High temperature resistant putty and its preparation method

A technology of high temperature resistance and putty, applied in the direction of filling slurry, etc., can solve problems such as filling and repairing of heat-resistant coating, and achieve the effect of excellent process performance and good static heat insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

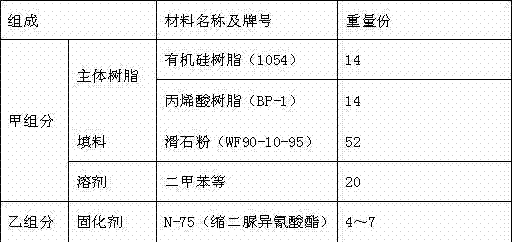

[0014] Table 1 Formula of high temperature resistant putty

[0015]

[0016] Note: The curing agent is added when the high temperature putty is prepared

[0017] Preparation method: Take silicone resin, acrylic resin, filler and solvent, mix them, stir them evenly with a nylon rod, then put them into a three-roll mill, adjust the speed ratio of the front roller, middle roller and rear roller of the three-roll mill to 1:3 : 9, the speed of the fast roller is 4-5m / s, start the three-roller mill to disperse evenly, reach the fineness required by the putty, scrape it to the discharge hopper with a scraper, and prepare the A component of the high temperature resistant putty, and the B component is solidified agent, component A and component B are packaged separately. When using, just mix the A component and the B component evenly.

Embodiment 2

[0018] Embodiment 2: performance test of high temperature resistant putty

[0019] (a) Putty preparation: Weigh 300g of component A and 15g of component B in Example 1, and scrape back and forth on the scraper to mix evenly.

[0020] (b) Scratching:

[0021] Anodization of aluminum test piece (100×100×1.2): the thickness of the aluminum test piece is 0.7mm (scratched multiple times);

[0022] Tin plating on tinplate: thickness of tinplate coating is 0.1mm;

[0023] Use multiple scraping methods to achieve the required thickness (every scraping is dried, polished and then scraped again).

[0024] (c) Curing: The test piece was dried naturally for 48 hours.

[0025] (d) Test piece test: Perform performance test on the test piece according to the relevant standards, and the test indicators are shown in Table 2.

[0026] Table 2 Performance test of high temperature thermal insulation coating

[0027] project performance requirements Test results experiment meth...

Embodiment 3

[0030] Embodiment 3: the high-temperature-resistant putty of embodiment 1 is applied on the heat-resistant coating of the second first cabin, the second second cabin, the third cabin and the fifth cabin of a certain new model:

[0031] (a) Putty preparation: Mix component A and component B on the scraper evenly, and scrape back and forth with a scraper.

[0032] (b) Scratching: Scrape high-temperature-resistant putty on the sunken parts of the outer surface of the heat-resistant coating of the cabin, the butt joints of the cabin, and around the antenna. After each coating and scraping, it is dried and then polished and then scraped again to ensure that the outer surface of the coating is dense and smooth. Excessively sleek.

[0033] (c) Curing of the putty layer: the curing of the putty layer is natural drying for 48 hours.

[0034] (d) Usage: From the analysis of the usage of old products and new models, high temperature resistant putty can be mass-produced to meet the needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com