Brake disc of high-speed train

A technology for high-speed trains and brake discs, applied in the directions of brake discs, brake types, brake components, etc., can solve the problems of unreasonable composition matching of alloy forged steel, low temperature impact toughness of materials, and reduction of material plasticity and toughness. , to achieve the effects of excellent comprehensive mechanical properties, improved tensile strength, and simple forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

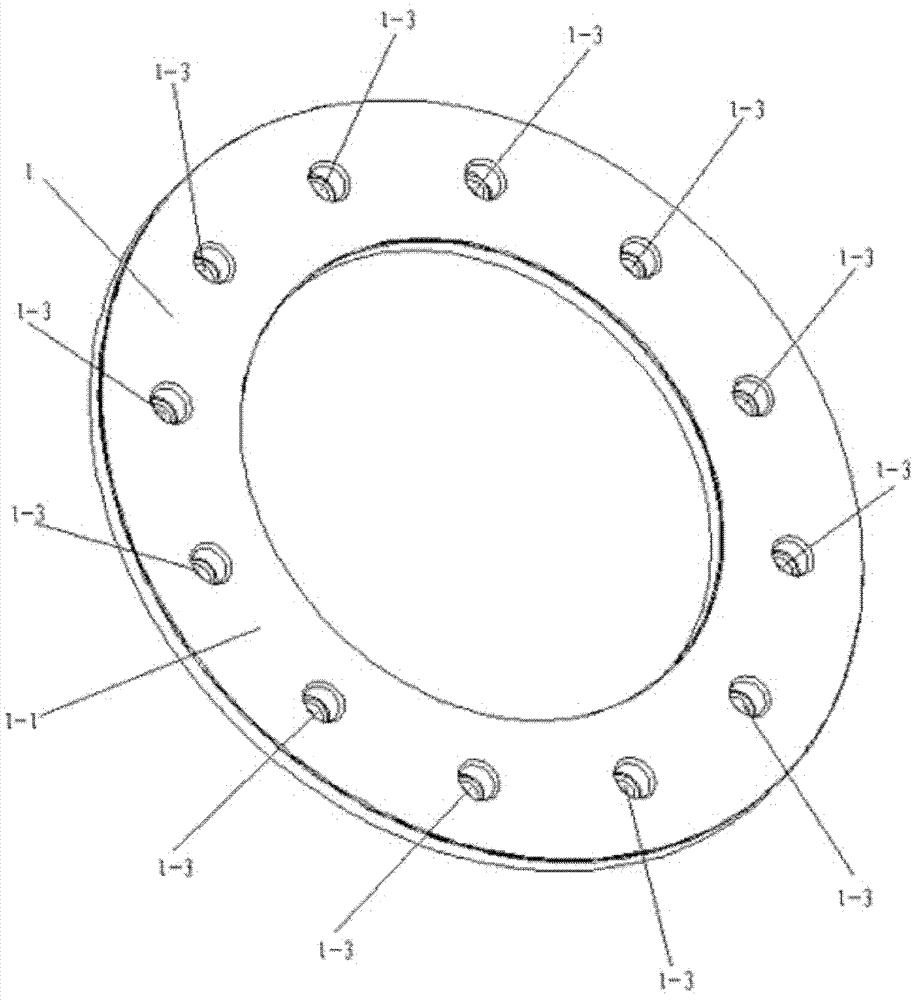

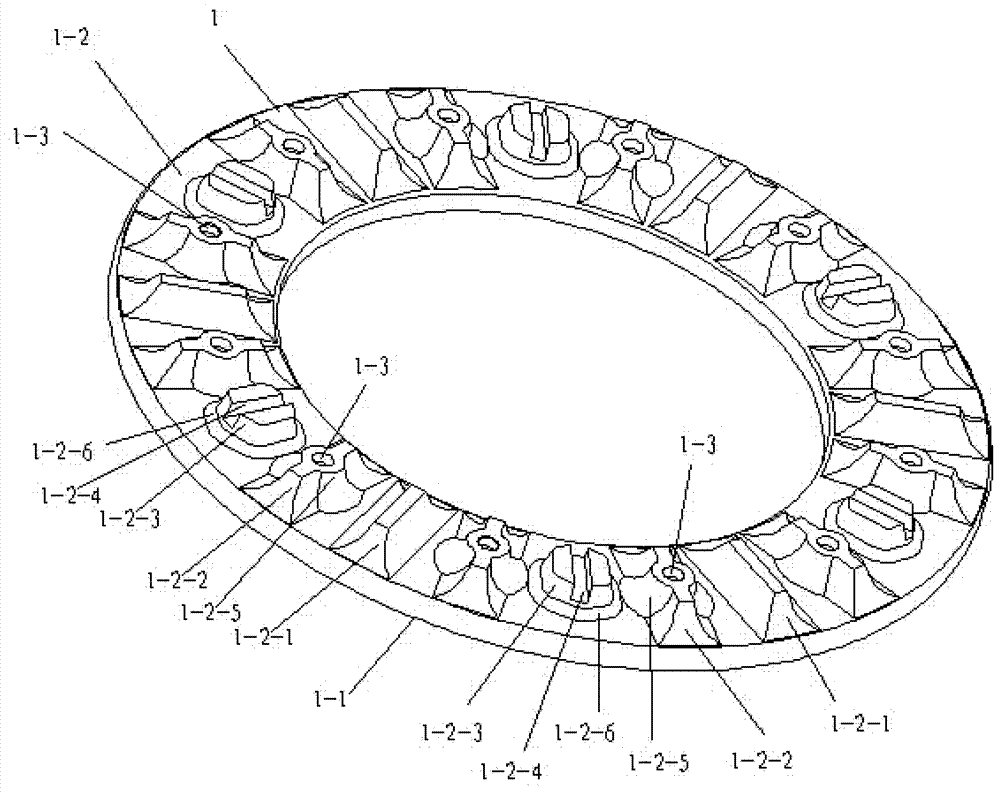

[0069] see figure 1 , 2 As shown, a high-speed train brake disc includes a disc body 1 with a middle hole. The disc body 1 has a friction surface 1-1 and an inner surface 1-2 located behind the friction surface 1-1. The disc body 1 is evenly distributed There are several installation holes 1-3, and the inner surface 1-2 of the disc body 1 is integrally forged with a plurality of first radial plate-shaped heat dissipation ribs 1-2-1, second radial plate-shaped heat dissipation ribs 1- 2-2 and the boss 1-2-3, the sides of the first radial plate-shaped heat dissipation rib 1-2-1, the second radial plate-shaped heat dissipation rib 1-2-2 and the boss 1-2-3 are all With a draft angle, the mounting hole 1-3 passes through the second radial plate-shaped cooling rib 1-2-2, and the boss 1-2-3 has a radial pin groove 1-2-4.

[0070] see figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com