High-efficient clean utilization system of coal based on activated coke dry method flue gas purification technology

A flue gas purification and active coke technology, applied in the chemical industry, achieves significant economic and social benefits, good economic benefits, and resolves the contradiction between energy and the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

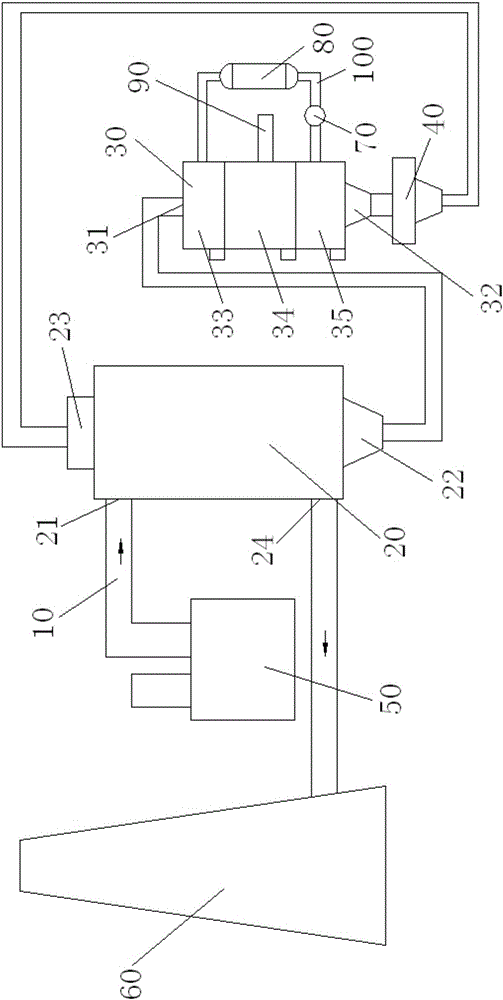

[0019] see figure 1 , figure 1 It is a structural schematic diagram of the high-efficiency and clean coal utilization system based on the active coke dry method flue gas purification technology of the present invention. An efficient and clean coal utilization system based on activated coke dry flue gas purification technology of the present invention includes a flue gas pipeline 10 , an adsorption desulfurization tower 20 and a desorption regenerator 30 .

[0020] Specifically, the adsorption desulfurization tower 20 is provided with a flue gas inlet 21, a flue gas outlet 22, an active coke inlet 23 and an active coke outlet 24, and the flue gas inlet 21 of the adsorption desulfurization tower 20 communicates with the flue gas pipeline 10, so The above-mentioned adsorption desulfurization tower 20 is used for adsorption and removal of sulfide in the flue gas.

[0021] The desorption regenerator 30 is provided with a regenerated active coke inlet 31 and a regenerated active c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com