Finishing machine for surface of special-shaped workpiece of 5-degree-of-freedom robot

A special-shaped workpiece and robot technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of poor working environment, poor general performance, increased cost, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

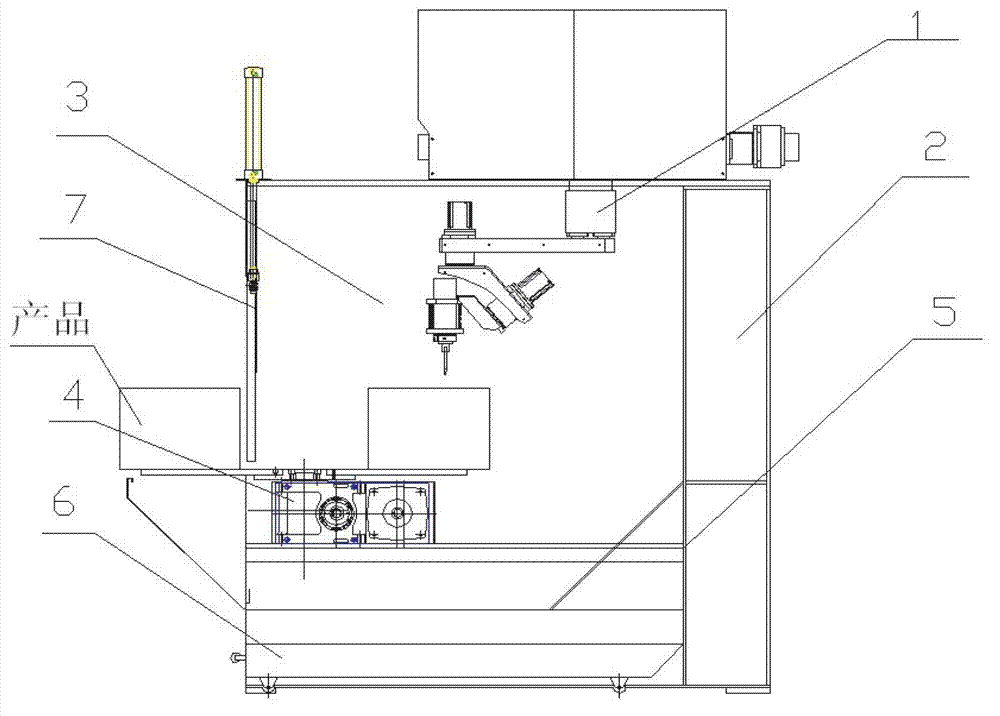

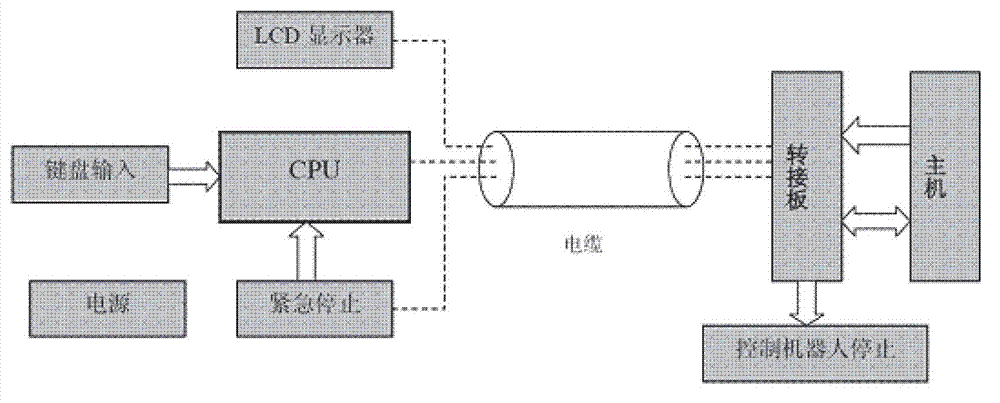

[0009] Such as figure 1 As shown, the five-degree-of-freedom robot special-shaped workpiece surface finishing machine includes a five-axis robot 1, a control system 2, an electric spindle head 3, a double-station rotary table 4, a bed 5, a scrap collection vehicle 6, and an automatic upper and lower safety door 7. There is a working platform on the bed 5, a double-station rotary table 4 is set on the platform, a scrap collection car 6 is set under the bed 5, and a five-axis robot 1 connected to an electric spindle head 3 is set on a bed 5, the five-axis robot 1 drives the electric spindle head 3 to rotate and move, and removes the burrs of the workpiece 8 on the double-station rotary table 4. The computer control system 2 controls the five-axis robot 1 to realize 360o processing of the workpiece.

[0010] The double-station rotary workbench 4 is provided with two workbenches, and the processed workpieces and the workpieces to be processed are replaced, and the waste chips are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com