Transformation method for waste dump micro-landform of large opencast coal mine in loess area

A technology for open-pit coal mines and dumps, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as difficulty in surface runoff drainage, hidden dangers of dump stability, and blockage of drainage ditches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

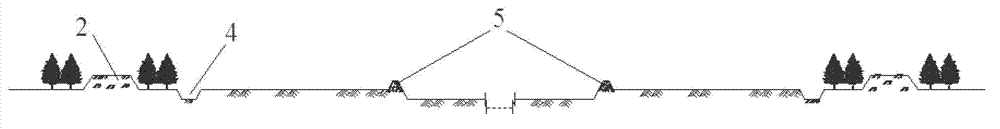

[0043] Such as Figure 5 Design drawing of typical field plots for micro-topographic reconstruction of Antaibao internal dump;

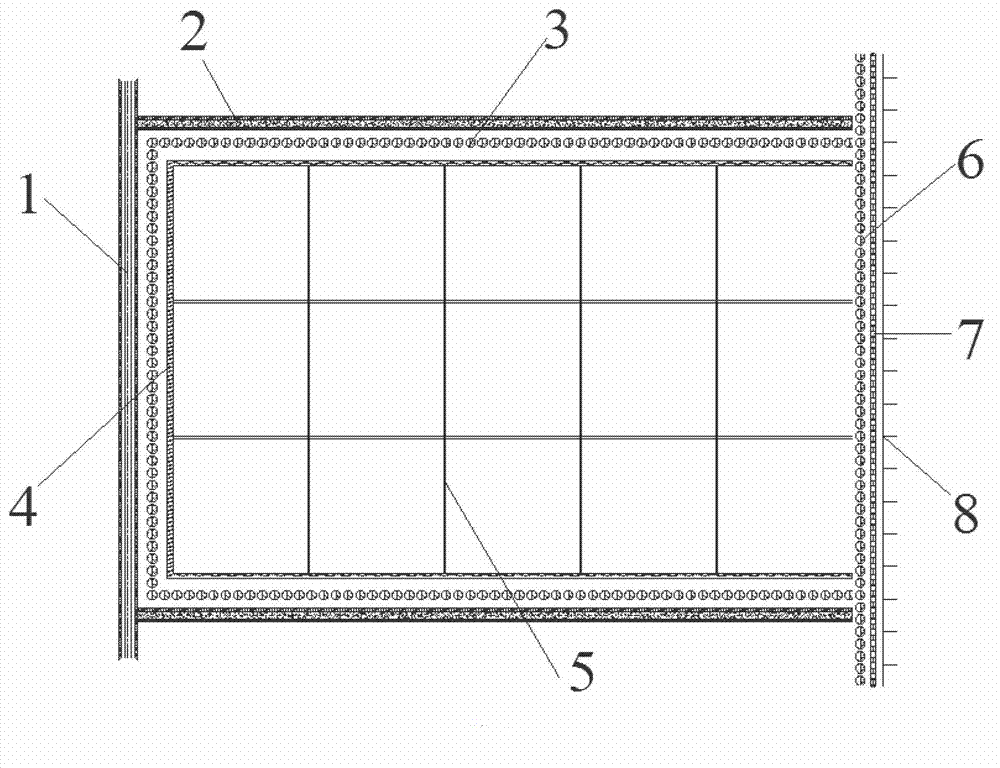

[0044] In 2011, the reclamation area of Antaibao internal dump was 63.40hm 2 , which is the top platform of the dump, the platform elevation is about 1480m, and the side slope is 30m high. The entire reclamation area is divided into 16 water storage units through field road 1 and production road 2 to carry out micro-terrain reconstruction, and a water retaining wall 7 is built on the side of the slope shoulder length direction of the top platform, and the water retaining wall 7 is built in the field Road storage ditches 4 are arranged on both sides of the road 1 and the production road 2, and field ridges are arranged in the water storage units.

[0045] Take a field 8 on the top platform of the dump in Antaibao as an example. The field is 250m long, 150m wide, and has a total area of 37,500m 2 The length of the field road is 150m, and the len...

Embodiment 2

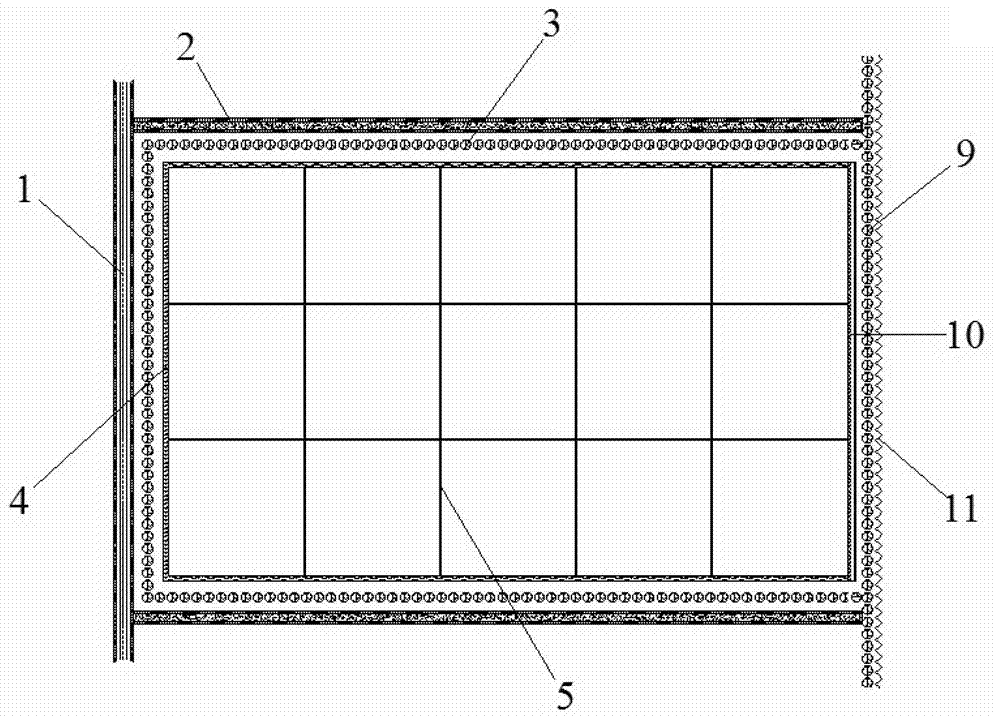

[0049] Such as Figure 6 Design drawing of typical field plots for micro-topographic reconstruction of dump site in Anjialing;

[0050] In 2011, the reclamation area of Anjialing internal dump was 171.51hm 2 , divided into three steps, the highest platform elevation is about 1420m, and the lowest platform elevation is about 1340m. Through field road 1 and production road 2, the entire reclamation area is divided into 26 water storage units for micro-terrain reconstruction, four projects of water retaining wall 7, road water storage ditch 4 and field ridge 5.

[0051] Taking a field on the top platform of the dump in Anjialing as an example, the field is 250m long, 150m wide, and has a total area of 37,500m 2 The total length of the field road is 400m, and the length of the production road is 250m. The slope protection forest 9 and the slope storage ditch 10 are arranged on both sides of the field road 1 and the production road 2; And slope storage ditch 10.

[0052] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com