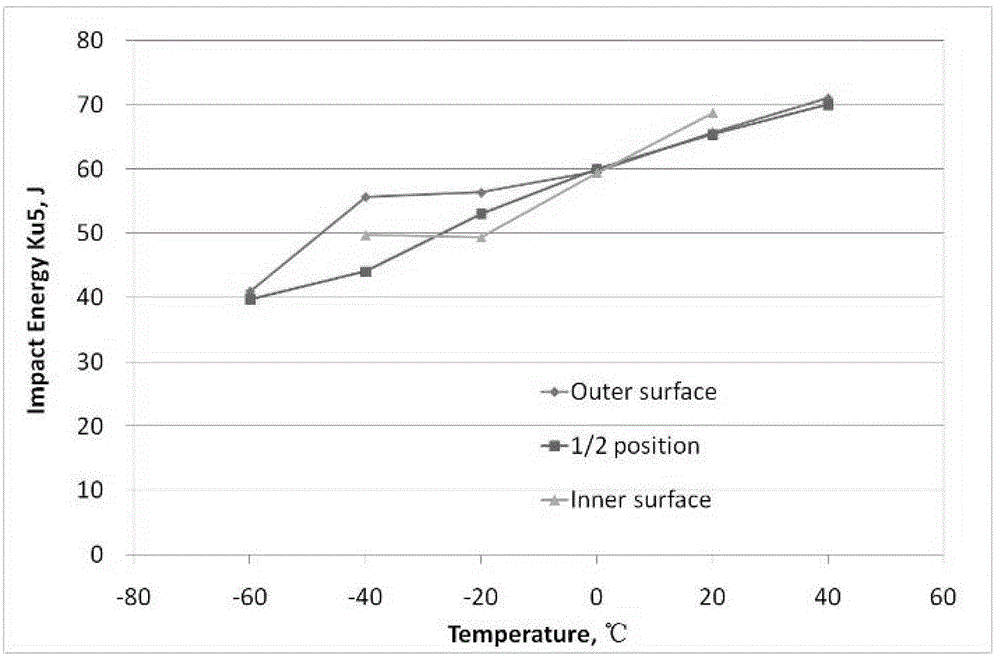

[0019] The method of the present invention is easy to control and is suitable for industrialized production. The grain size of the new alloy steel hollow axle blank after the above heat treatment process is 8-9 grades, and the microstructure at 1 / 2 of the radius of the axle body can be seen figure 1 ; Its strength, plasticity, toughness and fatigue properties are shown in Table 2, all of which exceed the requirements of the European high-speed hollow axle standard EN13261. In the case of increased strength, the plasticity still...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com