Preparation method of tamsulosin hydrochloride

A technology of tamsulosin hydrochloride and tamsulosin, which is applied in the preparation of sulfonamides and organic chemistry, can solve problems such as pollution, and achieve the effects of high purity, reduced reaction time, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of R-Tamsulosin free base

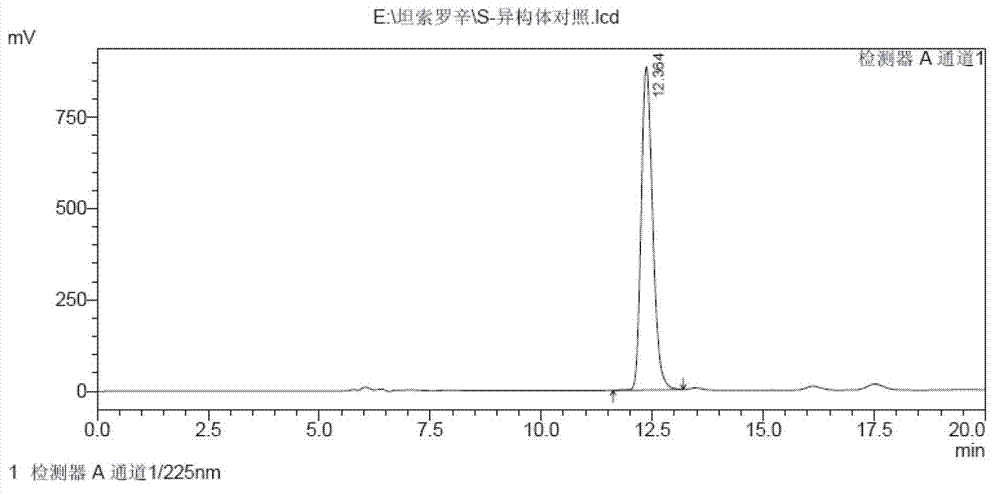

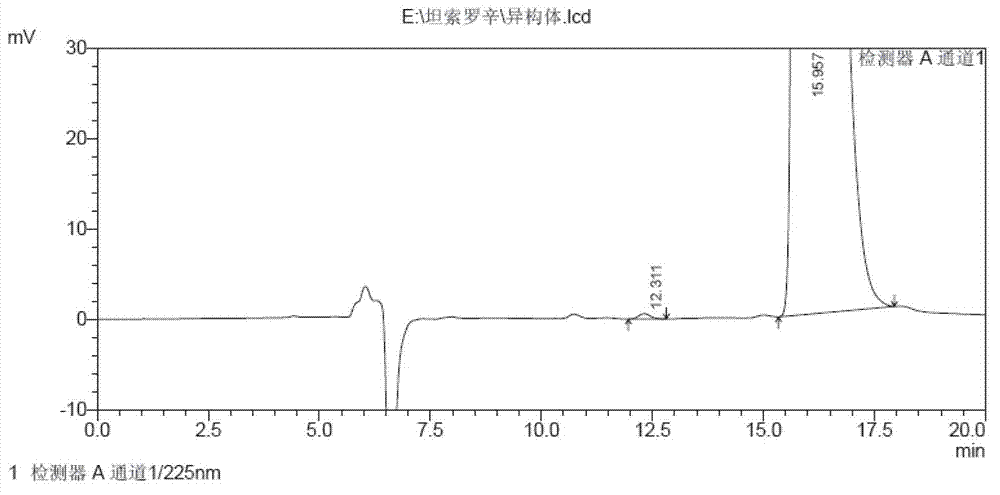

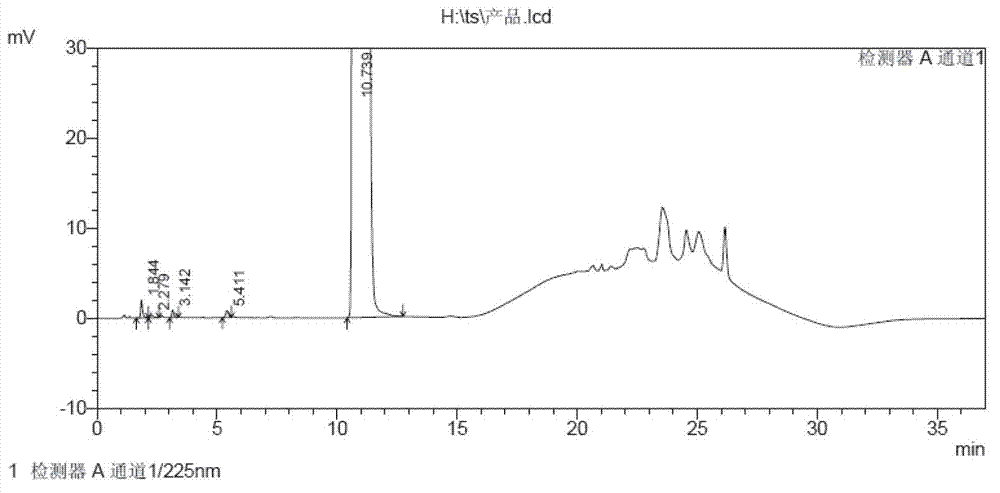

[0037] R-(-)-5-(2-aminopropyl)-2-methoxybenzenesulfonamide hydrochloride (56g; 0.2mol), o-ethoxyphenoxyethyl bromide (49g; 0.2mol) 1. Potassium carbonate (56g; 0.4mol) was added to 600ml of water, and at 85°C, it was incubated for 8 hours. After the reaction was completed, it was cooled to room temperature, filtered with suction, and the filter cake was washed with 100ml of water and 100ml of methanol, and dried to obtain 56g of R- Tamsulosin free base, add 56g R-Tamsulosin free base into 500ml of anhydrous methanol, heat to dissolve, slowly cool down to 25°C, stir and crystallize for 10 hours, filter, wash with 100ml of anhydrous methanol, and drum at 50°C After air-drying, 50 g of R-Tamsulosin free base (HPLC purity 99.92%, optical purity (chiral HPLC): S-Tamsulosin: 0.03%) was obtained.

[0038] (2) Preparation of R- tamsulosin hydrochloride

[0039] Add 50g of high-purity R-Tamsulosin free base to 400ml of anhydrous meth...

Embodiment 2

[0041] (1) Preparation of R-Tamsulosin free base

[0042] R-(-)-5-(2-aminopropyl)-2-methoxybenzenesulfonamide hydrochloride (280g; 1mol), o-ethoxyphenoxyethyl bromide (245g; 1mol), carbonic acid Potassium (276g; 2mol) was added to 4200ml of water, and kept at 90°C for 7 hours. After the reaction, it was cooled to room temperature, filtered with suction, and the filter cake was washed with 500ml of water and 500ml of methanol, and dried to obtain 280g of R-Tamsulol Add 280g of R-Tamsulosin free base to 2800ml of anhydrous methanol, heat to dissolve, slowly cool down to 25°C, stir and crystallize for 9 hours, filter, wash with 500ml of anhydrous methanol, and dry to obtain 240g of R-Tamsulosin Sorosin free base (HPLC purity 99.89%, optical purity (chiral HPLC): S-Tamsulosin: 0.05%).

[0043] (2) Preparation of R- tamsulosin hydrochloride

[0044] Add 240g of high-purity R-Tamsulosin free base to 1900ml of anhydrous methanol, stir and dissolve at 60-70°C, add hydrochloric acid ...

Embodiment 3

[0046] (1) Preparation of R-Tamsulosin free base

[0047]R-(-)-5-(2-aminopropyl)-2-methoxybenzenesulfonamide hydrochloride (280g; 1mol), o-ethoxyphenoxyethyl bromide (245g; 1mol), carbonic acid Sodium (212g; 2mol) was added to 2800ml of water, and kept at 90°C for 10 hours. After the reaction, it was cooled to room temperature, filtered with suction, and the filter cake was washed with 500ml of water and 500ml of methanol, and dried to obtain 285g of R-Tamsulol Add 285g of R-Tamsulosin free base to 2280ml of anhydrous methanol, heat to dissolve, slowly cool down to 27°C, stir and crystallize for 12 hours, filter, wash with 400ml of anhydrous methanol, and dry to obtain 250g of R-Tamsulosin Sorosin free base (HPLC purity 99.92%, optical purity (chiral HPLC): S-Tamsulosin: 0.04%).

[0048] (2) Preparation of R- tamsulosin hydrochloride

[0049] Add 250g of high-purity R-Tamsulosin free base to 2500ml of anhydrous methanol, stir and dissolve at 60-70°C, add hydrochloric acid dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com