Method for sealing organic light emitting diode by frit

A light-emitting diode and glass frit technology, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid-state devices, etc., can solve the problems of the influence of the bonding strength between the cover plate and the substrate, reducing the life of the light-emitting diode, and the large temperature gradient of the glass frit. , to achieve the effect of small implementation difficulty, improve yield and overall quality, and reduce thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

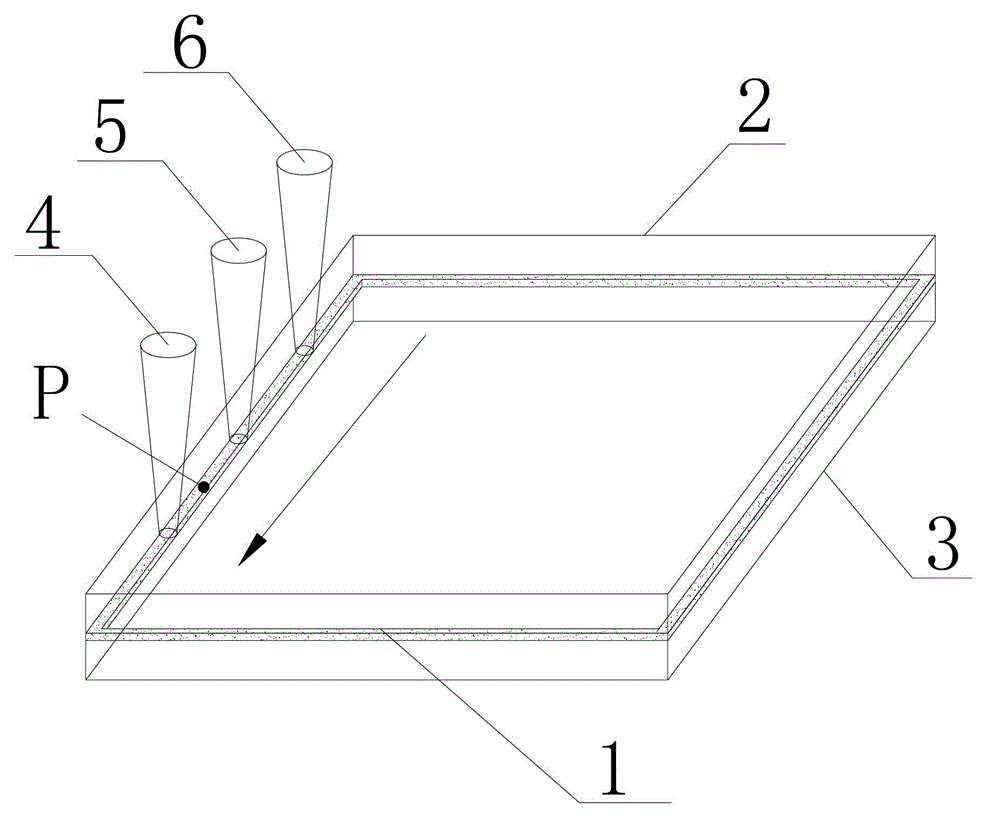

[0012] like figure 1 As shown, the glass frit 1 is arranged between the cover plate 2 and the substrate 3, the first laser beam 4 passes through the cover plate 2, focuses on the glass frit 1, heats the glass frit 1, and the temperature of the glass frit 1 rises instantaneously to reach At the melting point, the glass frit 1 melts to bond the cover plate 2 and the substrate 3 together. The glass frit 1 is cooled and solidified to form a glass wall and play a sealing role. The method for sealing the organic light-emitting diode with glass frit is to divide the heating of the glass frit 1 into three steps, that is, use the first laser beam 4 to preheat the glass frit 1, use the second laser beam 5 to melt the glass frit 1, and use the second laser beam 5 to melt the glass frit 1. The three laser beams 6 delay the cooling speed of the glass frit 1 . Taking point P in the figure as an example, the first laser beam 4 , the second laser beam 5 and the third laser beam 6 move in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com