USR (Upflow Solids Reactor) fermentation technology method

A fermentation process, anaerobic fermentation technology, applied in the field of USR fermentation process, can solve problems such as restricting the development of breeding enterprises, polluting the living and ecological environment, and weak related technologies, so as to enhance and expand the radiation function, improve life and ecology Environment, effect of increasing circular factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

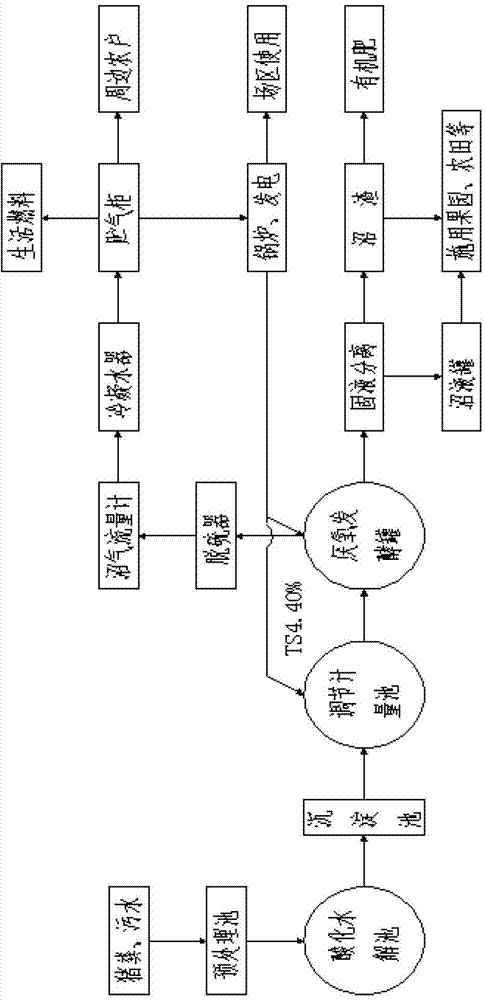

[0021] Such as figure 1 The USR fermentation process shown is to pretreat pig manure and sewage in the treatment tank. After the preliminary treatment, it is acidified and hydrolyzed in the acidified hydrolysis tank, then precipitated in the sedimentation tank, adjusted and measured, and fermented in the anaerobic fermentation tank. Fermentation is carried out at a fermentation temperature of 35°C for 15 days, and the virus killing rate is over 96%. The biogas, biogas residue and biogas slurry produced after fermentation are separated, and the biogas residue is used to produce organic fertilizer for use in farmland and orchards, etc., and the biogas slurry is stored in In the biogas slurry tank, the biogas enters the condenser through the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com