Coating method of two-component polyurethane synthetic leather and coating machine special for two-component polyurethane synthetic leather

A two-component polyurethane and coating method technology, which is applied to chemical instruments and methods, devices for coating liquid on the surface, coatings, etc., can solve the problems of fast adhesion, production failure, etc., and increase production capacity , prevent loss, reduce energy consumption and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

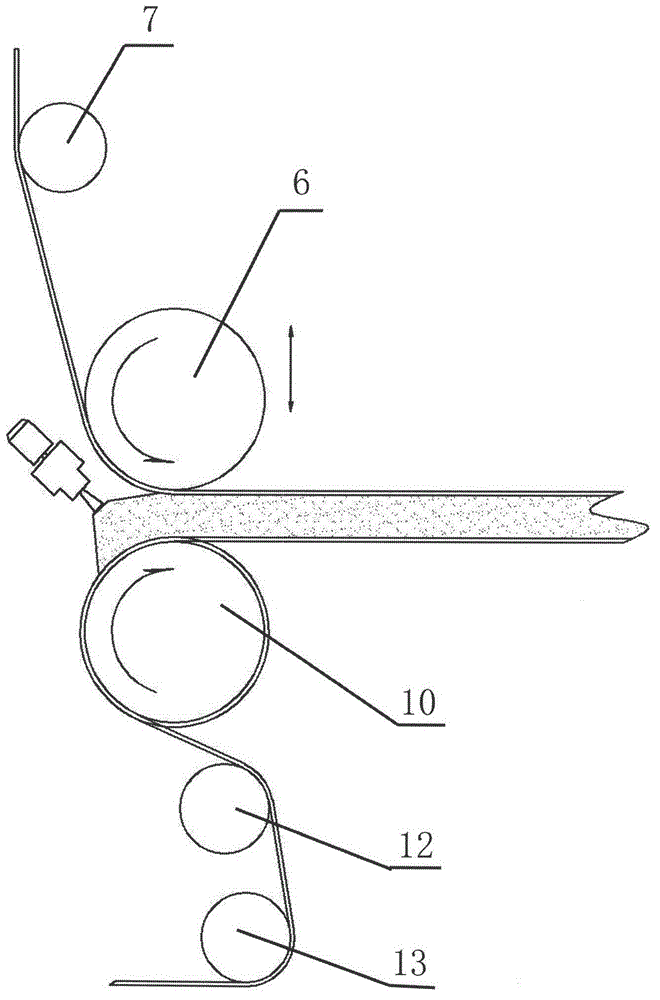

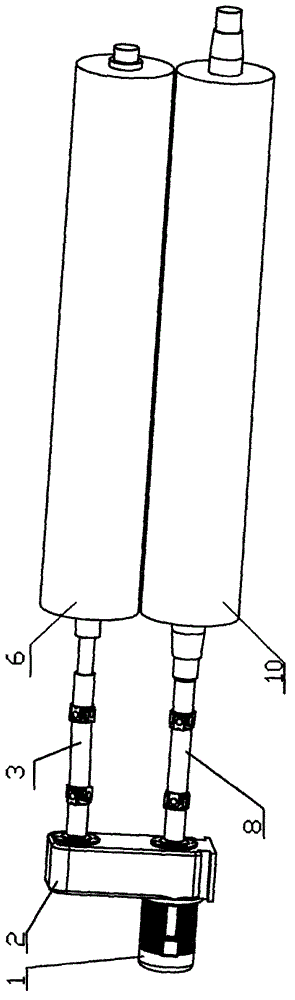

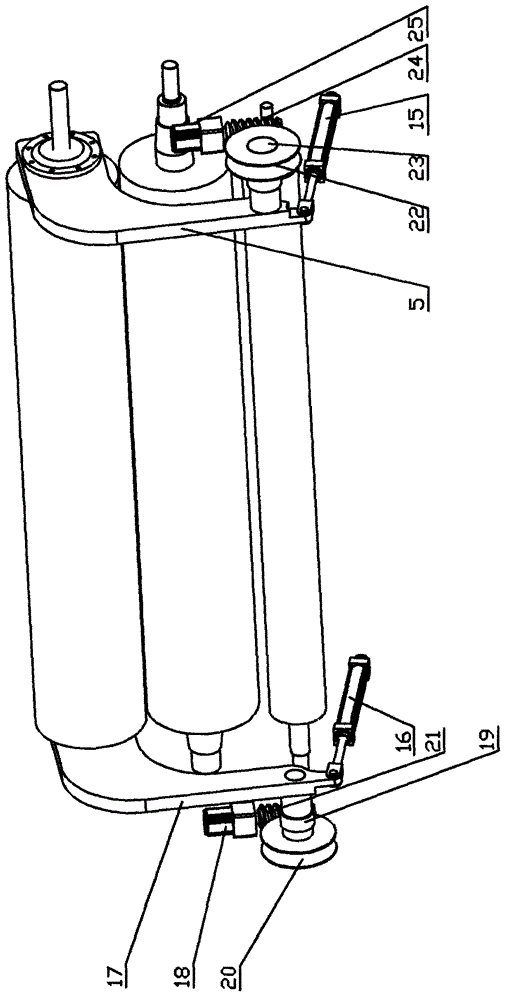

[0036] Embodiment 1: as figure 1 , figure 2 , image 3 , as shown in Figure 4, the special coating machine for two-component polyurethane synthetic leather consists of a frame 14, a substrate guide roller 7, an upper release paper guide roller 12, a lower release paper guide roller 13, an upper coating roller 6, Lower coating roller 10, motor 1, transfer case 2, upper coating roller transmission shaft 3, lower coating roller transmission shaft 8, left two-component polyurethane coating thickness adjustment arm 5, upper left coating roller opening cylinder 15, Left two-component polyurethane coating thickness adjustment motor 25, left two-component polyurethane coating thickness adjustment worm 24, left two-component polyurethane coating thickness adjustment worm wheel 22, right two-component polyurethane coating thickness adjustment arm 17, upper right gap Roller opening cylinder 16, right two-component polyurethane coating thickness adjustment motor 18, right two-component...

Embodiment 2

[0042] Embodiment 2: The difference between the two-component polyurethane synthetic leather coating machine provided in this embodiment and the embodiment 1 is that a release paper pallet 9 is added, so that the two-component polyurethane mixture is sprinkled on the attached release paper A controllable leveling time of the two-component polyurethane mixture is obtained on the surface layer of the paper, and then it is scraped by the upper coating roller 6 and the lower coating roller 10 to obtain a high-quality two-component polyurethane with uniform thickness, firm adhesion and soft hand feeling. Polyurethane synthetic leather.

[0043] Such as Figure 5 , Image 6 , Figure 7 , as shown in Figure 8, the two-component polyurethane synthetic leather special coating machine includes a motor 1, a transfer case 2, an upper coating roller transmission shaft 3, a bearing shaft seat 4, a left two-component polyurethane coating thickness adjustment arm 5, Upper coating roller 6,...

Embodiment 3

[0050] Embodiment 3: the difference between the two-component polyurethane synthetic leather special coating machine provided in this embodiment and embodiment 1 is that a pair of coating rollers, the upper coating roller 6 is a powerless roller, and the lower coating roller 10 Rotate under the drive of motor 1; the upper coating roller 6 is pulled by the winding machine I31, such as Figure 9 As shown, the winder I31 and the winder II32 are synchronized. Under the action of the base cloth and the upper coating roller wrapping angle, the upper coating roller 6 rotates accordingly, and the lower coating roller 10 rotates under the drive of the motor 1 to make the release paper (surface layer) moves forward with the substrate, such as Figure 10 As shown, the two-component polyurethane is sprinkled on the release paper (surface layer) at the front end of the upper and lower coating rollers, and is extruded evenly through the gap between the upper and lower coating rollers as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com