Carbon dioxide cyclic injection system of coal-bed gas well

A technology for carbon dioxide and coalbed methane wells, applied in wellbore/well components, production fluid, measurement, etc., can solve the problems of bulky equipment, achieve the effects of reducing recovery cycle, improving recovery rate and economic benefits, and reducing gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

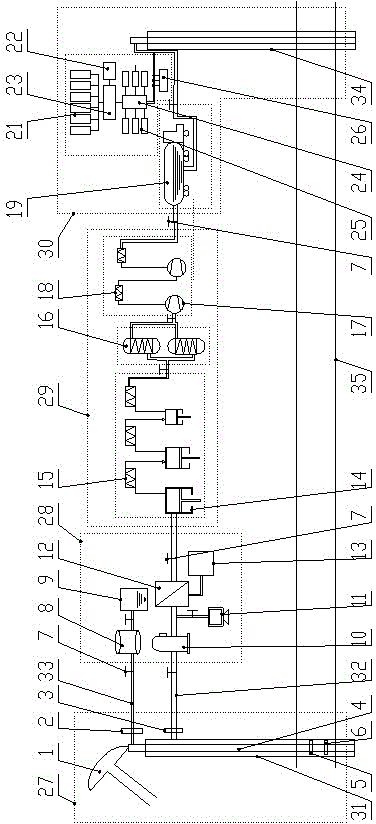

[0035] like figure 1 As shown, the CBM well circulating carbon dioxide injection system of the present invention includes an intelligent extraction part 27 , a gas separation part 28 , a carbon dioxide compression dehydration condensation part 29 and a carbon dioxide injection power part 30 connected in sequence.

[0036] The intelligent drainage part includes an intelligent extraction machine 1, a downhole pressure gauge 6, a downhole thermometer 5, a gas flowmeter 3 and a water flowmeter 2. The downhole pressure gauge 6 and the downhole thermometer 5 are respectively installed at the bottom of the coalbed methane production well 31. The sucker rod 4 of the intelligent extraction machine 1 is placed at 5-10m above and below the coal seam section of the coalbed methane production well 31 (in the early stage of drainage, it is placed at 0-5m above the coal seam, and after the first workover, it can be placed 0-10m below the coal seam section), the upper end of the coalbed metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com