Diamond-like carbon membrane piston ring

A piston ring and carbon film technology, which is applied in the field of piston rings, can solve the problems of wear resistance, elasticity and service life of the piston ring, such as the unsatisfactory bonding strength between the diamond-like carbon film layer and the base material of the piston ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and examples.

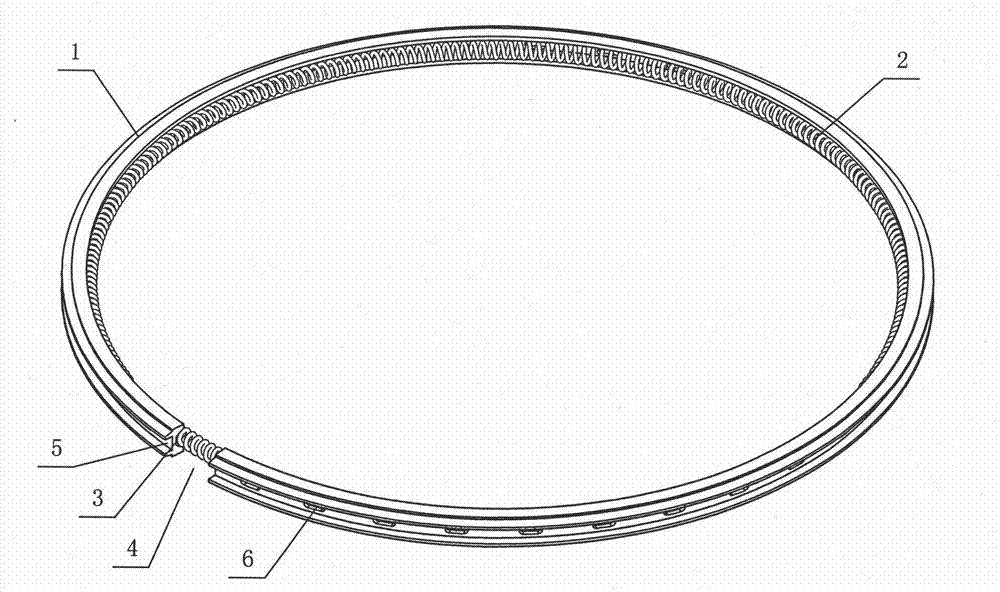

[0016] The structure of the piston ring designed by the present invention takes the oil ring of the piston ring in the engine as an example figure 1 As shown, it consists of a ring body 1 and a spring 2, wherein the coil spring 2 is tightly sleeved on the recessed part 3 of the ring body 1, and a stretched gap 4 is formed at one end of the ring body 1, On the outer periphery of the ring body 1 is a concave ring groove 5 , and on the bottom of the concave ring groove 5 there are a plurality of through holes 6 distributed in the circumferential direction.

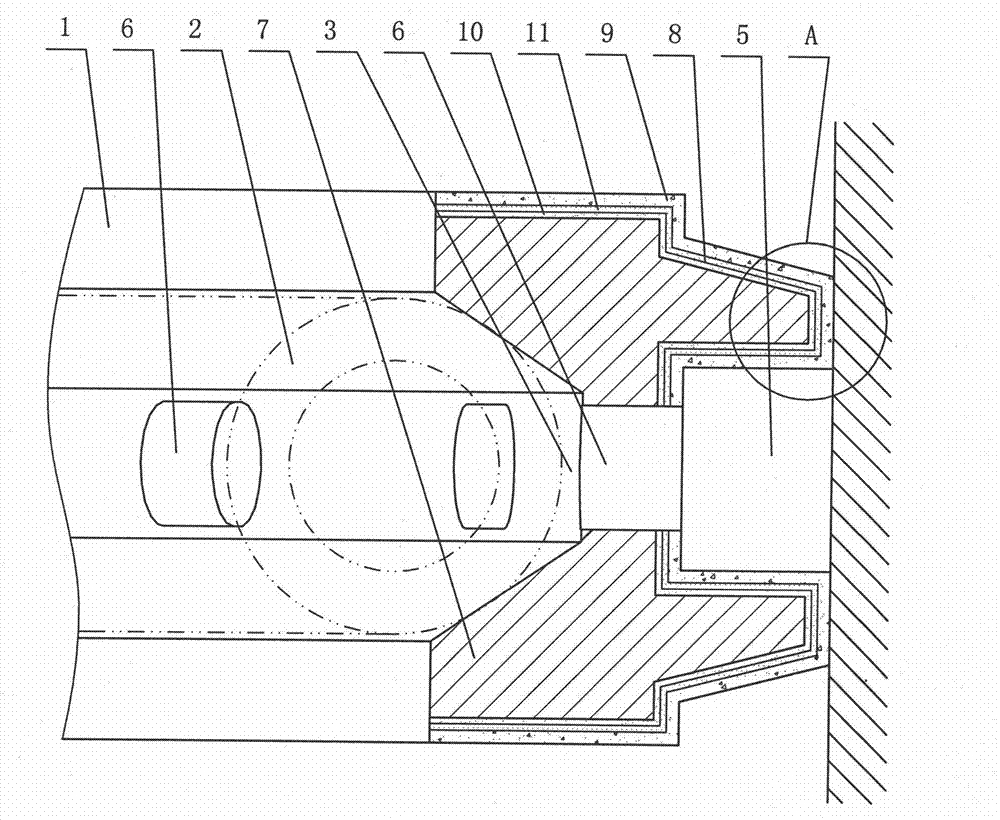

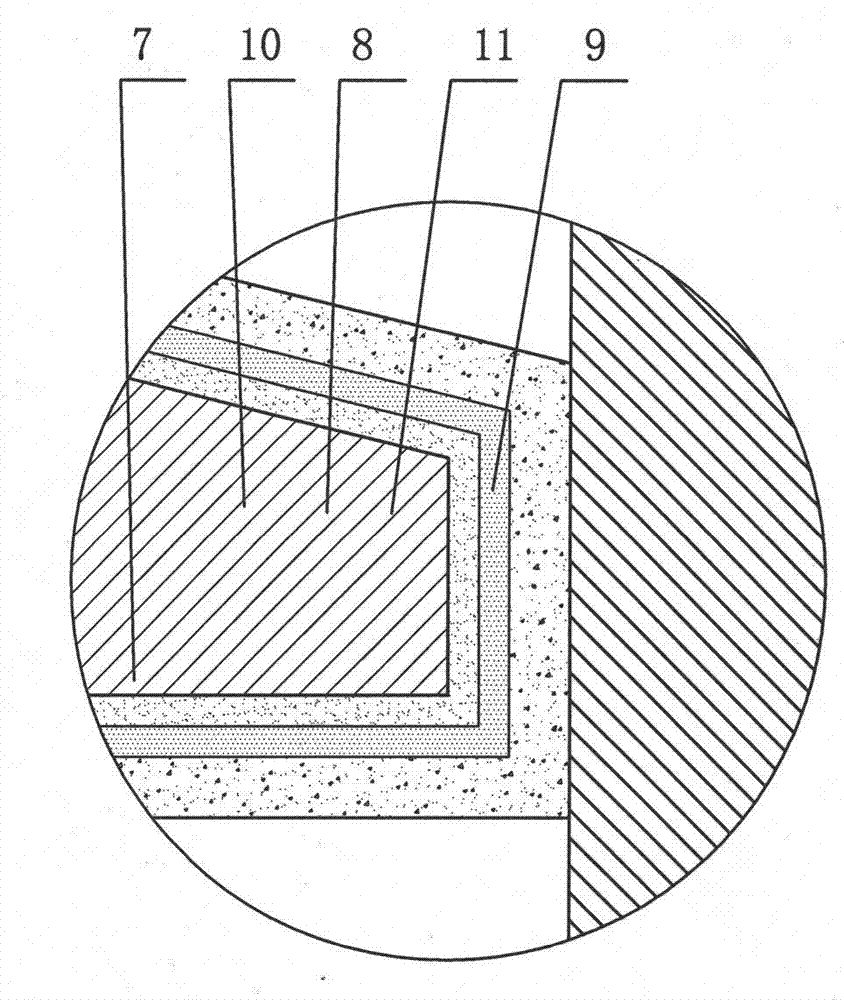

[0017] figure 2 , image 3 It is a cross-sectional view of the piston ring. It can be seen from the figure that the outer layer of the base material 7 of the ring body 1 is sequentially combined with a multi-layer intermediate layer 8, and the outer periphery of the intermediate layer 8 is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com