High-power LED (light-emitting diode) lamp module of chip-on-board

An LED lamp and high-power technology, which is applied in the parts of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of high heat generation, low light efficiency, light consumption, etc. Efficiency, improved lighting brightness, reduced usage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

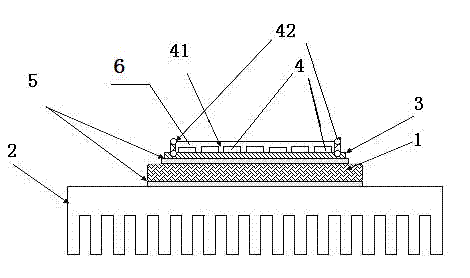

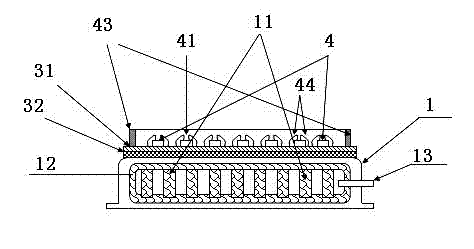

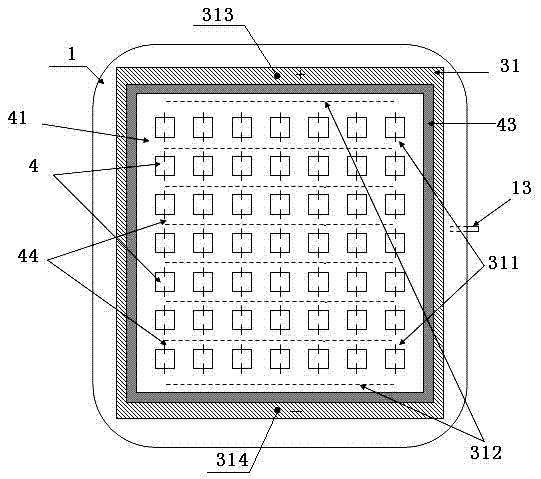

[0050] Combine below Figure 2 to Figure 9 , the present invention is further described:

[0051] Such as figure 2 As shown, the "chip on board" in the high-power LED lighting module of the chip on board refers to the chip directly packaged on the uniform temperature plate, and its specific structure is as follows:

[0052] Attach the capillary tissue 12 to the inner wall of the vapor chamber 1, seal the vapor chamber of the support, 11, and leave an injection port 13, and coat a layer of high thermal conductivity insulating medium on the upper surface of the vapor chamber 1 to form An insulating dielectric layer 32.

[0053] Then a circuit layer 31 is made on the insulating medium layer 32, and the first stage of the process is completed through the processes of die bonding, gold wire bonding, reflector support 43, and phosphor powder 41 (needed only for white light source).

[0054] To complete the structure of the above process, add working fluid to the injection port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com