Device capable of changing straight reciprocating movement to continuous circular movement

A technology of linear reciprocating motion and circular motion, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of difficult manufacturing and high cost, and achieve the effects of reduced cost, reduced loss and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0023] The invention includes a reciprocating rack and a gear meshed with the rack.

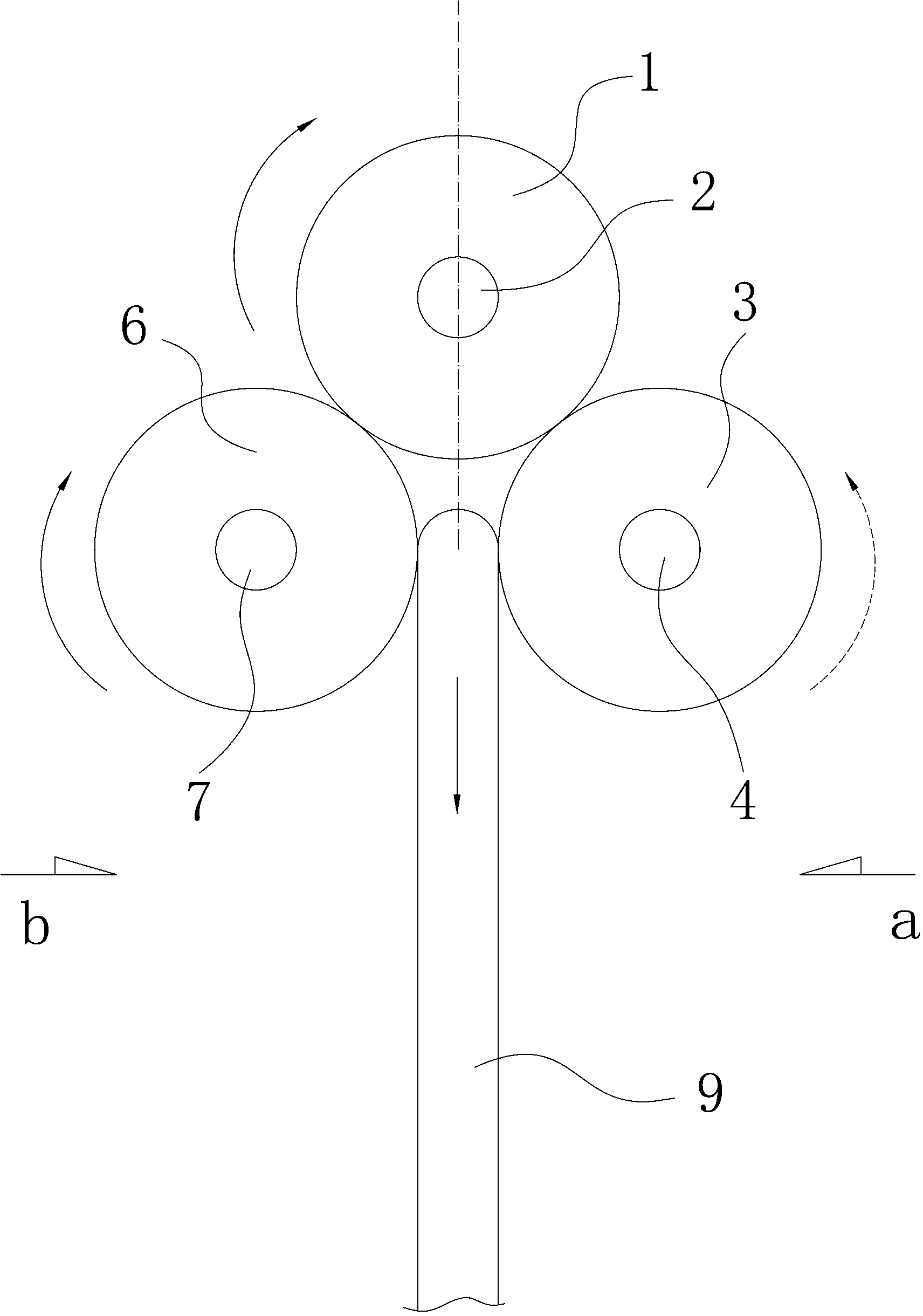

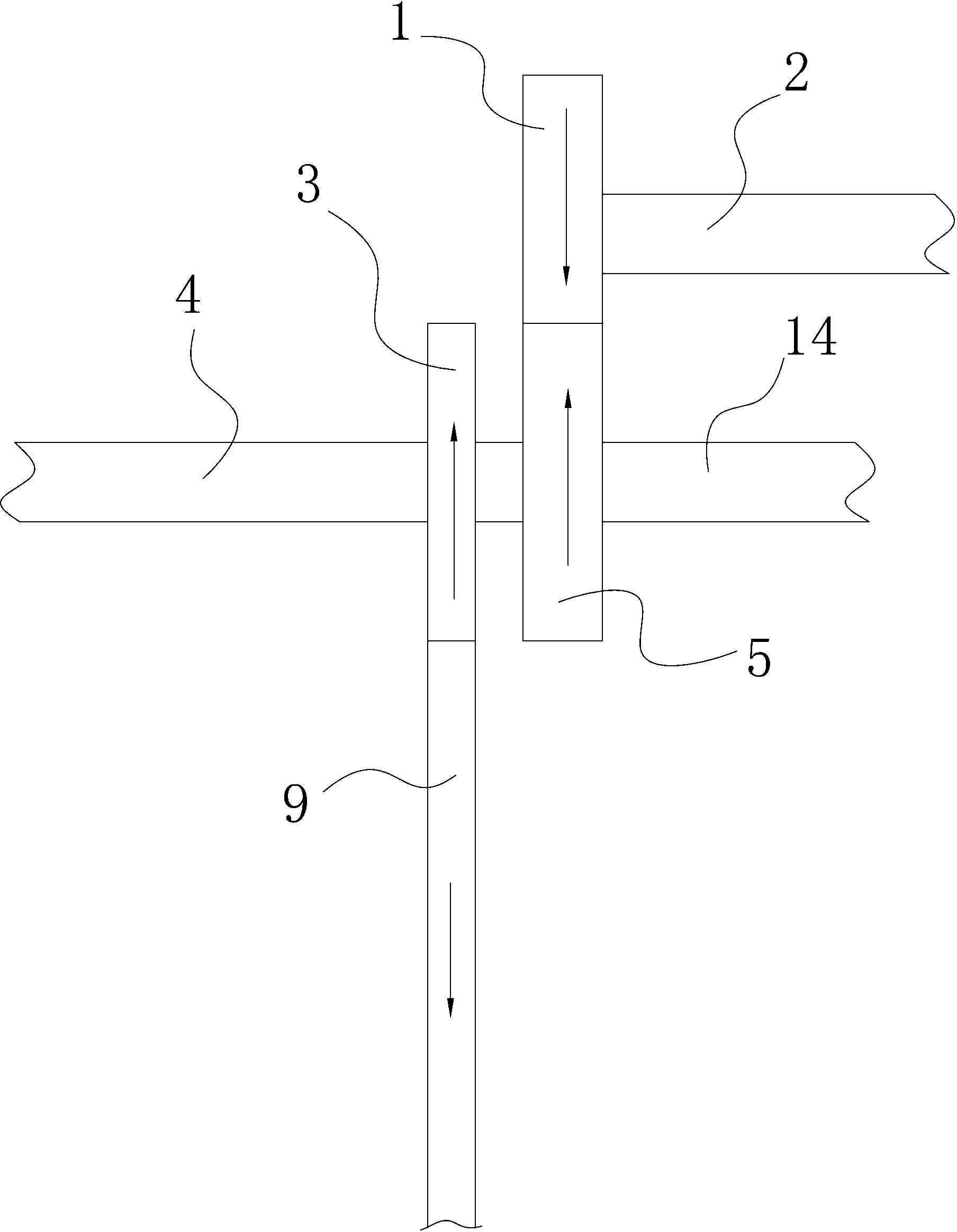

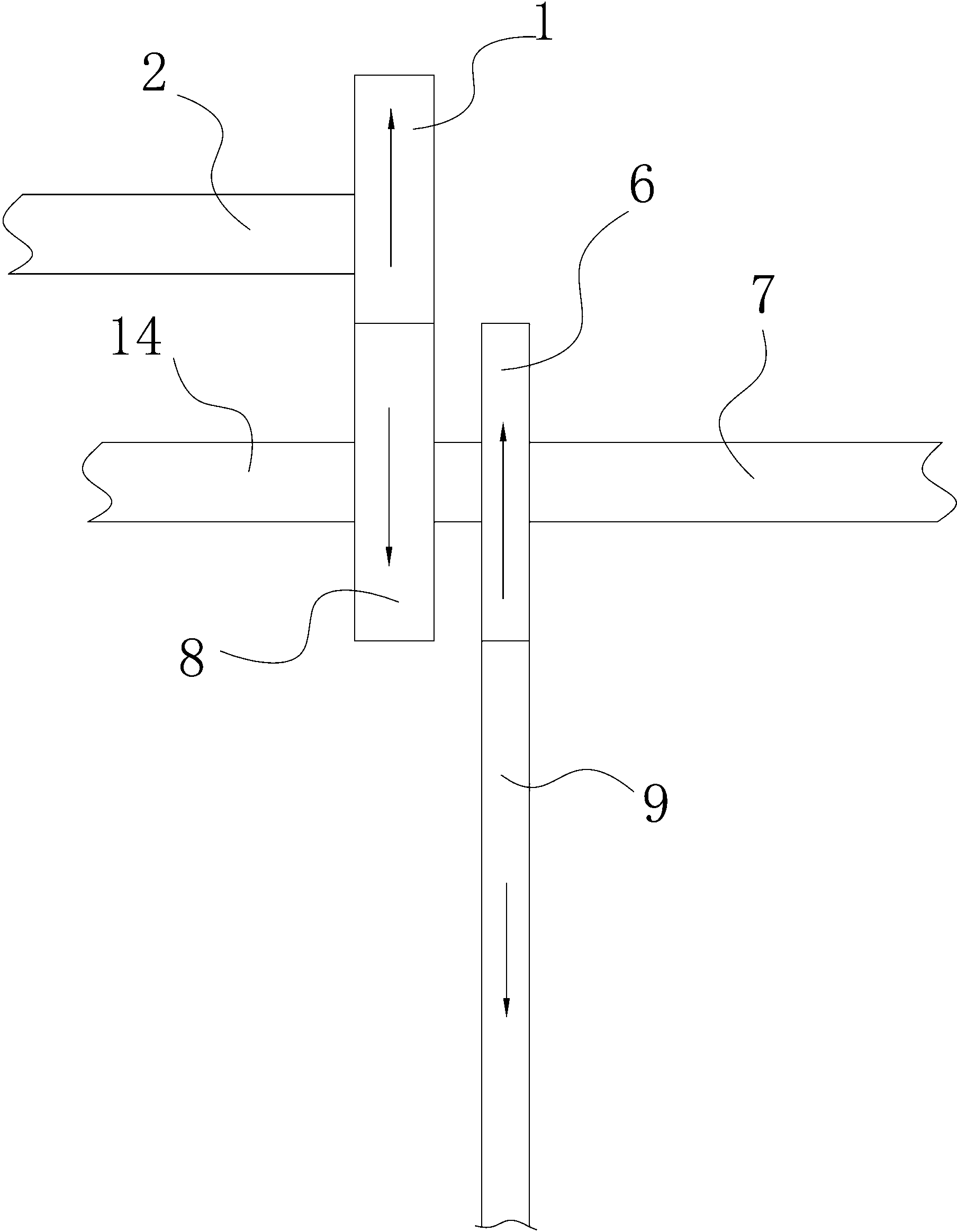

[0024] refer to figure 1 , figure 2 and image 3 , both sides of a reciprocating double-sided rack 9 of the present invention are respectively meshed with the first gear 3 and the second gear 6, the first gear 3 is fixedly connected with the first flywheel clutch 5 through the first transmission shaft 4, and the first gear 3 is fixedly connected with the first flywheel clutch 5. The outer peripheral gear of a flywheel clutch 5 meshes with the main shaft gear 1; the second gear 6 is fixedly connected with the second flywheel clutch 8 through the second transmission shaft 7 respectively, and the outer peripheral gear of the second flywheel clutch 8 also meshes with the main shaft gear 1 , Main shaft gear 1 is fixedly connected to main shaft 2.

[0025] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com