Three-dimensional afforesting structure component and three-dimensional afforesting method

A technology of three-dimensional greening and structural components, which is applied in the field of greening and cultivation, can solve the problems of many materials, difficult installation, and non-compliance with energy saving and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

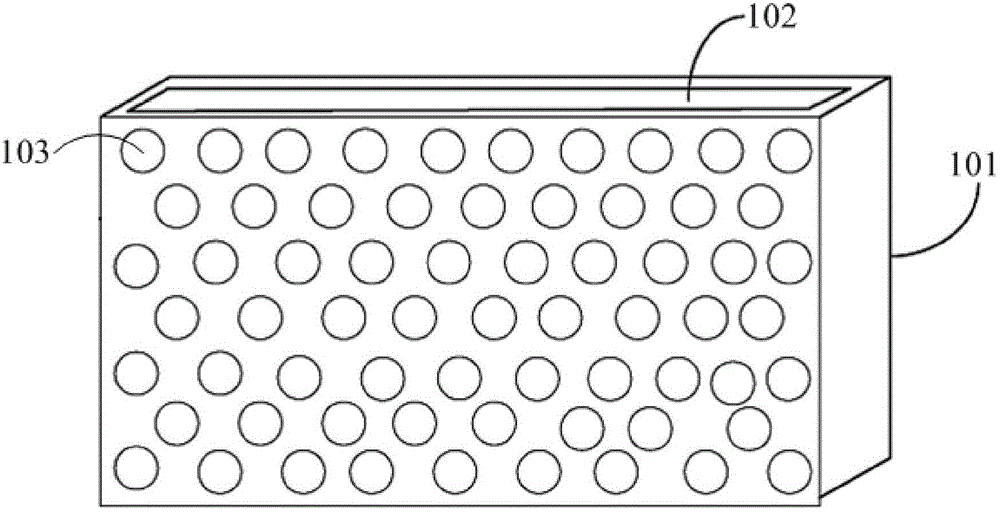

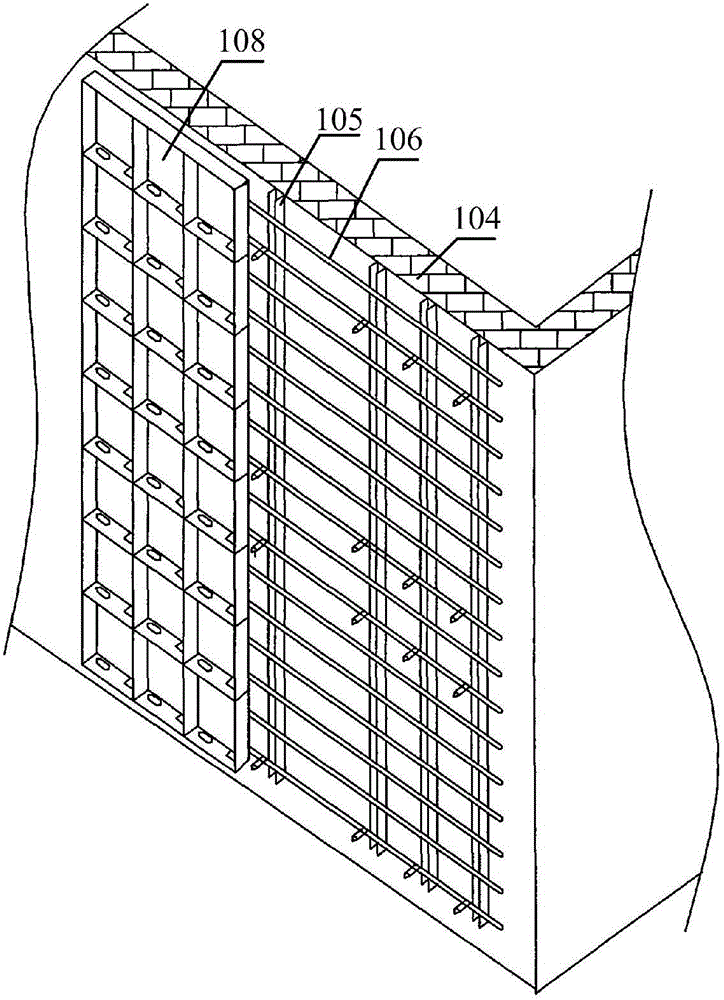

[0084] see Figure 6-8 As shown, a three-dimensional greening structure assembly includes a base body 1, a bag body 2 is arranged on the base body 1, and the base body 1 and the bag body 2 are made of the same anti-ultraviolet, flexible, breathable, water-permeable, and soil-impermeable non-woven fabric The bag body 2 is equipped with a plant growth material 15, and an isolation layer 17 is arranged between the bag body 2 and the base body 1, which can prevent plant roots from penetrating toward the side of the base body.

[0085] In this embodiment, ten bags 2 are arranged on the base 1, and are divided into two rows and staggered and sewn on the base 1. The bags are open-shaped bags, and plant growth materials 15 are housed in the bags 2. Plants provide a growing environment, eg, the growing material is soil or organic soil. Simultaneously, water-absorbing material 16 is also housed in the bag body, which can absorb water and provide water for plant growth.

[0086] The th...

Embodiment 2

[0088] see Figure 9-10 As shown, the difference between this embodiment and the first embodiment is only in the area of greening. In this embodiment, the area to be greened is the circular cylindrical surface 5 of the cylinder, while the greened area in Embodiment 1 is the square wall surface of the wall.

[0089] The three-dimensional greening method of the present embodiment: first coat the adhesive along the cylinder surface 5, then attach the base body 1 of the assembly to the cylinder surface 5, and pass the male and female joints (for example, the joints are Velcro 14) for fast locking, after the adhesive is solidified and the matrix 1 is firmly combined with the cylinder 5, put the pre-mixed water-absorbing material and plant growth material into each bag body 2, and then put it into each bag body 2 Plants 4 are planted in the bag body 2 and watered or drip-irrigated with water as required. An isolation layer 17 is provided between the bag body 2 and the base body ...

Embodiment 3

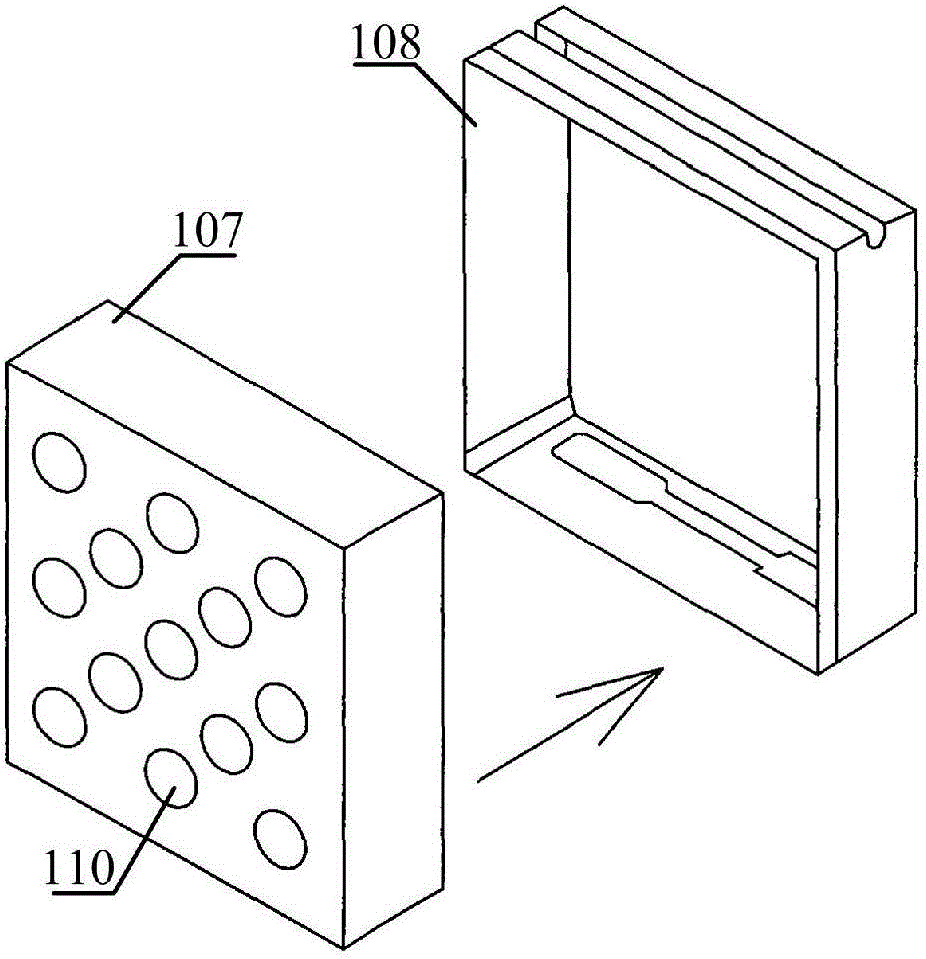

[0091] The main difference between this embodiment and the above two embodiments lies in the way of planting plants. In this embodiment, the plants are first planted in the pot, and then placed in the bag as a whole, while the above two embodiments both adopt the method of directly planting the plants in the bag.

[0092] The three-dimensional greening method of this embodiment: firstly, uniformly coat the adhesive on the wall, and then attach the components to the wall as a whole. After the adhesive is cured so that the components are firmly combined with the wall, the A single pot with evenly mixed water-absorbing material and plant growth material and planted with plants is respectively installed in each bag, and is watered or drip-irrigated with water as required, and the water-absorbing material in the pot can save water. Those skilled in the art can easily imagine that, in the above steps, the seeds of plants can be directly sown in the pot and watered, and the purpose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com