Treatment agent for decomposition of chemical substance which comprises persulfuric acid salt and silver complex, and method for decomposition of chemical substance using same

A technology of chemical substances and persulfates, applied in organic chemistry, silver organic compounds, oxidized water/sewage treatment, etc., can solve problems such as difficult to degrade metal cyanide complexes, and achieve safe and effective degradation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075]Potassium hexacyanoferrite (special grade reagent manufactured by Kosou Chemical Co., Ltd.) was dissolved in pure water to prepare simulated polluted water with a concentration of 10 mgCN / L. 2,2'-bipyridine (a special grade reagent manufactured by Wako Pure Chemical Industries, Ltd.) as a complexing agent was dissolved in an aqueous sulfuric acid solution to prepare an acidic 2,2'-bipyridine aqueous solution of 0.16% by weight of sulfuric acid. Dissolve silver nitrate (special grade reagent manufactured by Kosou Chemical Co., Ltd.) as a silver compound in pure water to prepare a silver nitrate aqueous solution, and mix the above sulfuric acidic 2,2'-bipyridine aqueous solution to prepare silver as a silver complex. -2,2'-bipyridyl complex aqueous solution. 50.0 g of simulated polluted water was added to a glass sample tube, and 1.36 g of sodium acetate trihydrate (a special grade reagent manufactured by Koso Chemical Co., Ltd.) as a pH regulator and sodium persulfate (Ko...

Embodiment 2~4

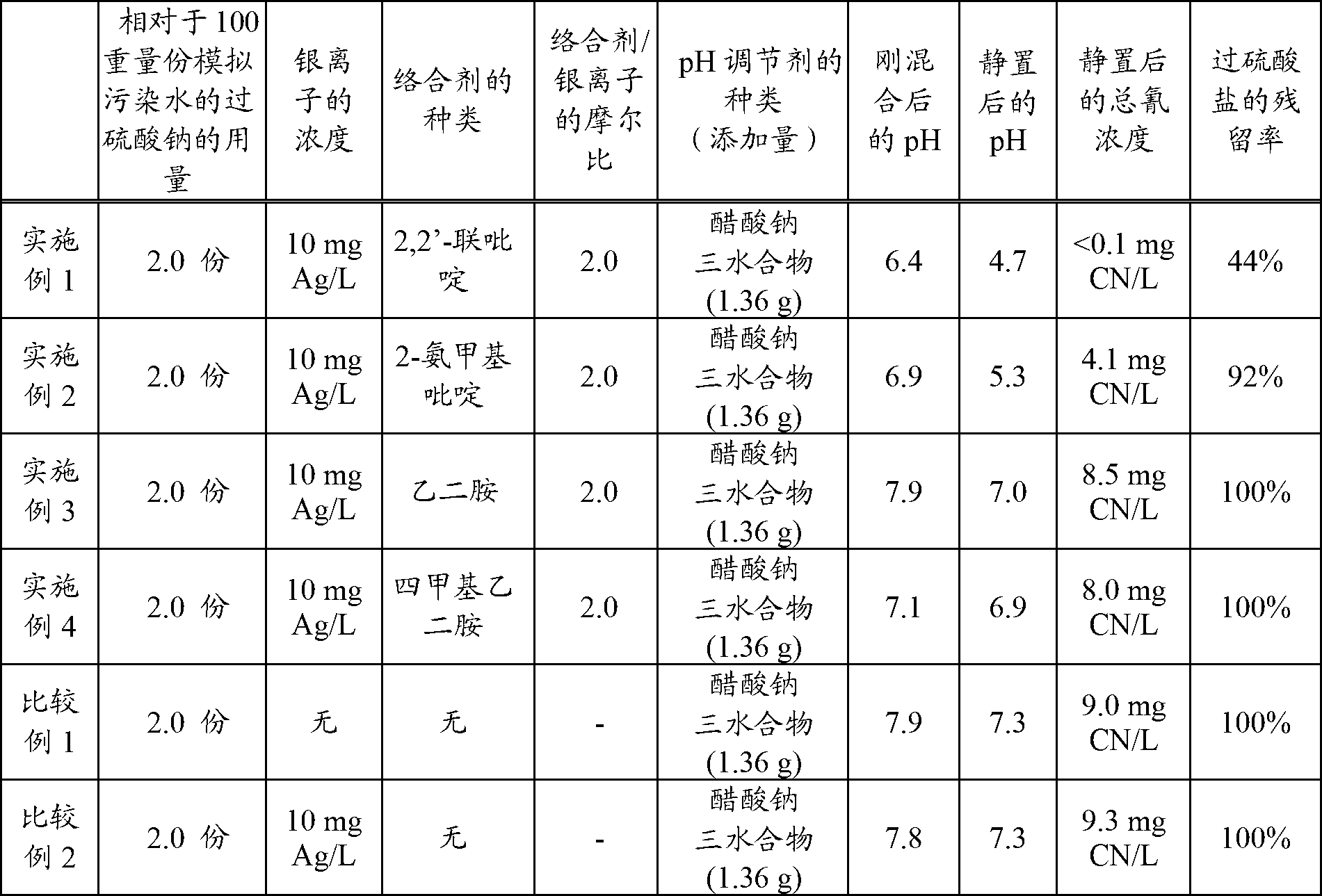

[0088] As a complexing agent, 2-aminomethylpyridine (a reagent manufactured by Tokyo Chemical Industry Co., Ltd.), ethylenediamine (a special grade reagent manufactured by Wako Pure Chemical Industries, Ltd.), or tetramethylethylenediamine (a reagent manufactured by Sigma-Aldrich Co., Ltd.) was used. .LLC. manufactured reagent) in place of 2,2'-bipyridine, the experiment was carried out in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 5~7

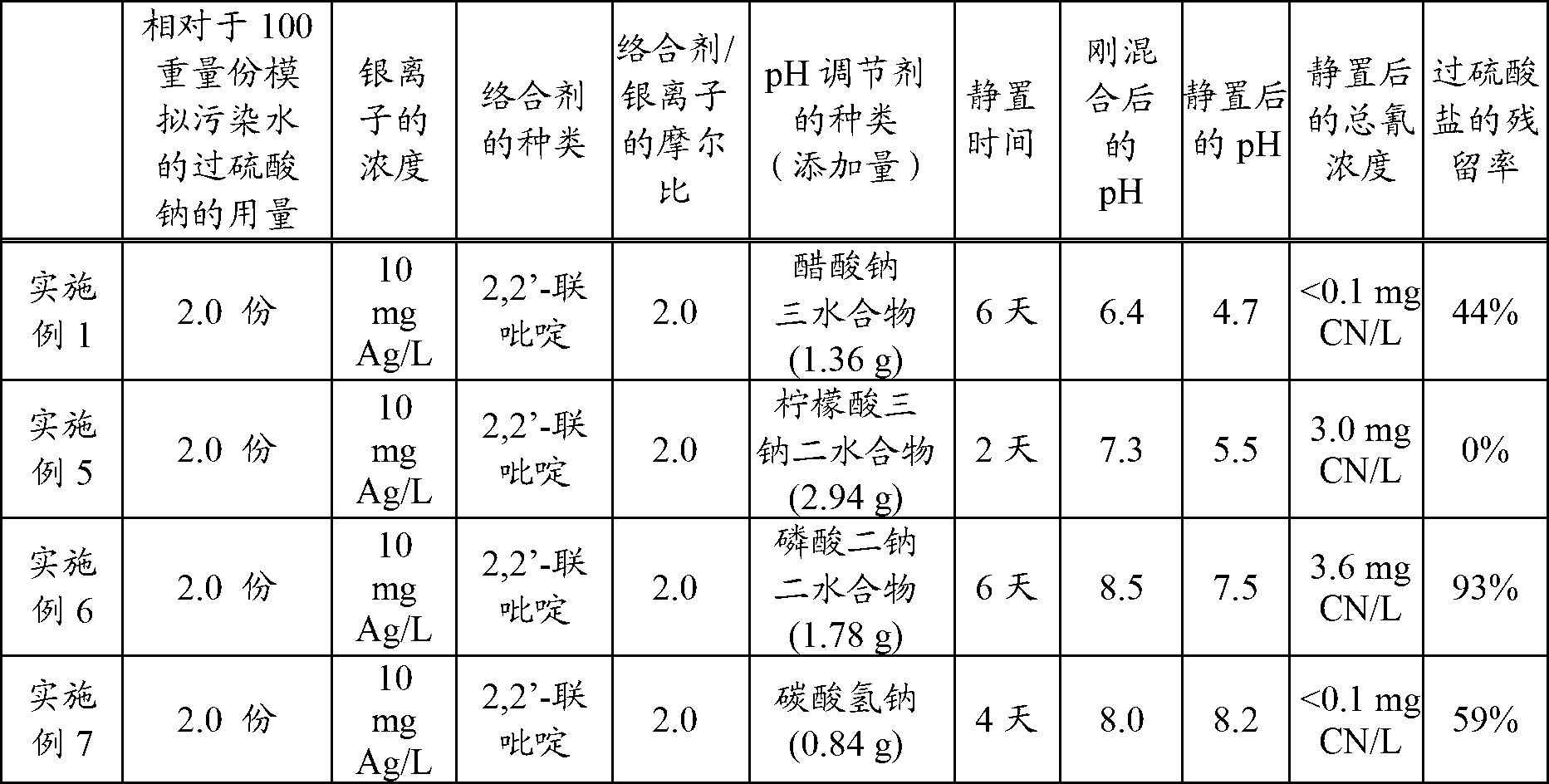

[0102] As a pH adjuster, use trisodium citrate dihydrate (special grade reagent manufactured by Komō Chemical Co., Ltd.), disodium phosphate dihydrate or sodium bicarbonate (special grade reagent manufactured by Komō Chemical Co., Ltd.) instead of acetic acid For sodium trihydrate, the experiment was carried out in the same manner as in Example 1 except that the standing time was 2 days, 6 days, or 4 days. The results are shown in Table 3.

[0103] [table 3]

[0104]

[0105] As shown in Table 3, acetic acid, citric acid, phosphoric acid and carbonic acid buffers can be used as pH regulators in the degradation method of the present invention. Especially, in the embodiment 1 that uses sodium acetate as pH regulator and the embodiment 7 that uses sodium bicarbonate as pH regulator, the degradation effect of cyanide is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com