Heat pipe heat extraction system in high-radiating density machine room

A technology of heat removal system and high heat dissipation, which is applied in the direction of air conditioning system, heating and ventilation control system, heating and ventilation safety system, etc. Large-scale adoption and other issues, to achieve the effect of increasing the number of cabinet servers, reducing the floor space of the computer room, and efficient heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

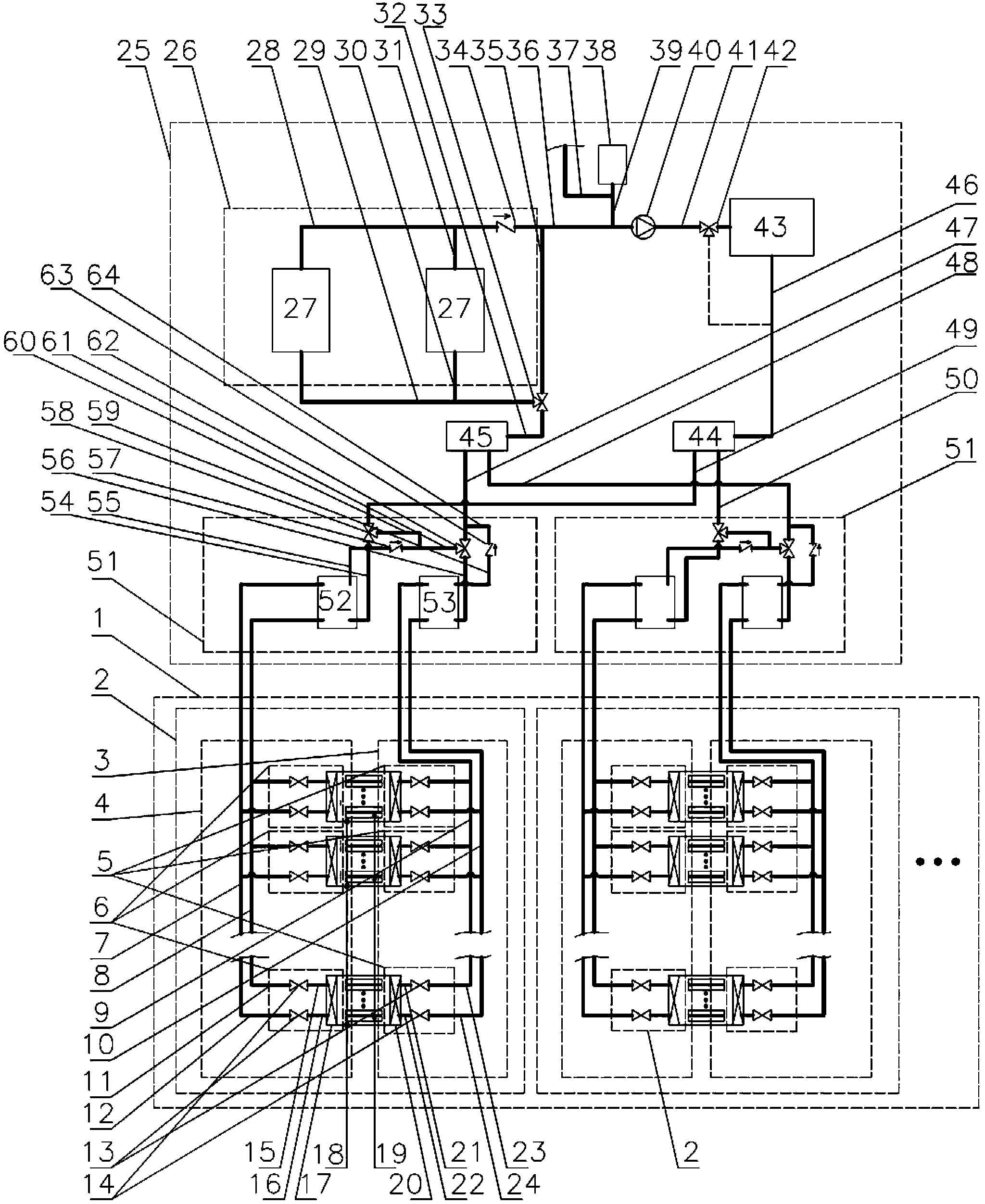

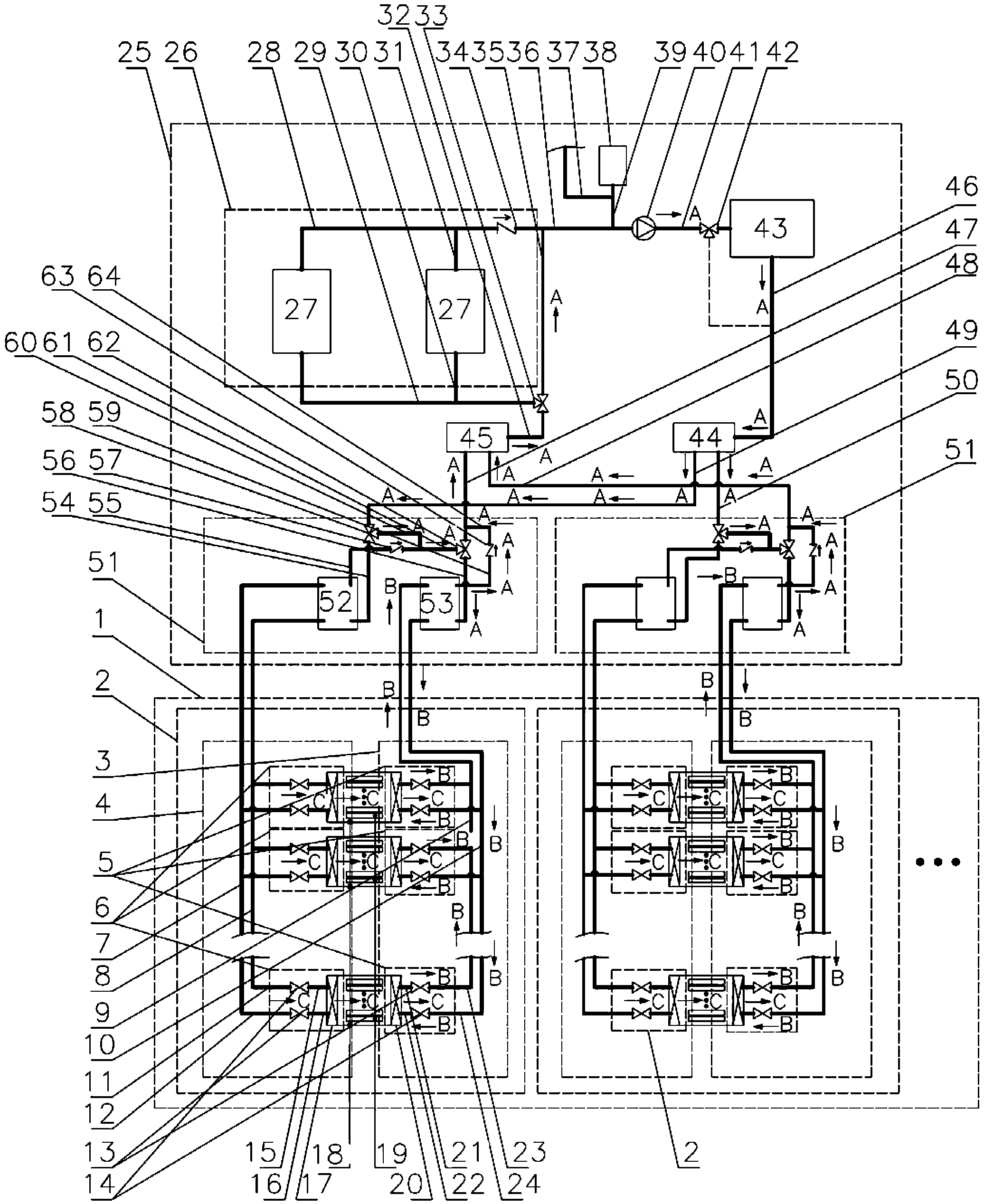

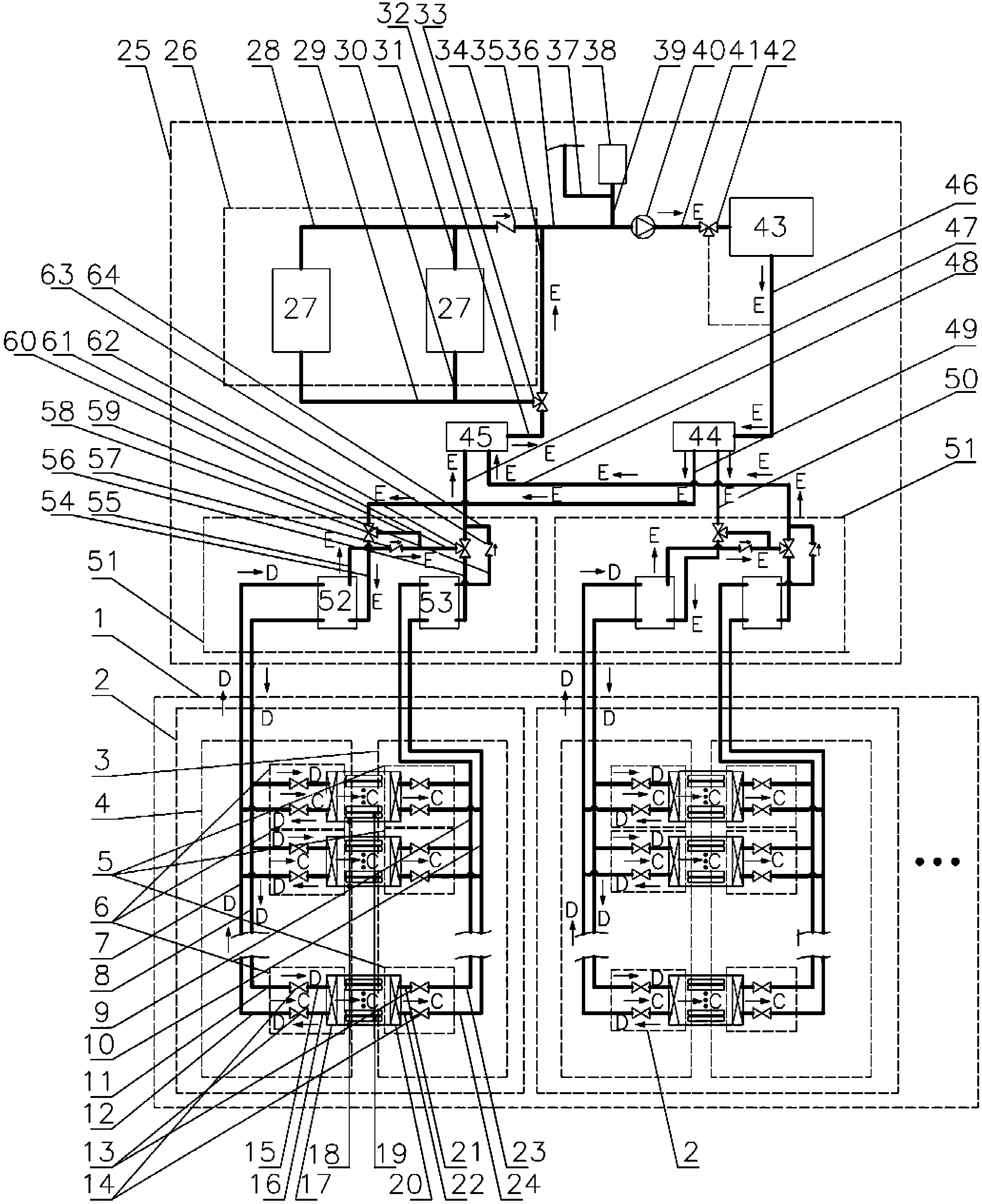

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0043] figure 1 It is a structural schematic diagram of the heat pipe heat removal system of the high heat dissipation density computer room of the present invention. The high heat dissipation density heat pipe heat removal system of the computer room of the present invention includes the indoor unit 1 of the computer room and the outdoor unit 25 of the computer room. Among them, the indoor unit 1 of the computer room is composed of several independent integrated cabinet heat pipe heat removal first-level subsystems 2; 18. Servers in a high heat dissipation density computer room 19, composed of the secondary heat dissipation subsystem 4 of the heat pipe on the front backplane; the secondary heat dissipation subsystem 3 of the heat pipe on the rear back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com