Catalyst for selective hydrogenation of phenylacetylene in styrene

A technology of hydrogenation catalyst and phenylacetylene, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrocarbon, etc., and can solve the loss of styrene and the amount of styrene flow rubber High, incomplete hydrogenation of phenylacetylene, etc., to achieve the effect of prolonging service life, improving surface properties and acid properties, and avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Choose Al 2 o 3 -SiO 2 As carrier, according to the total mass of catalyst 100%, the mass content of Ni is 20%, the mass content of Zr is 2%, the mass content of W is 1.3%, and the mass content of Li is 6% of Ni. Among them, the BET specific surface area of the carrier is 140 m 2 / g, pore volume 0.5 ml / g, average pore diameter 10nm, bimodal pore structure.

[0023] The catalyst application effect:

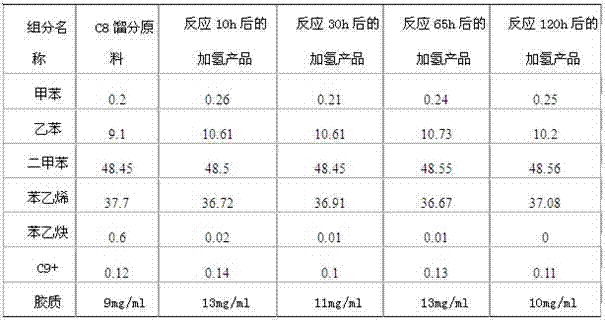

[0024] The ethylene cracking C8 fraction rich in xylene is used as the raw material, in which the concentration of styrene is 37.1%, and the concentration of phenylacetylene is 0.64%. A parallel-flow adiabatic bubbling fixed-bed reactor is adopted, the upper and lower beds are filled with catalyst, and the gas and liquid phase materials are fed at the bottom. The reaction conditions are feed temperature 20°C, reaction pressure 0.8Mpa, hydrogen-oil ratio 3, space velocity 5h -1 . The reaction results are shown in Table 1:

[0025] Table I

[0026]

Embodiment 2

[0028] Choose Al 2 o 3 -SiO 2 As a carrier, based on 100% of the total mass of the catalyst, the mass content of Ni is 13%, the mass content of Zr is 2.5%, the mass content of Cr is 1.1%, and the mass content of Li is 7% of Ni. Among them, the BET specific surface area of the carrier is 200 m 2 / g, pore volume 0.2 ml / g, average pore diameter 25nm, bimodal pore structure.

[0029] The catalyst application effect:

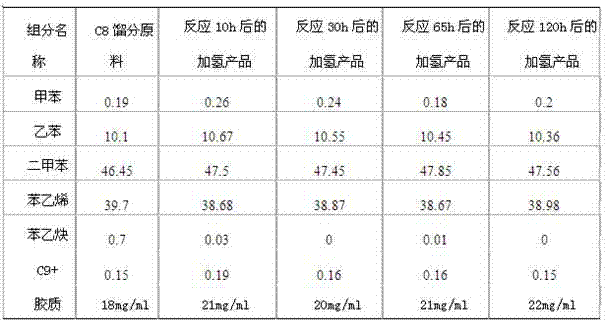

[0030] The ethylene cracking C8 fraction rich in xylene is used as the raw material, in which the concentration of styrene is 37.1%, and the concentration of phenylacetylene is 0.64%. A parallel-flow adiabatic bubbling fixed-bed reactor is adopted, the upper and lower beds are filled with catalyst, and the gas and liquid phase materials are fed at the bottom. The reaction conditions are feed temperature 30°C, reaction pressure 6Mpa, hydrogen-oil ratio 10, space velocity 20h -1 . The reaction results are shown in Table 2:

[0031] Table II

[0032]

Embodiment 3

[0034] Choose Al 2 o 3 -SiO 2 As carrier, according to the total mass of catalyst 100%, the mass content of Ni is 15%, the mass content of Zr is 2.5%, the mass content of Cr is 1.8%, and the mass content of Li is 8% of Ni. Among them, the BET specific surface area of the carrier is 160m 2 / g, pore volume 0.4ml / g, average pore diameter 16nm, bimodal pore structure.

[0035] The catalyst application effect:

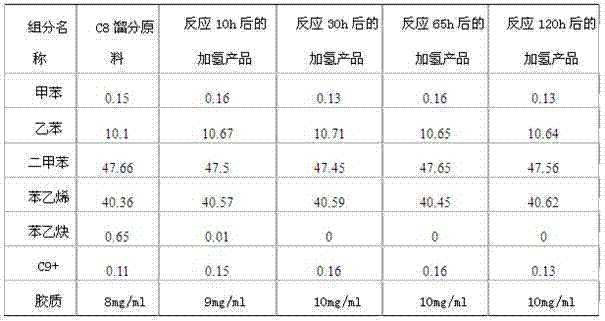

[0036] The ethylene cracking C8 fraction rich in xylene is used as the raw material, in which the concentration of styrene is 37.1%, and the concentration of phenylacetylene is 0.64%. A parallel-flow adiabatic bubbling fixed-bed reactor is adopted, the upper and lower beds are filled with catalyst, and the gas and liquid phase materials are fed at the bottom. The reaction conditions are feed temperature 25°C, reaction pressure 9Mpa, hydrogen oil ratio 20, space velocity 30h-1 . The reaction results are shown in Table 3:

[0037] Table three

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com