Drying cylinder surface repairing agent, drying cylinder surface repairing method and drying cylinder

A surface repairing and repairing agent technology, applied in textiles and papermaking, papermaking machines, dryers, etc., can solve the problems of increased papermaking costs, consumption of peeling and sticking agent, occurrence of shock marks or sand holes, etc., to increase the degree of lubrication , Increase the adhesion performance and ensure the effect of the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

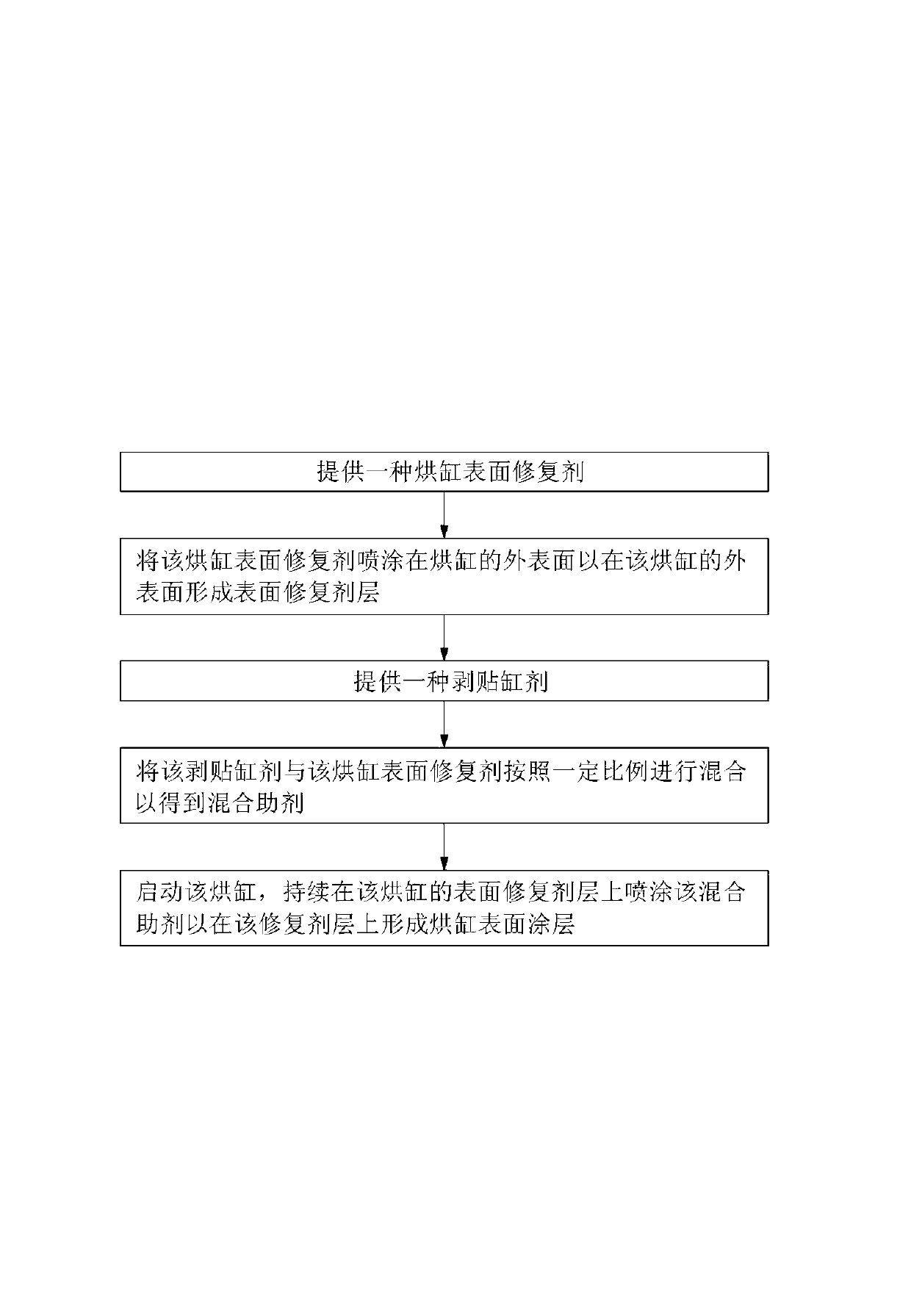

Method used

Image

Examples

Embodiment Construction

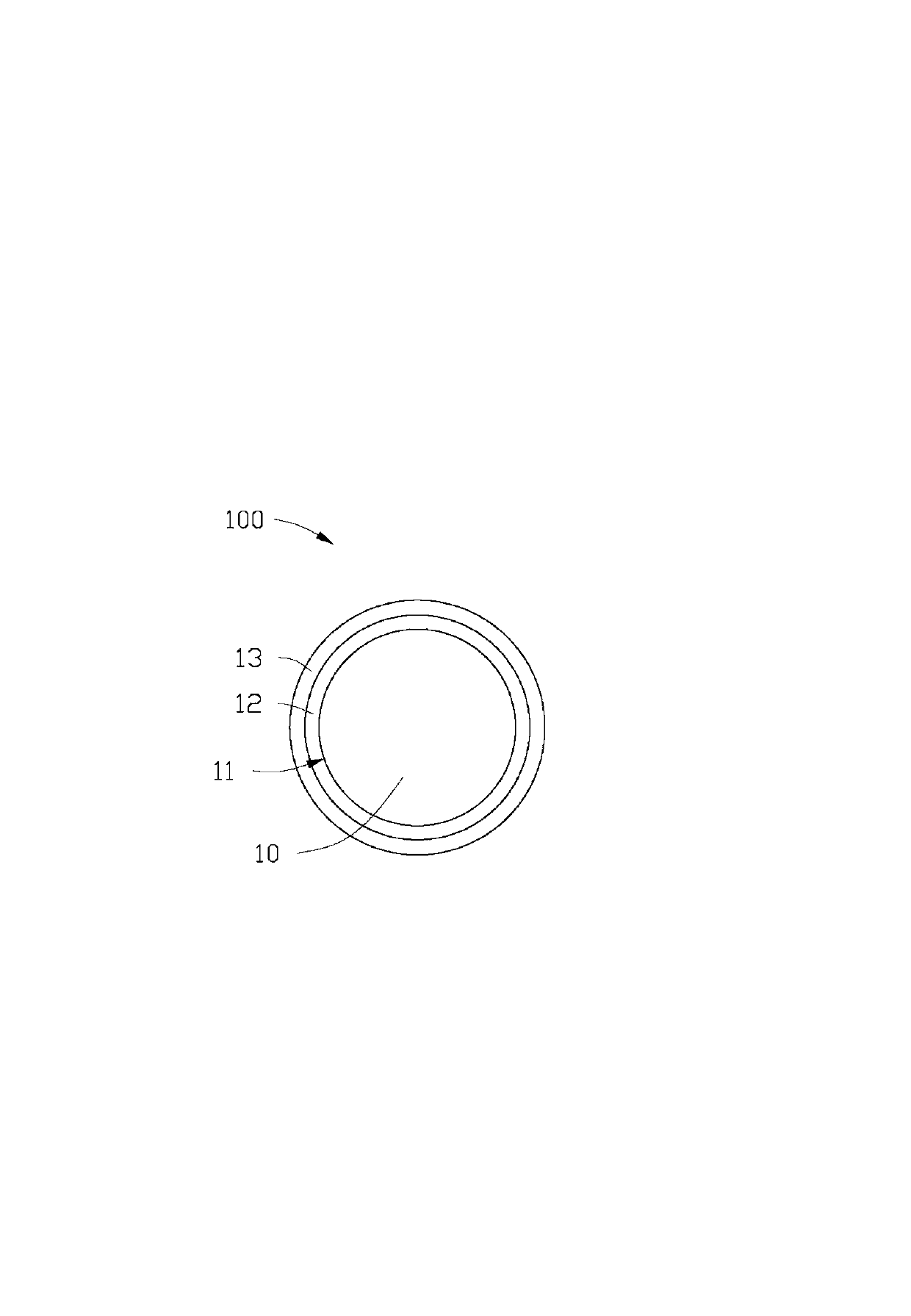

[0015] The first embodiment of the present invention provides a drying cylinder surface repair agent, which is used for filling and repairing surface defects such as shock marks or sand holes on the outer surface of the drying cylinder.

[0016] The main components of the dryer surface repair agent include metal compound solid lubricants, cationic polymers and water. In terms of mass, in the dryer surface repair agent, the content of the metal compound solid lubricant ranges from 2% to 5%, the cationic polymer content ranges from 5% to 15%, and the water content ranges from 80% to 90%.

[0017] Wherein, the metal compound solid lubricant is selected from one of metal oxides, halides, sulfides, selenides, borates, phosphates, sulfates and organic acid salts.

[0018] Specifically, the metal oxide solid lubricant includes lead oxide, trilead tetraoxide, antimony oxide, antimony trioxide, dichromium trioxide, titanium oxide, zirconium oxide, iron oxide, ferric oxide, ferric oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com