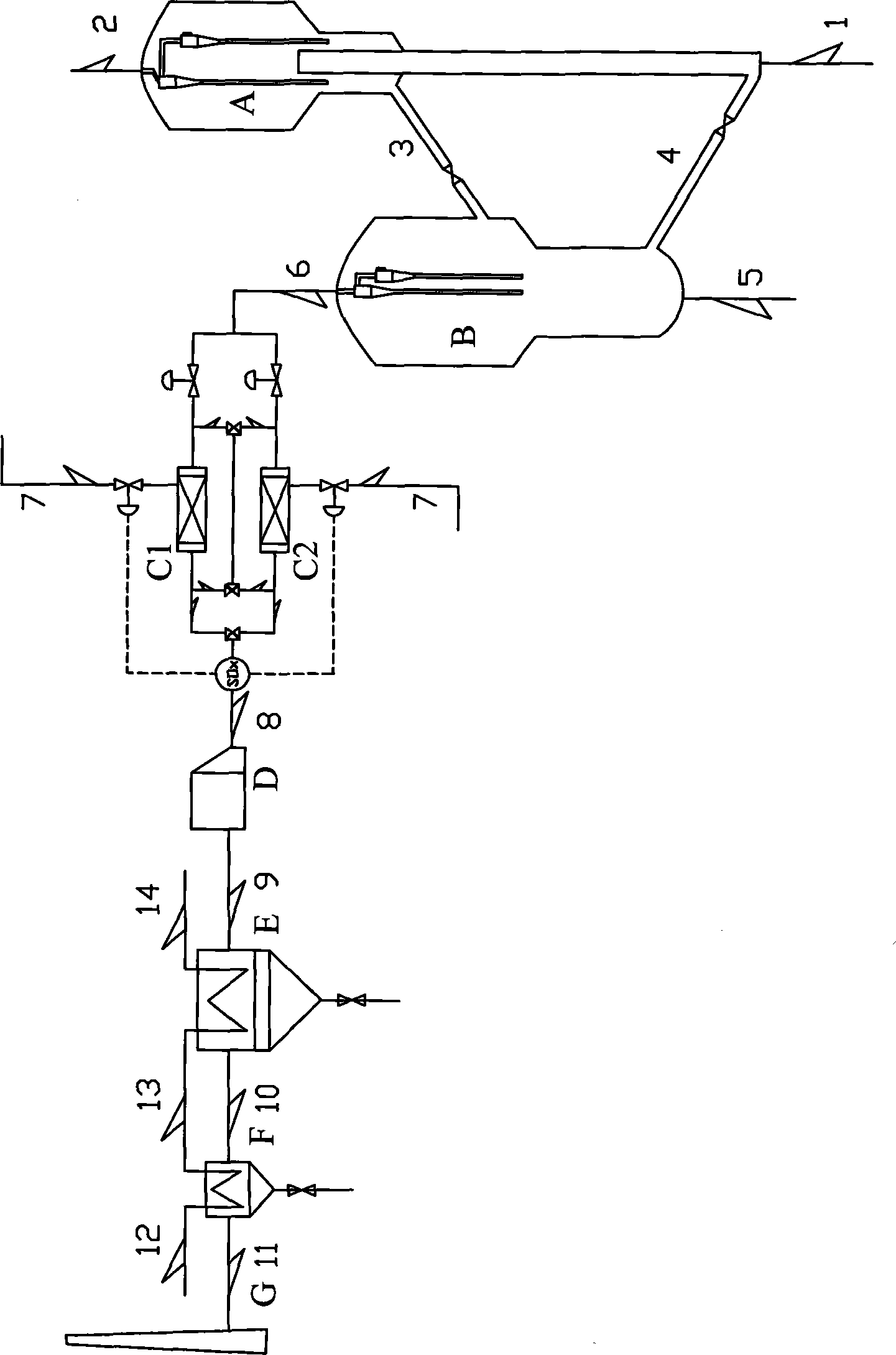

Method for simultaneously removing sulfur oxides, nitrogen oxides and carbon monoxide from flue gas

A technology of sulfur oxides and nitrogen oxides, applied in chemical instruments and methods, separation methods, preparation/purification of sulfur, etc., can solve the problems of treatment technology, flue gas and dry gas that have not yet been seen, and achieve simplification The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] A continuous flow fixed bed reactor (Φ20×600mm) made of quartz material is used. 5.0g of catalyst is filled in the reactor. The reactor is heated and controlled by a three-stage electric furnace. The flue gas contains eight components: O 2 , CO, CO 2 , SO 2 , NO, NO 2 、H 2 O, N 2 , the reducing gas contains four components: H 2 、CH 4 、H 2 S, N 2 . The composition of the mixed gas after the flue gas and reducing gas are mixed is shown in Table 1. The mixed gas is introduced into the reactor as raw material gas, and the gas flow rate is 3000ml / min. The content of each component in the mixed gas and reaction tail gas was determined by chromatography-mass chromatography.

[0046] See Table 2 for the tail gas composition at normal pressure, 650°C, and when the reaction reaches equilibrium. It can be seen from Table 2 that only 45ppm of SO is contained in the reaction tail gas 2 , far below the emission standard of 190ppm.

[0047] Table 1

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com