Method for producing sewage flocculating agent by utilizing dead catalyst

A waste catalyst and sewage production technology, applied in the direction of flocculation/sedimentation water/sewage treatment, aluminum chloride, aluminum halide, etc., can solve the problems of secondary pollution, high extraction cost, low heavy metal content, etc., and achieve the goal of saving treatment costs Effect

Inactive Publication Date: 2013-01-23

天津莱特化工有限公司

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Deep burial method: 100% treatment of spent catalysts, high one-time investment, and a qualified deep burial site is required, which will cause secondary pollution during road transportation

[0005] Extraction of heavy metals such as nickel: The heavy metal nickel in the spent catalyst is extracted by contacting Henan, Shandong and other units, but due to the low content of heavy metals, the extraction cost is high, and at the same time, the reduction and harmless treatment cannot be achieved

[0006] Storage method: Since the spent catalyst is a small particle with a very low particle size, it is difficult to store. At the same time, in the northern coastal area, it is dry and windy all year round. secondary pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

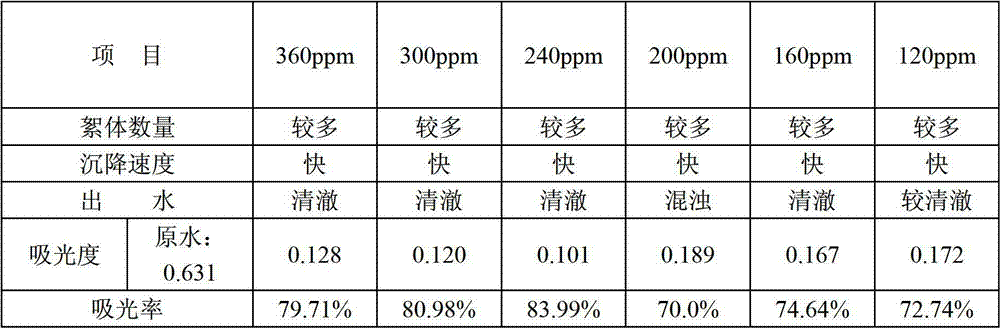

[0029] The following table 1 is the respective addition and reaction condition control of three embodiments:

[0030] Table 1

[0031] Example

[0032] Polymerization temperature

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for producing a sewage flocculating agent by utilizing a dead catalyst. The method comprises the following steps of: 1) pre-treatment: crushing the dead catalyst into particles of 40 -60 meshes, roasting and activating the particles for 6 -12 hours at a temperature of 600 -800 DEG C for later use; 2) polymerization reaction: adding strong acid and water into a reaction kettle, starting stirring and heating up, when the temperature reaches a predetermined value, feeding the dead catalyst and bauxite according to a certain proportion into the reaction kettle to react for 3 hours; 3) adjustment reaction: unloading reactants in the reaction kettle into an adjusting reaction tank from an unloading opening, adding a calcium aluminate powder and water according to a certain proportion to continue the reaction for 2 -2.5 hours; and 4) post-treatment: cooling the solution subjected to the adjustment reaction to the temperature of 40 DEG C, and filter-pressing the solution to obtain a liquid product. The method provided by the invention produces the sewage flocculating agent by utilizing the dead catalyst and completely solves the treatment difficulty of solid wastes in petrochemical corporations; the method provided by the invention creates a new growth point of profit as well as saves the treatment cost of solid wastes; and meanwhile, the method provided by the invention completely solves a pollution problem of the solid wastes to the environment.

Description

technical field [0001] The invention relates to the field of environmental protection, in particular to a production method of a sewage flocculant. Background technique [0002] The catalytic cracking unit of oil refinery produces a certain amount of waste catalyst every year. As waste residue, its environmental protection treatment has always been a difficult problem for oil refiners. After the catalyst is separated by the catalyst magnetic separation device, the remaining high magnetic catalyst is nearly 500 tons per year, which mainly contains Al 2 o 3 About 30%, the rest contains heavy metals Fe, Ni, Gu, etc. The catalyst is spherical solid powder, stable in state, insoluble in water, and can be melted when the temperature is as high as 1000 ° C. The heavy metals in the spent catalyst can be extracted, but due to low content, large investment and high operating costs, it is difficult to achieve. [0003] At present, there is no better treatment method for waste cataly...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/52C01F7/56

Inventor 齐勇郝日诗姚桂莹陈爱春袁波梁远凯苏超王军

Owner 天津莱特化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com