Stander of high-speed data transmission system between rotary body and fixed body

A high-speed data transmission, fixed body technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problem of not meeting the requirements of the data transmission system, and achieve the effect of simple structure, high efficiency, and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the specific drawings and embodiments.

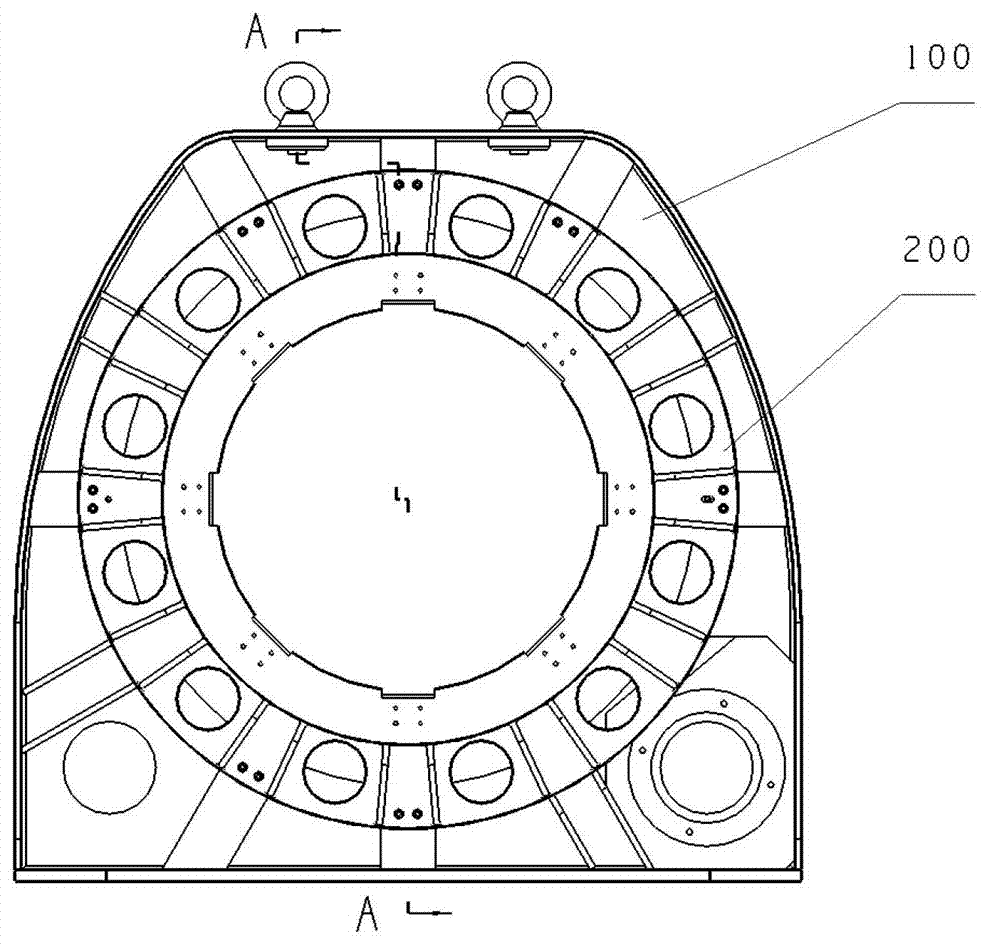

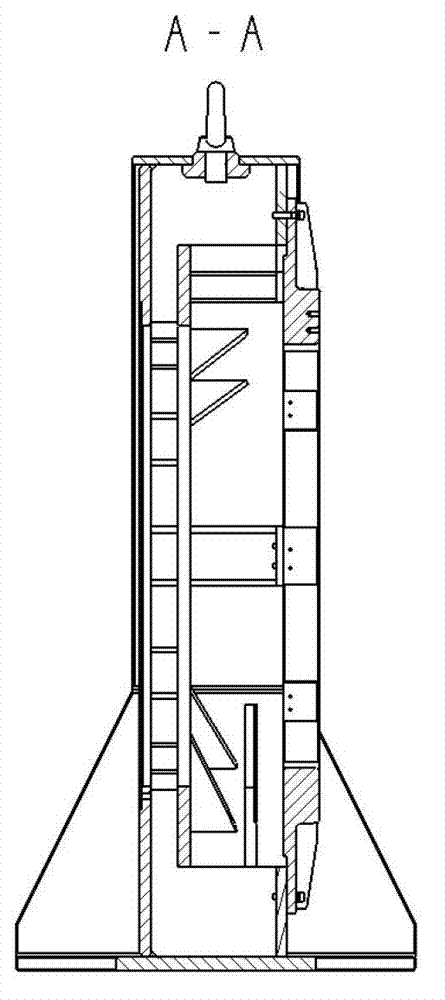

[0017] like figure 1 , 2 As shown, the rack in this embodiment is mainly composed of rack assembly 100 and receiving device mounting part 200 .

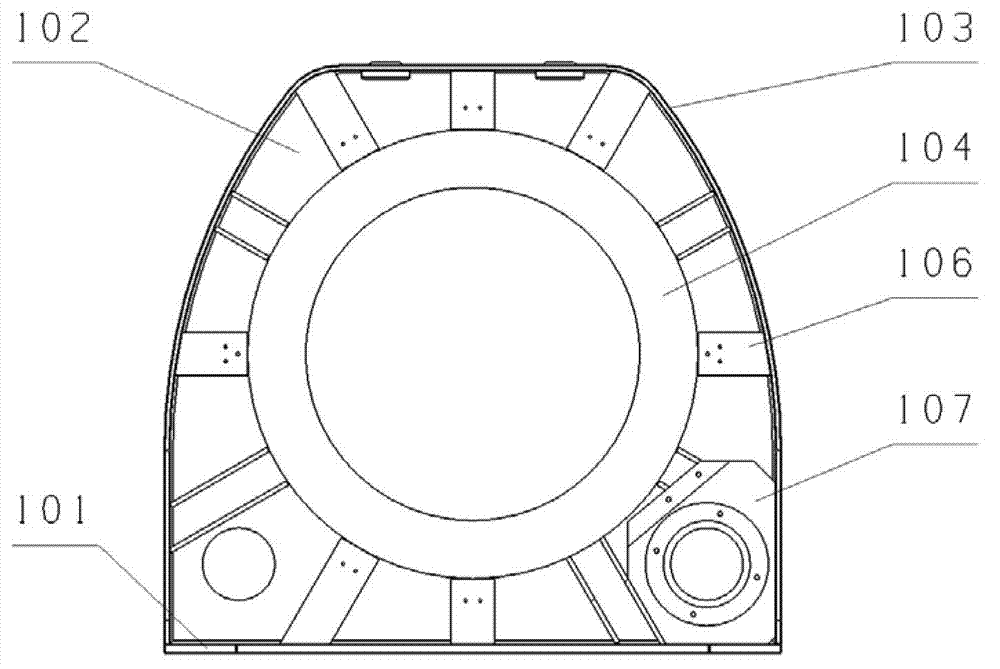

[0018] like Figures 3 to 6 As shown, the rack assembly 100 in this embodiment includes: a bottom plate 101, a vertical plate 102, an inverted U-shaped frame 103, a circular ring plate 104, a trapezoidal plate 105, a plurality of receiving device mounting plates 106, a motor mounting plate 107, a plurality of Each rib 108, etc., are fixedly connected between them. The bottom plate 101 is in the shape of an I-shape, and is laid flat on the bottom of the whole rack welding assembly 100; there is a through hole in the center of the vertical plate 102, the bottom of the vertical plate 102 is vertically fixed on the bottom plate 101, and the upper part of the vertical plate 102 has the same shape as the inverted U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com