Preparation method of frozen noodles containing pre-gelatinized hydroxylpropyl starch

A technology for pregelatinizing hydroxypropyl and starch, applied in the field of food processing, can solve the problems of destroying the taste of noodles, high water content of frozen noodles, large ice crystals, etc. and the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

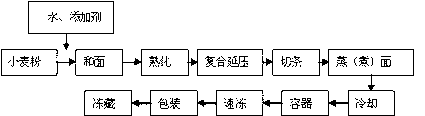

Image

Examples

Embodiment 1

[0017] a, preparation of pregelatinized hydroxypropyl starch:

[0018] Take by weighing 100g tapioca starch, add 300mL the distilled water that adds the anhydrous sodium sulfate of starch dry weight 12% and the sodium hydroxide of 1.2%, be made into the starch milk of concentration 30%, after stirring, put into reactor, And put the reactor into a water bath, slowly add 13% propylene oxide with a dry basis weight of starch with a pipette at a temperature of 18°C, seal it, and stir for 30 minutes at this temperature, so that the propylene oxide and Mix the starch evenly, then transfer it to a water bath at 50°C and stir for 20 hours, adjust the pH value to 6.7 with 3% dilute hydrochloric acid, transfer it to a centrifuge tube, centrifuge at a speed of 5000rpm / min for 10min, and wash three times by centrifugation. Then vacuum-dry at 60°C and pulverize to obtain hydroxypropyl starch; prepare hydroxypropyl starch with water to make a starch slurry with a concentration of 5%, stir a...

Embodiment 2

[0022] a, preparation of pregelatinized hydroxypropyl starch:

[0023] Take by weighing 100g tapioca starch, add 250mL the distilled water that adds the anhydrous sodium sulfate of starch dry basis weight 15% and the sodium hydroxide of 1.2%, is made into the starch milk of concentration 40% (all the other steps are identical with embodiment 1);

[0024] b. The difference between this step and step b of Example 1 is that the added amount of the pregelatinized hydroxypropyl starch is 1.5% of the flour weight.

[0025] After the product prepared in this example was frozen and stored at -18°C for one month, the quality of the finished product after cooking was significantly improved. The noodles were milky white in color, good in elasticity, and smooth in taste. The quality was the same as that of fresh noodles, and the dissolution rate was small. The specific texture parameters of the frozen noodle product (sample) prepared by this method and the ordinary frozen noodle product (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com