Rapidly-inflatable-deployment thin-film support tube for space craft

An inflatable deployment and support tube technology, which is used in aircrafts, aerospace vehicles, aerospace equipment, etc., can solve the problems of low deployment reliability, long deployment time, and length limitations of mechanical joints, and achieve stable and reliable deployment process. Short time, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

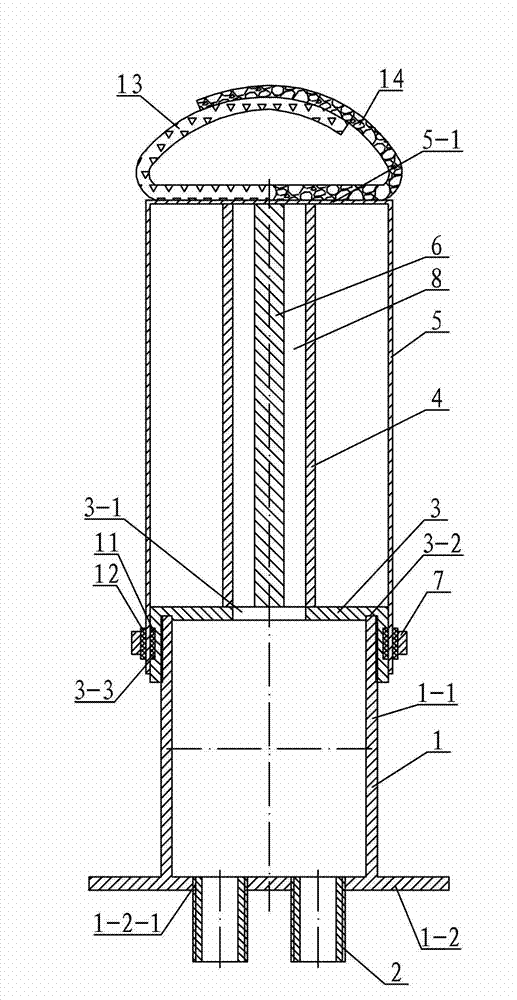

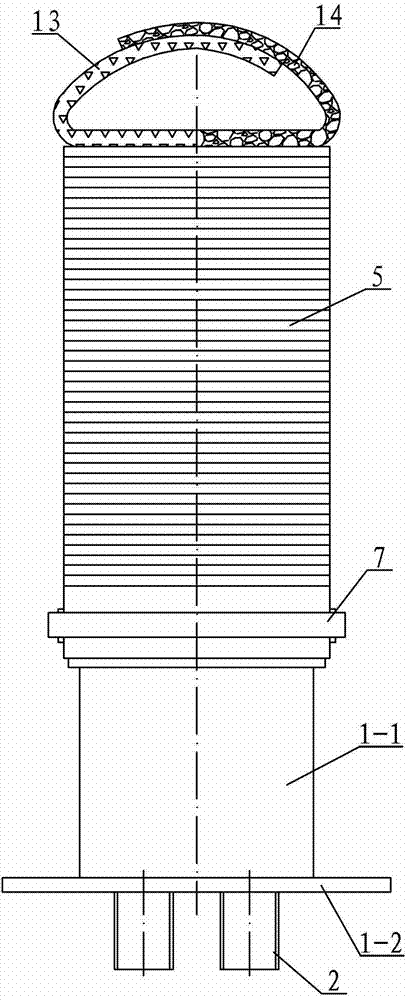

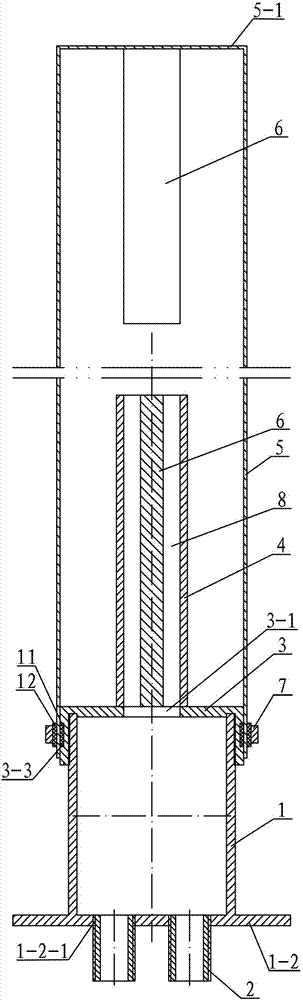

[0009] Specific implementation mode one: combine figure 1 , image 3 and Figure 6 Describe this embodiment, this embodiment includes air collector 1, upper end cover 3, airflow conduit 4, folded film tube 5, direction mark 6, clamp 7, direction mark conduit 8, inner rubber ring 11, outer rubber ring 12, adhesive Clasp 13, Velcro hair 14 and at least three connecting pipes 2, the air accumulator 1 includes a cylinder body 1-1 and a lower end cover 1-2, the lower end cover 1-2 is arranged at the lower end of the cylinder body 1-1, and the cylinder body 1 -1 is integrated with the lower end cover 1-2, the upper end cover 3 is arranged on the upper end of the cylinder 1-1, and the upper end cover 3 is threaded with the cylinder 1-1, and the upper end cover 3 is provided with the cylinder 1 The upper end cover vent hole 3-1 that the inner cavity of -1 communicates, the lower end cover 1-2 is evenly distributed along the same circumference with at least three lower end cover thre...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 5 To illustrate this embodiment, the cross-sectional shape of the direction mark 6 in this embodiment is in the shape of a "cross", and the cross-sectional shape of the lumen of the direction mark catheter 8 coincides with the "cross" shape of the direction mark 6. The "ten" shape enables the film support tube to run straight after inflated and expanded, and avoids twisting of the film support tube. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 6 To illustrate this embodiment, an annular groove 3-2 is provided at a position corresponding to the bottom end surface of the inner cavity of the upper end cover 3 of this embodiment and the upper end surface of the cylinder 1-1. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com