Ferro-chrome composite oxide and preparation method and application thereof

A composite oxide, iron-chromium technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of increasing the cost of sewage treatment, consumption of large sulfuric acid and sodium hydroxide, etc., to achieve high sewage treatment efficiency, simple operation, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

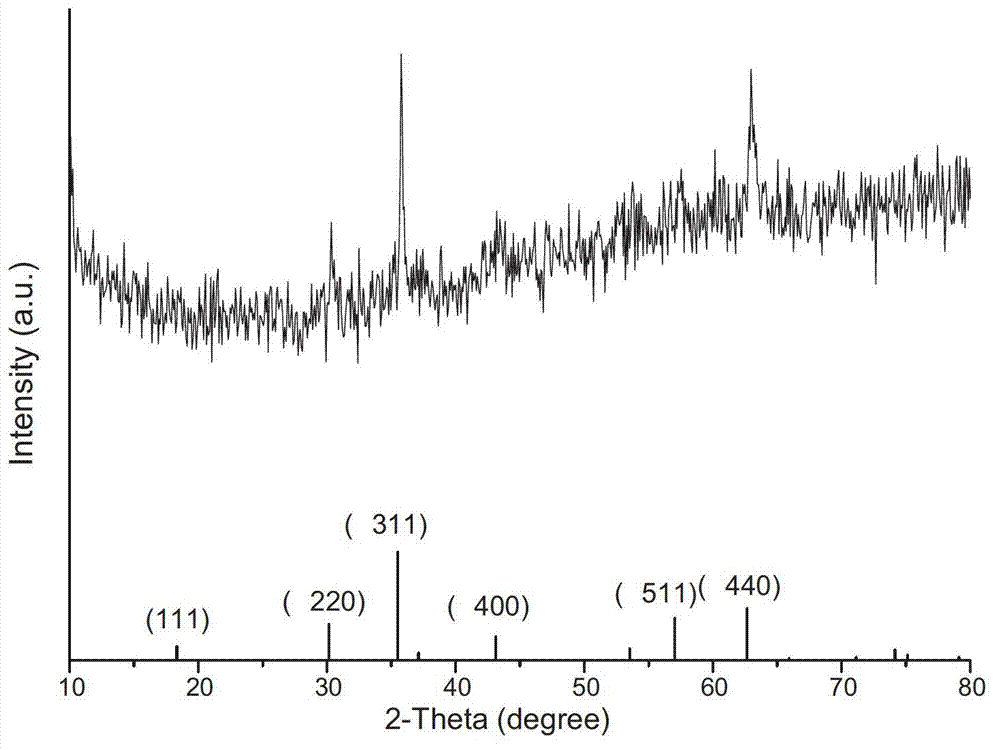

Image

Examples

preparation Embodiment 1

[0029] S1, add 26ml of water to the mixture of 16g sodium hydroxide and 7.65g sodium nitrate, stir until the solids are all dissolved to obtain the first mixed solution;

[0030] S2, under stirring, add dropwise hydrochloric acid with a concentration of 1.3 mol / L to a mixture of 5.35665 g of chromium trichloride hexahydrate and 50.2358 g of ferrous sulfate heptahydrate, and stir until all the solids are dissolved to obtain a second mixed solution;

[0031] S3, under an inert gas environment, after heating the second mixed solution to 96°C, add the first mixed solution prepared in S1 dropwise at a rate of 11ml / min until the addition is completed;

[0032] S4, keep the reaction solution obtained in S3 at 95°C for 2 hours, then cool to 25°C, centrifuge, separate the solid, then wash the solid with deionized water, dry the washed solid to obtain the iron-chromium composite oxide .

[0033] The particle size of the prepared iron-chromium composite oxide is 30nm.

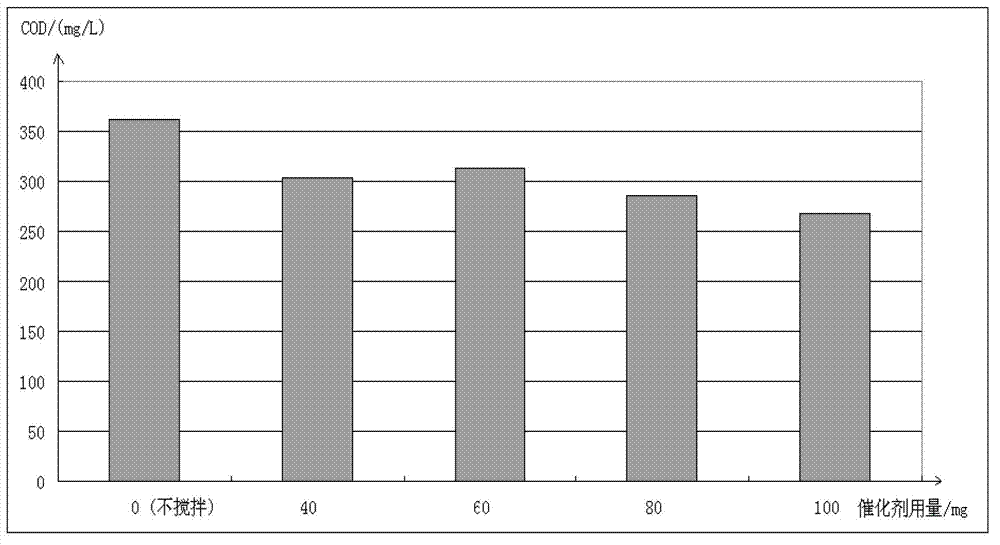

[0034] Use th...

preparation Embodiment 2

[0037] S1, add 10ml of water to the mixture of 16g sodium hydroxide and 7.65g sodium nitrate, stir until the solids are all dissolved, to obtain the first mixed solution;

[0038] S2, under stirring, add dropwise hydrochloric acid with a concentration of 1.2mol / L to a mixture of 5.35665g chromium trichloride hexahydrate and 87.5422g ferrous sulfate heptahydrate, and stir until all the solids are dissolved to obtain a second mixed solution;

[0039] S3, under an inert gas environment, after heating the second mixed solution to 90°C, add the first mixed solution prepared in S1 dropwise at a rate of 5ml / min until the addition is completed;

[0040] S4, keep the reaction solution obtained in S3 at 92°C for 2 hours, then cool to 23°C, centrifuge, separate the solid, then wash the solid with deionized water, dry the washed solid to obtain the iron-chromium composite oxide .

[0041] The particle size of the obtained iron-chromium composite oxide is 23nm, and the structural formul...

preparation Embodiment 3

[0044] S1, add 50ml water to the mixture of 16g sodium hydroxide and 7.65g sodium nitrate, stir until all solids are dissolved, obtain the first mixed solution;

[0045] S2, under stirring, add dropwise hydrochloric acid with a concentration of 1.1 mol / L to a mixture of 5.35665 g of chromium trichloride hexahydrate and 30.0790 g of ferrous sulfate heptahydrate, and stir until all the solids are dissolved to obtain a second mixed solution;

[0046] S3, under an inert gas environment, after heating the second mixed solution to 100°C, add the first mixed solution prepared in S1 dropwise at a rate of 15ml / min until the addition is completed;

[0047] S4, keep the reaction solution obtained in S3 at 96°C for 2 hours, then cool to 27°C, centrifuge, separate the solid, then wash the solid with deionized water, dry the washed solid to obtain the iron-chromium composite oxide .

[0048]The obtained iron-chromium composite oxide has a particle size of 25 μm and a structural formula o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com