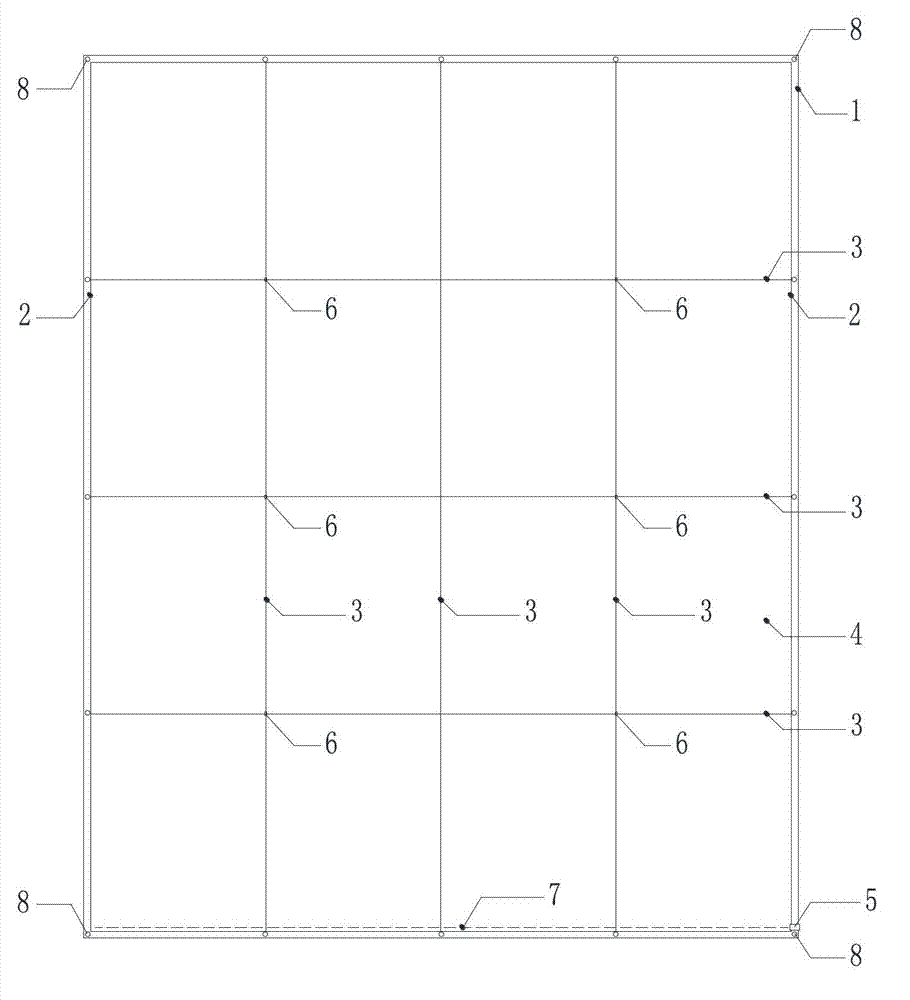

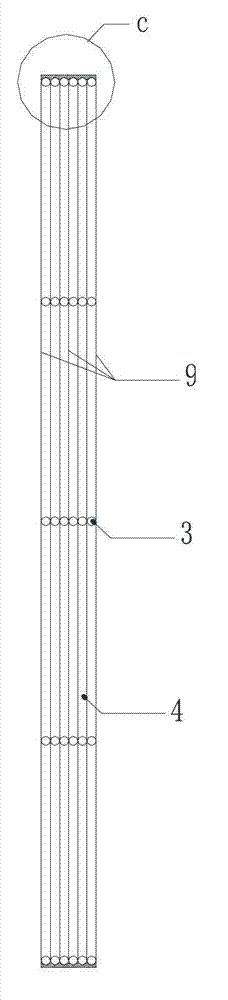

Multi-layer aeration combined film body for performing heat preservation on building

A technology of building thermal insulation and composite membranes, which is applied in thermal insulation, building components, fire doors, etc., can solve the problems of increased thickness of thermal insulation layer, complex building structure, unscientific structure, etc., and achieves reduced construction costs, simple production process, and easy storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

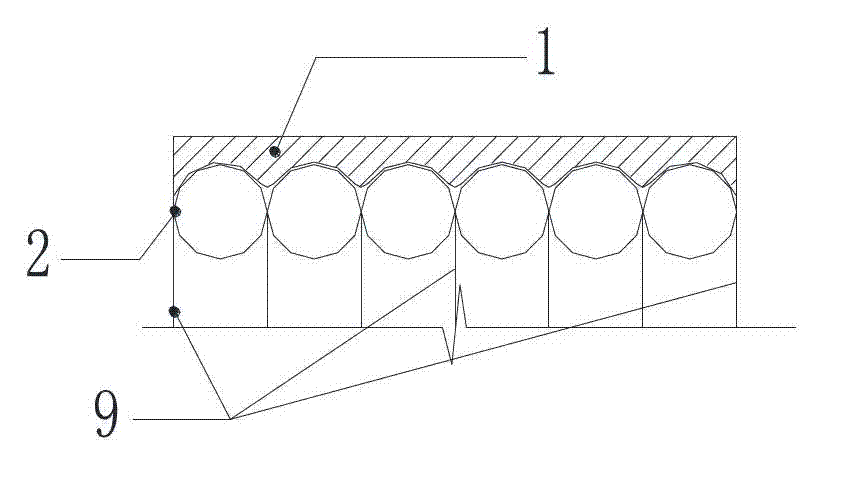

[0023] The above-mentioned composite film with six layers of flexible film was tested in the laboratory. When the double-layer LOW-E window is not added with the above-mentioned composite film, the heat transfer coefficient is measured to be 2.5. The thermal coefficient drops to 0.7.

example 2

[0025] The above-mentioned composite film body with seven layers of flexible film was tested in the laboratory. When the above-mentioned composite film body was not added to the ordinary double-layer thermal insulation window, the heat transfer coefficient was measured to be 2.7. After the above-mentioned composite film body was attached, it The heat transfer coefficient drops to 0.9.

example 3

[0027] The above-mentioned composite film body with eight layers of flexible film was tested in the laboratory. When the above-mentioned composite film body was not added to the ordinary window, the heat transfer coefficient was measured to be 3.5. After the above-mentioned composite film body was attached, the heat transfer coefficient Decrease to 1.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com