Lithium ion battery and preparation method thereof

A lithium-ion battery and cell technology, which is used in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of easy leakage of liquid lithium-ion batteries and poor battery safety performance, and avoid external mechanical damage. , The effect of preventing battery leakage and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

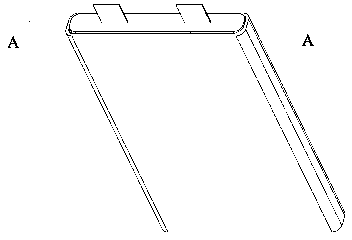

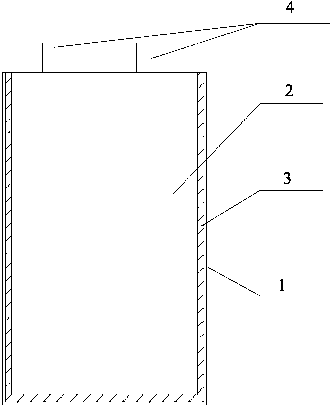

[0021] As common knowledge of those skilled in the art, positive and negative tabs are drawn out from the battery cell for drawing out the internal current of the battery. The tabs can all be drawn out from one end face of the battery core, or can be drawn out from two end faces of the battery core respectively, which is not specifically limited in the present invention. As a preferred embodiment of the present invention, the tabs 4 are all drawn out from one end face of the cell; then the gel porous protective film 3 is wrapped around the cell 2 and the other end face where the tabs are not drawn out, such as figure 2 shown.

[0022] The present invention also provides the preparation method of described lithium ion battery, comprises the following steps:

[0023] A. Dissolving a polymer that can be swollen by an electrolyte in a solvent system to form a polymer solution, then coating the polymer solution on a porous substrate, and obtaining a polymer porous membrane after ...

Embodiment 1

[0034] (1) Preparation of polymer porous membrane: Dissolve 6 parts by weight of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) in 94 parts by weight of acetone and stir evenly to obtain a polymer solution; the polyethylene porous substrate The polymer porous membrane A1 was obtained after being immersed in a polymer solution, taken out and dried.

[0035] (2) Preparation of battery cell: the positive electrode sheet containing lithium cobaltate and the negative electrode sheet containing artificial graphite are wound together with a polyethylene microporous separator with a thickness of 16 μm inserted thereinto, and a battery cell with a winding structure is assembled. One end of the cell leads out to a tab.

[0036] (3) Preparation of lithium-ion battery: use the polymer porous membrane A1 of step (1) to wrap the four sides of the battery cell and a bottom surface where the tabs are not drawn out, and then insert it into the battery case as a whole, inject electrolyte,...

Embodiment 2

[0038] The lithium-ion battery S2 of this example was prepared in the same manner as in Example 1, the difference being that:

[0039] In step (1), 6 parts by weight of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) was dissolved in a solvent system containing 89 parts by weight of acetone and 5 parts by weight of water, and stirred evenly to obtain this example polymer solution; the polypropylene porous substrate is immersed in the polymer solution, taken out and dried to obtain the polymer porous membrane A2;

[0040] In step (2), the polyethylene microporous membrane with a thickness of 20 μm was used instead of the polyethylene microporous membrane with a thickness of 16 μm in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com