Conjugated separate liquid crystal compound, and preparation method and application thereof

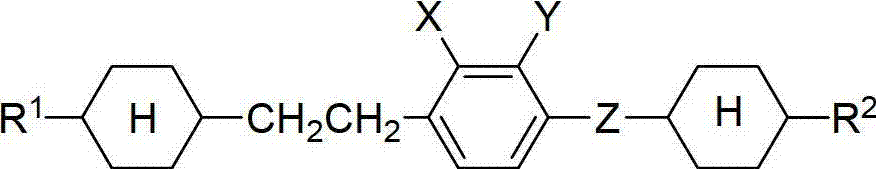

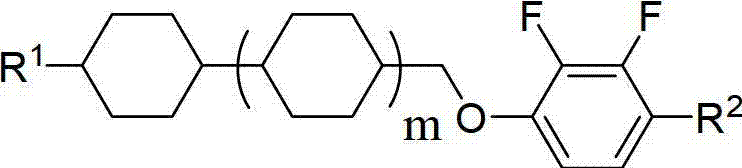

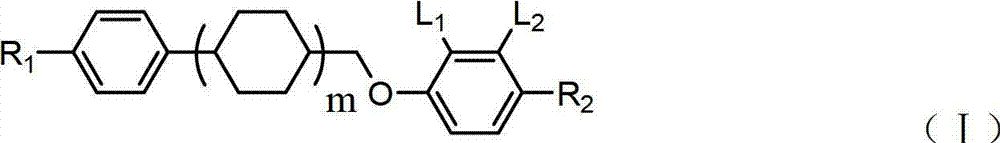

A compound and reaction technology, applied in the field of conjugated separation liquid crystal compound and its preparation, can solve the problems of low viscosity, isotropic state transition point (clearing point is not high enough, can not meet the needs of liquid crystal materials, etc., to achieve the raw material Easy to obtain, simple synthetic route, large optical anisotropy and clearing point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Compound I-1-2-1 (R 1 =C 3 H7,R 2 =C 2 h 5 ) preparation

[0049]

[0050] step 1:

[0051] Add 27.2g (4-(4-propylphenyl)cyclohexyl)methanol, 23.7g triethylamine and 400ml dichloromethane into a 1000ml three-necked flask. After cooling down to 0°C, a solution of 26.7g p-toluenesulfonyl chloride in 150ml dichloromethane was added, followed by reaction at room temperature for 3h. The reaction solution was poured into water, extracted with dichloromethane, and the organic layer was washed with water to neutrality, dried with anhydrous sodium sulfate, and then the solvent was removed by rotary evaporation, and recrystallized with ethanol to obtain 29g (4-(4-propyl Phenyl)cyclohexyl)methyl 4-methylbenzenesulfonate.

[0052] Step 2:

[0053] Add 8.4g of 4-ethoxy-2,3-difluorophenol and 60ml of N,N-dimethylformamide into a 500ml three-necked flask, cool down to 0°C, add 1.4g of sodium hydroxide in batches, and raise to 60°C , add dropwise a solution of 15....

Embodiment 2

[0055] Example 2 Compound I-5-2-1 (R 1 =C 3 h 7 , R 2 =C 2 h 5 ) preparation

[0056]

[0057] step 1:

[0058] Add 8g (4'-(4-propylphenyl)-[1,1'-dicyclohexane]-4-yl)methanol, 7.1g triethylamine and 200ml dichloromethane into a 1000ml three-necked flask. After cooling down to 0° C., a solution of 5.7 g of p-toluenesulfonyl chloride in 50 ml of dichloromethane was added, followed by reaction at room temperature for 3 h. The reaction solution was poured into water, extracted with ethyl acetate, and then the organic layer was washed with water to neutrality, dried with anhydrous sodium sulfate, and the solvent was removed by rotary evaporation, and recrystallized with ethanol to obtain 10 g (4'-(4-propane phenyl)-[1,1'-dicyclohexane]-4-yl)methyl 4-methylbenzenesulfonate.

[0059] Step 2:

[0060] Add 4.5g of 4-ethoxy-2,3-difluorophenol and 60ml of N,N-dimethylformamide into a 500ml three-necked flask, cool down to 0°C, add 1.4g of sodium hydroxide in batches, and rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com