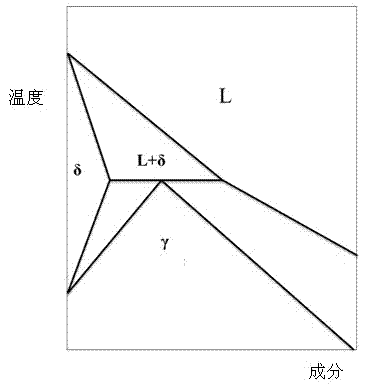

Method for improving isometric crystal rate of casting blanks through two-phase competition in peritectic alloy

An equiaxed crystal ratio and alloy technology, which is applied in the field of metal solidification structure growth process control, can solve the problems of not finding complete relevant literature, etc., to improve the solidification structure and internal quality, increase the equiaxed crystal ratio, and reduce the internal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, Fe-Ni, a typical peritectic alloy, is selected as the model alloy for research.

[0027] The concrete processing steps of the present embodiment are as follows:

[0028] 1) Vacuum arc melting alloy: melting Fe-Ni alloy. First use electric arc to melt the raw material into a liquid state, and then turn on magnetic stirring to make the alloy composition uniform while continuing to smelt, and the magnetic stirring current is about 0-8A. Melt and stir the alloy repeatedly for 3-5 times.

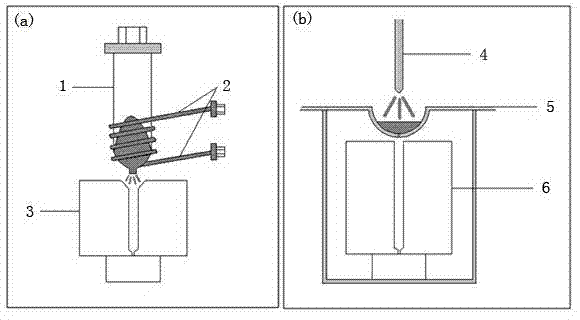

[0029] 2) Preparation of thin strips by vacuum spray casting: figure 2 (a) Schematic diagram of the experimental equipment for electromagnetic induction melting and spray casting. The main experimental process is to use vacuum electromagnetic induction to melt the master alloy in the glass tube. After the alloy is melted evenly, a certain air pressure is applied to the alloy melt. Alloy strip. Design of spray-casting copper mold: Make a 1.0mm cuboid cavity on the ...

Embodiment 2

[0034] In this embodiment, Fe-Mn peritectic alloy is selected for research.

[0035] The concrete processing steps of the present embodiment are as follows:

[0036] 1) Vacuum arc melting alloy: melting Fe-Mn alloy.

[0037] 2) Preparation of thin strips by vacuum suction casting: figure 2 (b) is a schematic diagram of the experimental equipment for electromagnetic induction melting and spray casting. The main experimental process is to transfer the melted alloy to the casting crucible. Arc ignition smelting, when the alloy is completely melted, the arc ignition current is appropriately increased, so that the alloy liquid is cast into the mold along the guide tube to form; when the alloy thin strip is cooled to room temperature, the sample is removed.

[0038] 3) The main procedures of metallographic sample preparation are: sampling - embedding - polishing - polishing - etching, etc. Use 5% nitric acid alcohol solution as corrosion solution.

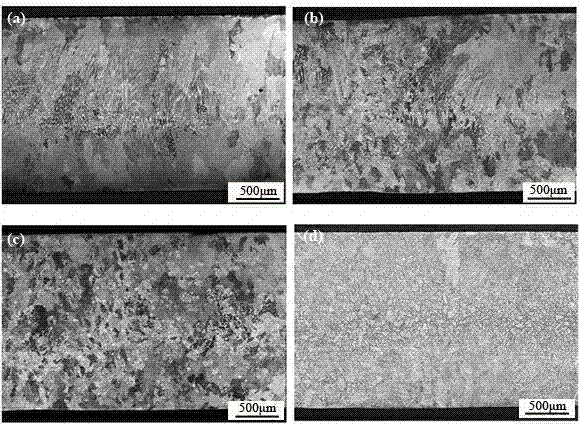

[0039] 4) Observation of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com